Our achievements

Our achievements

in large scales in the rehabilitation innovative means.

Our materials enable to make the advanced technologies

more available for the physically challenged people.

The research results of MODENGY

anti-friction solid-film coatings for piston skirts of the highly boosted diesel engines have been published in Journal of Friction and Wear, the international journal.

The researches were held at the tribology laboratory of the Institute of Mechanics Issues named by

A. Ishlinsky in Moscow. This scientific work was held with support from the Defense Ministry, and the Science and Higher Education Ministry of the Russian Federation as part of the state assignment.

The research has revealed that using solid-film coatings enable to achieve a five-fold reduction in friction losses, and to extend the service life of the highly boosted diesel engine parts.

successfully at the sea offshore area as a part of the

Environment Protection Program while developing

the sea oil and gas deposits

The offshore oil platforms fastening parts operate

under conditions

of temperature drops, high humidity,

and exposure to aggressive environment.

while designing transport for the Arctic

exploration program

In our large country, machinery can be operated in various climate zones.

While designing the transport friction units, it is necessary to provide their

effectiveness at - 40 °С, - 60 °С, and even - 70 °С.

MODENGY anti-friction solid-film

coatings guarantee friction units operability at low and cryogenic temperatures.

ICE pistons mass production

at the leading motor plants

without MODENGY coatings.

MODENGY materials have gained approval

of the testing center of the Research and Building

Metal Constructions Design Institute

named after Melnikov.

for extremely high temperatures has been successfully

completed at the Moscow Aviation Institute.

MODENGY coatings are applied onto the gas-dynamic bearing

petals

of the micro-turbines. This protects the micro-turbine

shaft against wear at service temperatures up to + 550 °С,

and significantly extends its service lifetime.

high efficiency of MODENGY coatings technology in the machine

building industry at the Polymer Composites

and Triboloby-2019 Conference.

The results of the scientific researches were presented at the METS-2021 International Scientific-Technical Conference in Azov town that was held with support of the Science and Higher Education Ministry of the RF, the Donskoy State Technical University, and Rostvertol, PJSC, the Helicopters of Russia Holding. The contracts on a number of projects relate to the tests, and the applications of MODENGY reversible adaptable coatings at high-tech equipment production, were signed between the engineers and the scientists at the Conference.

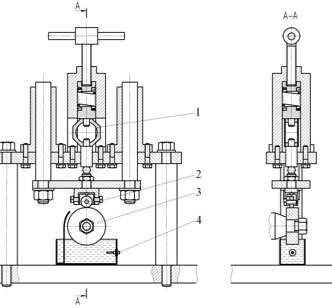

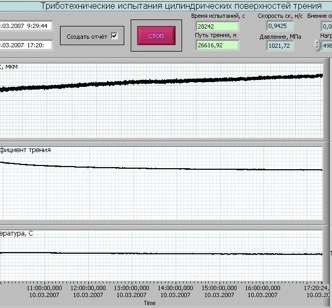

The laboratory’s stands have been verified and certified at the authorized methodological center.

The capabilities of the laboratory enable to the machinery producers to predict operational properties of the friction units already on their design stage.

The testing equipment enables to estimate such important parameters as friction coefficient, and wearing intensity according to ASTM G99 standard, anticorrosive properties according to GOST 30630.2.5 (IS0 9227), as well as frictional heating.

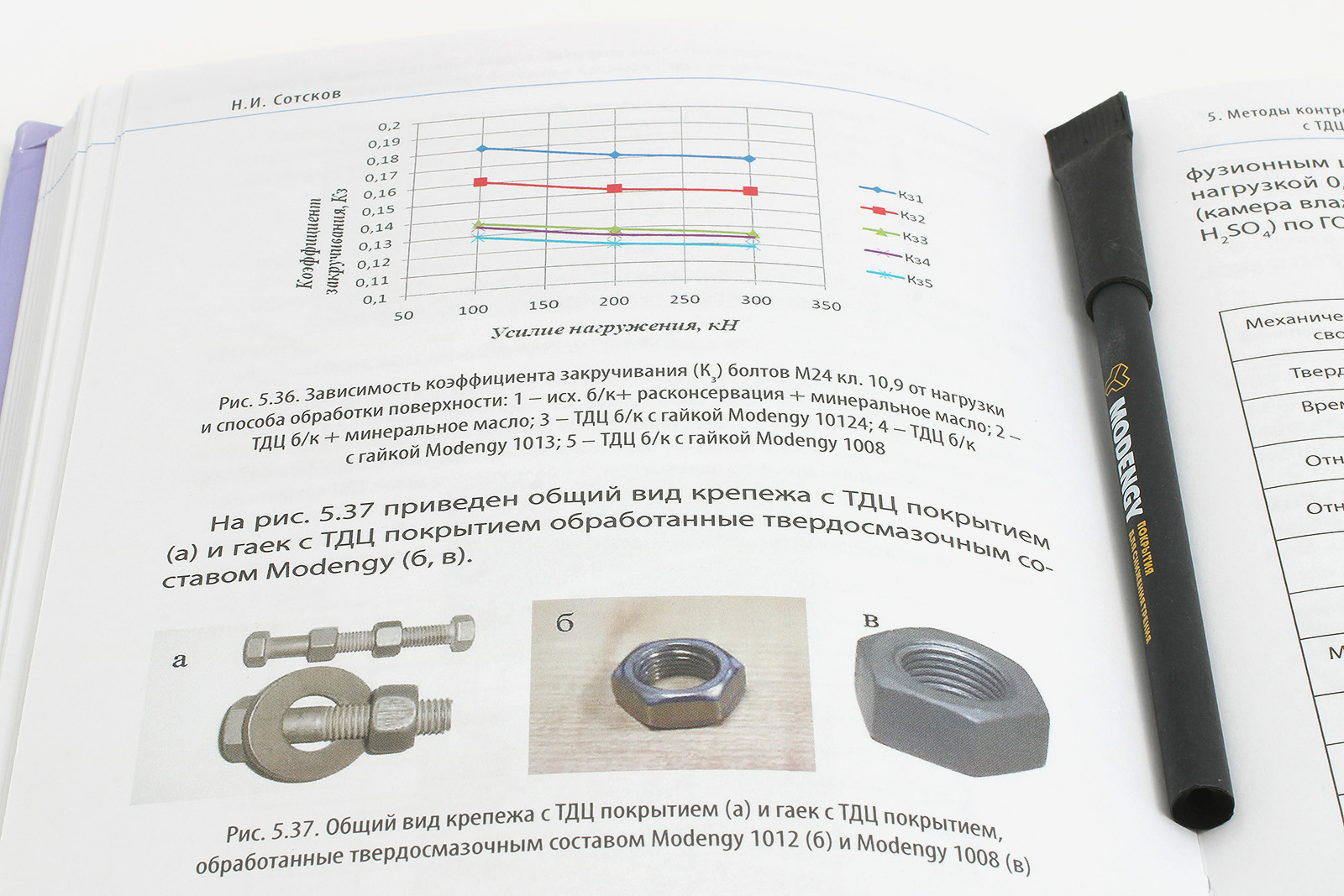

In year 2021, the book by Mr. N. I. Sotskov, the Candidate of the Technical Sciences, the Head of the Laboratory on researches of steel corrosion and fastener protection, has been published. Recommendations on use of MODENGY solid-film coatings for fasteners are given in this work. A positive conclusion based on the tests results for detecting K3 torsion coefficient depending on loading effort has also been given.

Application of these solid-film coatings enables to stabilize torsion coefficient, and to provide mounting reliability, to exclude the labor-intensive operations on cleaning and lubricating the fasteners at the mount site.

The book has been released released by the Innovative Machine Building publishing house under general scientific edition by Professor Anatoly G. Suslov, a Doctor of Engineering, an honoured man of science and engineering of the RF. Two fundamental scientifically based trends on of technological provision, and improvement of the machine building items reliability are expounded in this book.

This book is intended for designers and process engineers engaged in designing and developing the machine building items technological processes as well as for the employees of the design engineering firms, and scientific organizations of the machine building profile, professors and teaching staff, postgraduate and graduate students of the technically oriented educational institutions.

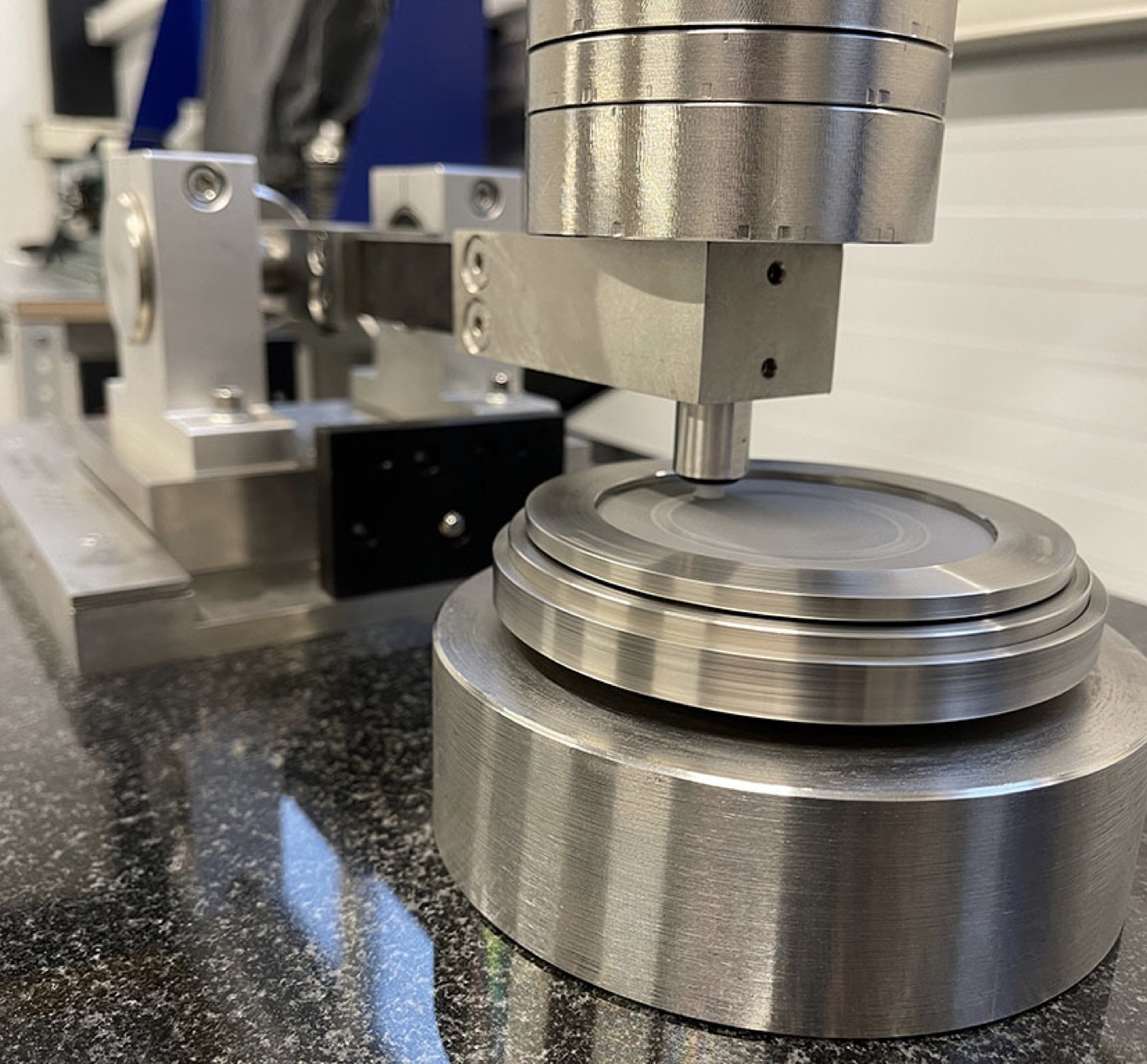

The laboratory is equipped with high-tech specialty equipment to research and design anti-friction materials with unique properties.

This new scientific and technical subdivision has tasks of quite a wide range of researches in the field of developing MODENGY solid-film coatings, pastes, and dry lubricating materials.

RU

RU

EN

EN