About MODENGY coatings

About MODENGY coatings

MODENGY ASCs (Anti-Friction Solid-Film Coatings) are materials consisting of film-formers, solvents, highly dispersed particles of the solid lubricating materials as well as some functional additives.

After being applied onto a specially prepared surface, a thin composite layer forms which has high protective and lubricating properties. It provides efficient dry lubrication, and corrosion protection.

After being applied onto a specially prepared surface, a thin composite layer forms which has high protective and lubricating properties. It provides efficient dry lubrication, and corrosion protection.

MODENGY Anti-Friction Solid-Film

Coatings Technology Advantages

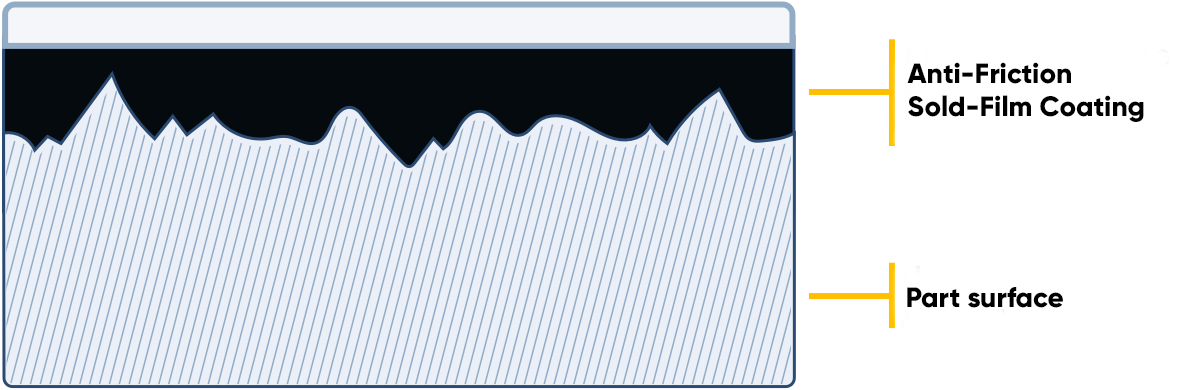

MODENGY coating scheme

The composite layer formed by MODENGY Coatings is the binding substance matrix, tightly adhered to a substrate, whose cells are filled with highly dispersed particles of a solid lubricating material. The microroughness hollows of the surface are being filled, which increases its bearing area, and bearing capacity.

The coating has high compression resistance, and little shear resistance. As a result, the dry friction coefficient reaches the values of hundredths of one at the contact pressure commensurable with flow point of the substrate material.

We develop and release coatings based on organic and non-organic binders as well as solid lubricating materials of various chemical nature.

We develop and release coatings based on organic and non-organic binders as well as solid lubricating materials of various chemical nature.

Anti-Friction Solid-Film coating composition

Solid lubricating materials:

- Molybdenum disulfide

- Tungsten disulfide

- Polytetrafluorethylene (PTFE)

- Boron nitride

- Graphite

- Сalcium fluorides, and Barium fluorides

- Metal oxides

They define:

– Anti-friction features

– Coating resistance against wearing-off

– Coating resistance against wearing-off

Film-formers (binders):

- Epoxy

- Formaldehyde

- Polyamide-imide

- Acrylic

- Polyurethane

- Organosilicon

- Silicate

- Phosphatic

They provide:

– Coating adhesion to the base

– Protective properties

– Physical and mechanical characteristics

– Chemical resistance

– Protective properties

– Physical and mechanical characteristics

– Chemical resistance

Our production facilities enable apply the coatings onto the parts of almost any configuration. MODENGY Anti-Friction Solid-Film Coatings have successfully proofed their efficiency, and are used in energy, machine-tool manufacturing, automotive, oil-and-gas, and other industries.

Contact us for solutions of your engineering challenges!

Request Information Show works

Contact us for solutions of your engineering challenges!

RU

RU

EN

EN