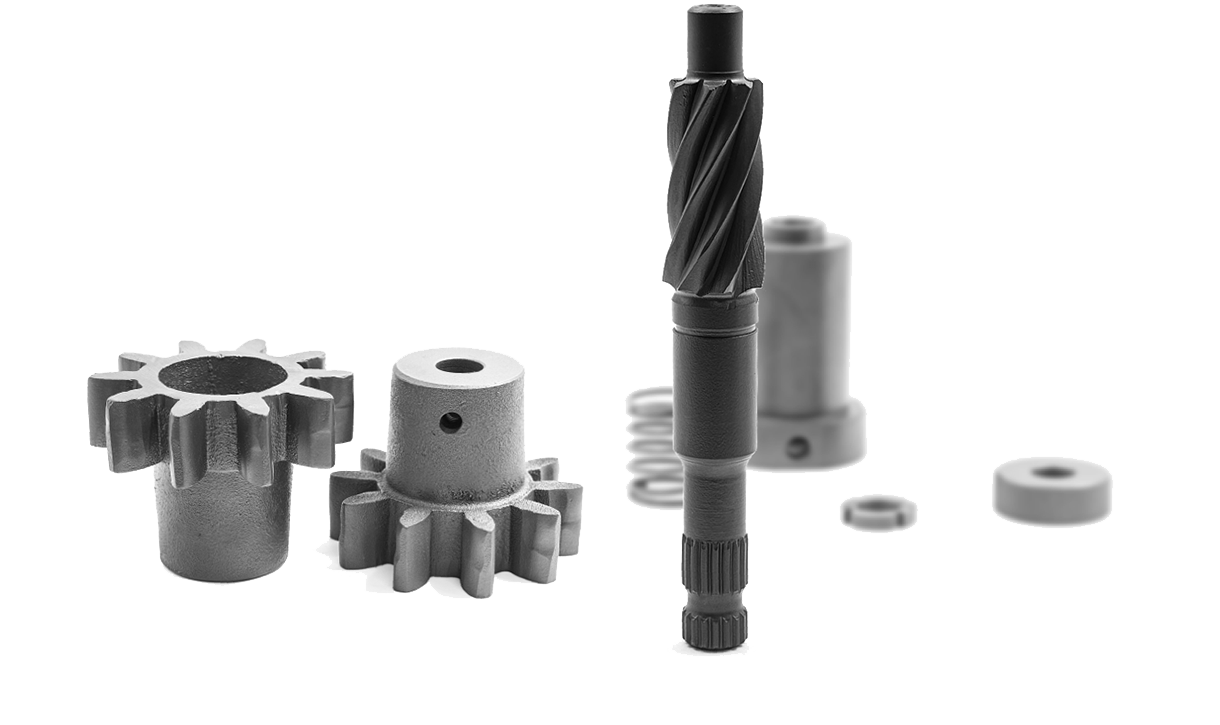

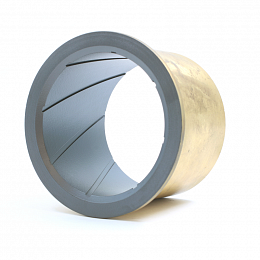

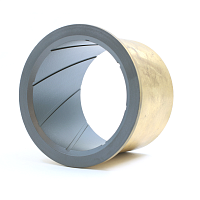

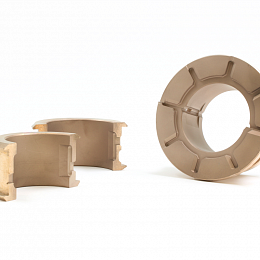

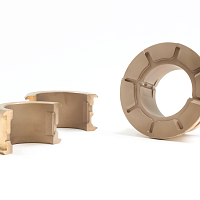

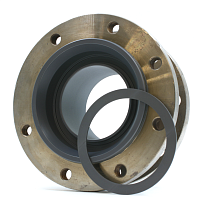

Examples of MODENGY coatings applications

MODENGY Coatings

Anti-friction solid-film coatings, pastes, dry adaptive lubricating materials, associated chemicals and equipment.

Go to the Products

You can meet us at the exhibitions

and conferences

21-24 May 2024

GAS.OIL.TECHNOLOGIES – 2024

Expected

4 June

High-quality fasteners - reliability of machines and metal structures – 2024

Expected

26-27 June 2024

East Russia Oil and Gas Forum 2024

Expected

July 2024

Bryansk Field Day

Expected

12-18 August 2024

INTERNATIONAL MILITARY-TECHNICAL FORUM ARMY-2024

Expected

19-22 August 2024

MIMS Automobility Moscow 2024

Expected

20-23 August 2024

International exhibition of automotive industry InterAuto 2024

Expected

26-28 August 2024

TATOILEXPO-2024, INTERNATIONAL EXHIBITION

Expected

26-27 September 2024

Wire - fasteners - 2024

Expected

8 october - 11 october 2024

27TH INTERNATIONAL SPECIALIZED EXHIBITION OF NATURAL GAS INDUSTRY AND TECHNOLOGY FOR GAS FACILITY

Expected

22-24 October 2024

ExpoCoating Moscow

Expected

October 22-24, 2024

RUSSIAN OIL AND GAS TECHNICAL CONGRESS – 2024

Expected

October 22–24, 2024

FastTec – 2024. The 20th Anniversary International Exhibition of Fasteners

Expected

22 - 24 October 2024

PCVExpo – 2024. The 23rd International exhibition of industrial pumps, compressors, valves, actuators and engines

Expected

22 - 24 October 2024

Heat&Power – 2024. The 9th International specialised exhibition of industrial boilers, heat exchange and power generation equipment

Expected

22 - 24 October 2024

TECHNOFORUM – 2024

Expected

29 October-01 November 2024

Metal-Expo’2024, the 30th International Industrial Exhibition

Expected

10 - 13 DECEMBER 2024

Comtrans International – 2024

Expected

23-25 April 2024

MiningWorld Russia 2024

Passed

15 - 18 April 2024

NEFTEGAZ 2024

Passed

APRIL 24-26, 2024

The 26th CORROSION PROTECTION INTERNATIONAL EXHIBITION & CONGRESS

Passed

24-26 april 2024

ST. PETERSBURG TECHNICAL FAIR

Passed

15 - 18 April 2024

TIRES & RUBBER 2024

Passed

9–11 April 2024

VacuumTechExpo 18th International Exhibition of Vacuum and Cryogenic Equipment

Passed

6 - 7 February 2024

NAIS 11th National Aviation Infrastructure Show

Passed

23-24 January 2024

RUPLASTICA-2024

Passed

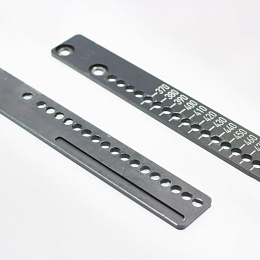

Our articles and publications

Learn more about application of the MODENGY Anti-Friction Solid Lubricating Coatings Technlology to reduce friction, wear, and to protect against corrosion

Go to the Articles

News

26.04.2024

Use of MODENGY 4002 solid-film paste based on molybdenum disulfide provides smooth noiseless movement of the lifting elements of the disabled people transporting equipment.

View more news All the News

RU

RU

EN

EN