MODENGY 1005 / 1066

Excavator sliding bearings

Image source:

shutterstock.com

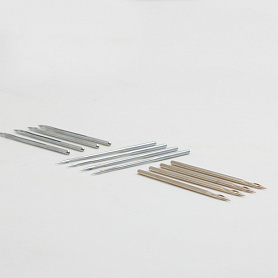

While operating of the open-mine excavators, eyelet bushings, and spherical bearings are exposed to enormous loads which cause serious damage of the parts. When the bushings are worn, it causes shaking and vibration of the excavator buckets during operating which causes breaking of the other parts.

MODENGY 1005 based on molybdenum disulfide, and MODENGY 1066 based on composition of molybdenum disulfide and graphite, coatings withstand high loads even at small rotation speeds, have high separating and anti-corrosive properties. Due to these solid-film coatings, service lifetime of the bearings extends.

Video

The product used in this solution is

Other applications of materials

MODENGY 1005

MODENGY 1066

RU

RU

EN

EN