MODENGY 1005 / 1066

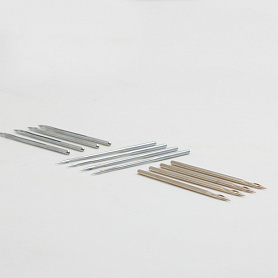

Reducers bearing rings

Image source:

shutterstock.com

Reducers bearing rings are operated under conditions of high contact pressures within a wide temperature range from -61 °C to +250 °С. Conventional lubricating materials are not effective enough in such units what leads to fast wear of the parts, and significant decrease of their service lifetime.

MODENGY 1005 and MODENGY 1066 coatings based on graphite and molybdenum disulfide form an anti-friction layer on the surface of the rings having high load carrying capacity. It preserves the elements against premature wear due to reducing friction coefficient, and enables to considerably extend service lifetime of the reducers bearing rings.

MODENGY 1005 and MODENGY 1066 coatings based on graphite and molybdenum disulfide form an anti-friction layer on the surface of the rings having high load carrying capacity. It preserves the elements against premature wear due to reducing friction coefficient, and enables to considerably extend service lifetime of the reducers bearing rings.

Video

The product used in this solution is

Other applications of materials

MODENGY 1005

MODENGY 1066

RU

RU

EN

EN