MODENGY 1005 / 1066

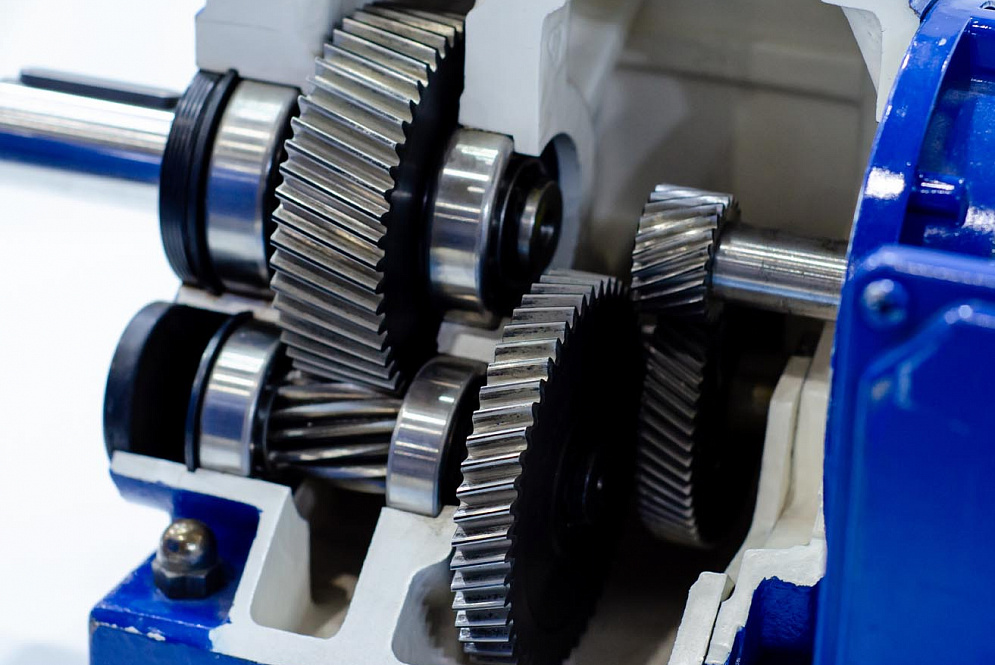

Reducer worm gears

Image source:

shutterstock.com

Because of heavy loads and high friction, the parts of the reducer worm gears – worms and quadrants – get worn prematurely.

To reduce friction, and to protect the elements against corrosion, MODENGY 1005 and MODENGY 1066 anti-friction solid-film coatings are used. They have high load-carrying capacity, wear resistance, operability in dusty environments, and long service lifetime.

These materials enable to create a friction unit that requires no maintenance since they perform as efficient replacement for greases that have been used to maintain the units before.

Video

The product used in this solution is

Other applications of materials

MODENGY 1005

MODENGY 1066

RU

RU

EN

EN