MODENGY 1012

Anti-friction solid-film coating based on polytetrafluorethylene (PTFE)

It is used to reduce friction and eliminate squeak coming from the car interior plastic parts such as door panels, armrests, leather seat elements, dashboard shields, as well as in the threaded connections of the high-strength fastener, as an anti-adhesion agent to prevent sticking, and to improve sliding

Package sizes:

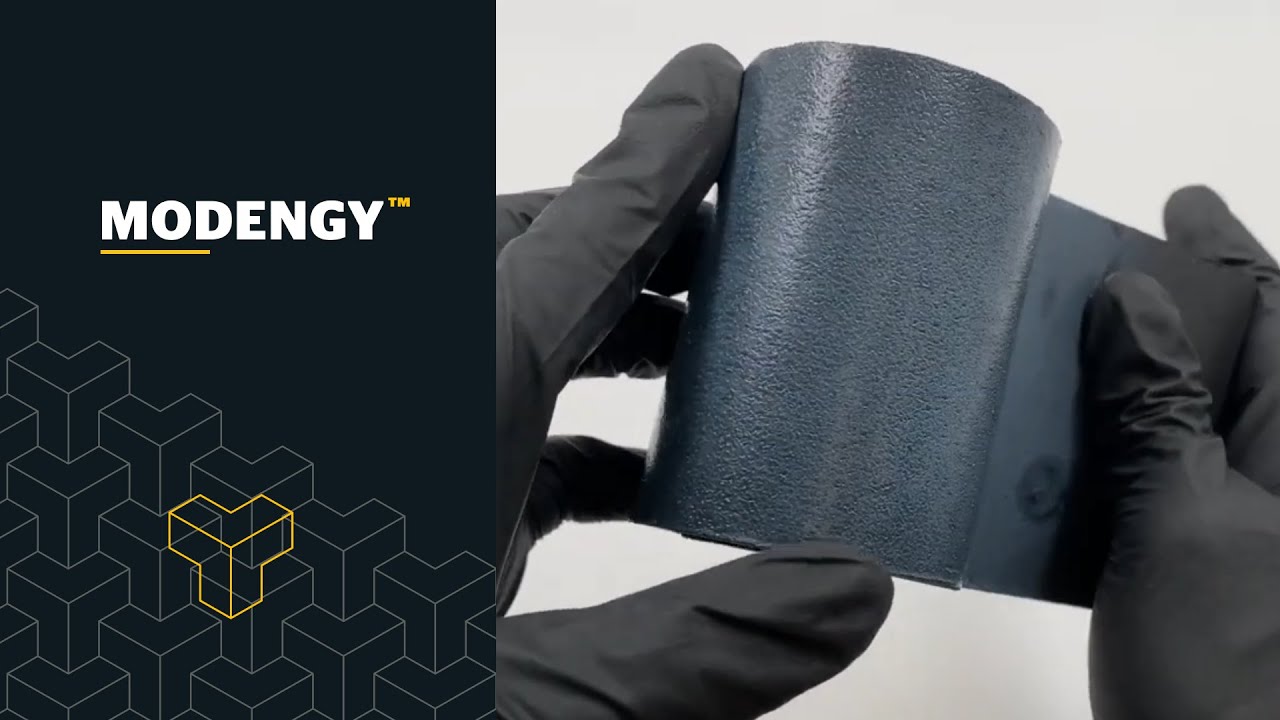

MODENGY 1012 in action

Additional expendable materials

and equipment

- MODENGY Special Cleaner-Activator is intended to clean, degrease, and activate surfaces

- MODENGY M1-250 Spray gun - to apply MODENGY anti-friction solid-film coatings

Advantages

- Low friction coefficient

- Fast cure at room temperature

- Wide service temperature range

- High adhesion

- Resistance to water wash-off

- Non-toxic after complete cure

- It speeds up parts assembly with robots

- It prevents stick-slip motion

- High anticorrosive properties

- It contains no organic solvents - it’s a water-based compound

- This translucent coating doesn’t spoil the car interior elements appearance

- Easy to apply with brush, sponge, or by spraying out

Specifications

- Colour: white translucent

- Service temperatures range: -50 … +130 °C

- Standard coating consumption: 50 g / m²

- Cure temperature / time: +20 °C / 30 min

It is used in the following typical units

Threaded connections, sliding guideways, sealing devices, the other units with metal/polymer, polymer/polymer, metal/metal friction pairs

Documents

Video

← Back to products

RU

RU

EN

EN