MODENGY 1002

Anti-friction solid-film coating based on molybdenum disulfide

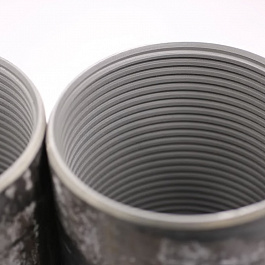

It is used in sliding guideways of the machine tools, flat springs, splined joints of the equipment's driving shafts

Package sizes:

MODENGY 1002 in action

Additional expendable materials

and equipment

- MODENGY Special Cleaner-Activator is intended to clean, degrease, activate surfaces

- MODENGY 1013 Special Solvent to rinse the equipment after the coating is applied, to remove uncured coating

- MODENGY M1-250 Spray gun - to apply MODENGY anti-friction solid-film coatings

Advantages

- Low friction coefficient

- High load-carrying ability

- There is no chalking (solid lubricant is not separated from the binder)

- Wide service temperature range

- Workability in dusty environment

- High adhesion

- It has properties of anti-emergency lubrication

- Effective protection against fretting-corrosion

- Resistance to water wash-off

- Anti-corrosive properties

- It prevents stick-slip motion

- Long service life (dependent on the unit construction – durable lubrication)

Specifications

- Colour: grey

- Service temperatures range: -210 … +320 °C

- Corrosion protection: > 160 hours (ISO 9227)

- Standard coating consumption: 80 g / m²

- Curing temperature / time: +20 °C / 120 min

Applying the coating by your own

Use to prepare and clean the surface. Only it guarantees good adhesion

Keep shaking the aerosol can with the coating for at least 3 minutes after you hear tapping of a little ball inside it

Spray the coating from the aerosol can onto the surface to be treated from the distance of 20 to 30 cm

Let the coating dry for at least 10 min. at room temperature until opacity appears (it’s the interim air-drying stage)

Apply the second layer of the coating over the dried previous one, if necessary

Let the coating dry for at least 120 minutes at room temperature (it’s the final air-drying stage)

It is used in the following typical units

Sliding bearings, sliding guideways, tooth gears, threaded connections, splined joints, and keyed connections, adjusting wedges, the other units with metal/metal friction pairs

RU

RU

EN

EN