A throttle valve, located between the air filter and inlet manifold, plays the role of a controller of supplying fuel-and-air mixture into the inner combustion engine.

It operates on the principle of an air valve, namely, when the throttle valve is open pressure in the system gets equal to the atmosphere pressure, and when it is closed, pressure reduces down to its maximum value, down to underpressure.

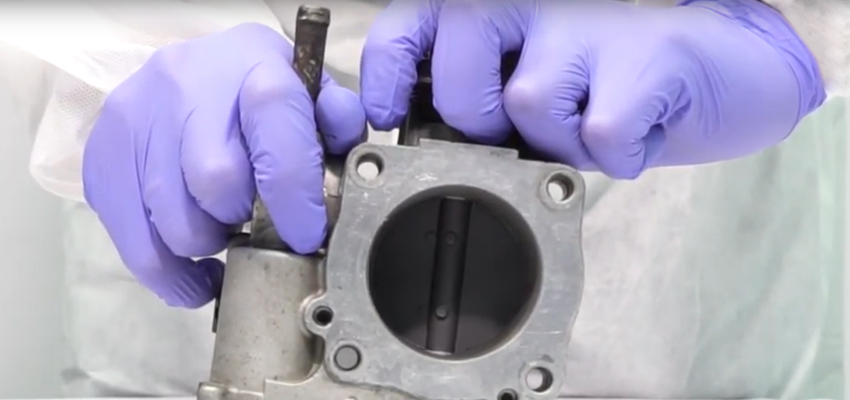

It natural that the throttle valve gets contaminated with the fuel combustion products during operating. If the engine is equipped with the exhaust gas recirculation system, the contaminating particles penetrate not from the side of the inlet manifold only but also from the air duct.

Due to existing axial play, the shutter rubs a groove in the body of the throttle in the course of time. Its depth can make down to 1 mm. The aluminum body of most shutters get worn. As a result, the fuel mixture gets depleted, idle revolutions get unstable and hard to be adjusted. Motion smoothness and dynamics of car acceleration get broken.

It is possible to minimize risk of arising troubles with the engine by treating the throttle valve with the anti-friction solid lubricating coating.

Applying the coating will enable to provide the following:

- Smooth motion of the shutter

- Increase of its sensitivity

- Prevention the mechanism against jamming

- Shutter tightness

- Minimal wear

The protective coatings are sometimes applied onto the throttle valve at the manufacturing plant. By appearance the treated surfaces look like the painted ones. They can get worn or damaged in the course of time if maintenance of the car is performed in non-qualified way (these coatings can be taken for carbon deposit by mistake, and are tried to be removed).

If the damaged coating is not restore in time, accuracy of shutter operation and its service lifetime will significantly reduce according to the reasons considered above.

MODENGY For ICE Parts Anti-Friction Solid-Film Coating will fit perfectly to be applied onto the throttle shutter and body.

The compound based on molybdenum disulfide is produced in the handy aerosol cans, and cures at room temperature which enables to use it without specific equipment.

MODENGY For ICE Parts coating is resistant to aggressive media exposure including fuels, so it retains its wholeness during the whole service lifetime of the shutter, and thus protecting it against corrosion and wear, preventing the mechanism against jamming, increasing its tightness and sensitivity.

This product is applied onto the surface after is has been cleaned mechanically and treated with MODENGY Special Cleaner-Activator, which provides the best possible coating adhesion to the base. For better efficiency several layers should be applied with 10-minute interval to let each layer to get dry.

Applying the coating by your own

Use to prepare and clean the surface. Only it guarantees good adhesion

Keep shaking the aerosol can with the coating for at least 3 minutes after you hear tapping of a little ball inside it

Spray the coating from the aerosol can onto the surface to be treated from the distance of 20 to 30 cm

Let the coating dry for at least 10 minutes at room temperature until opacity appears (it’s the interim air-drying stage)

Apply the second layer of the coating over the dried previous one, if necessary

Let the coating dry for at least 15 minutes at room temperature (it’s the final air-drying stage)

Assembly of the unit is possible in 12 hours after the coating has been applied and hold at room temperature. Curing can be accelerated by 20-minute heating the throttle valve in the kiln at +170 °С.

MODENGY FOR ICE PARTS coating is used to protect and improve performances not of the throttle valves only but of the other engine units as well such as piston skirts, valve rods, threaded connections, splined joints, camshaft and crankshaft bushings.

For more detailed information, and to get a consultation, please contact our experts.

Request information

RU

RU

EN

EN