MODENGY 1032

Anti-friction solid-film coating based on polytetrafluorethylene (PTFE)

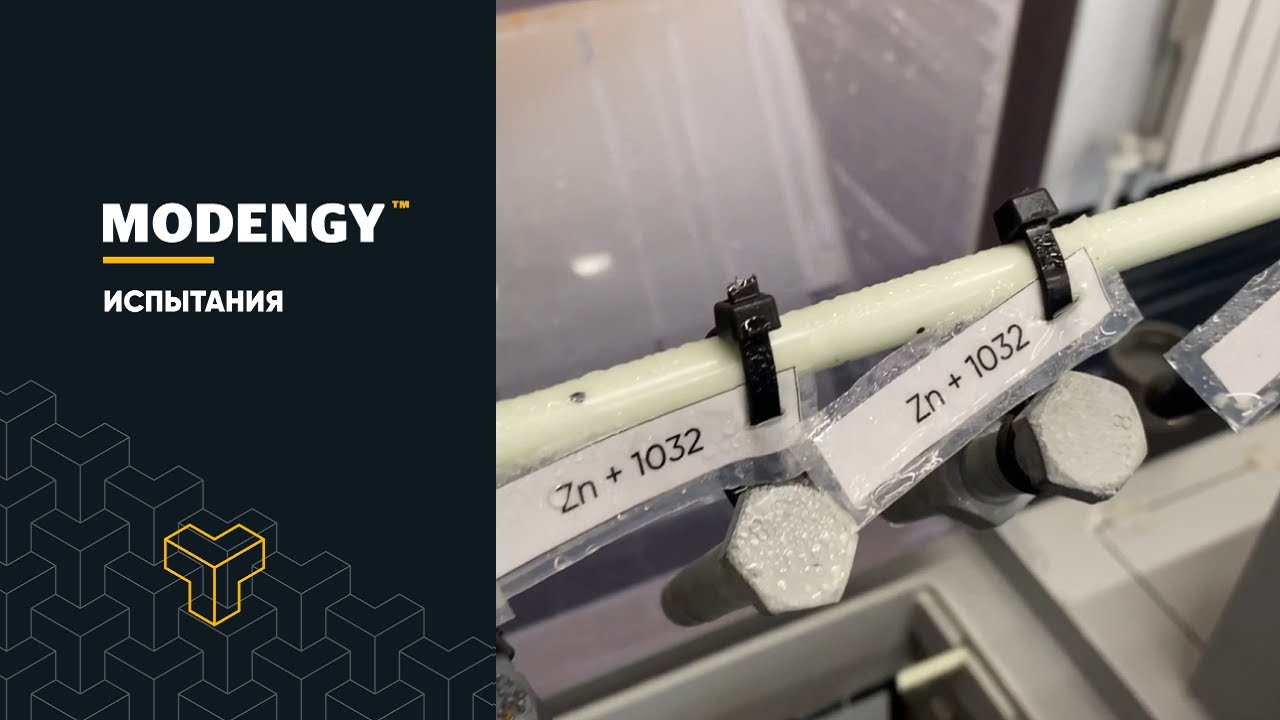

It is used on the threaded fasteners in complex with a basic zinc flake coating carrying out the tasks of additional protection, reduction and stabilization of screwing coefficient. It can be used in metal-to-metal, metal-to-plastic, metal-to-rubber sliding friction pairs.

Package sizes:

MODENGY 1032 in action

Additional expendable materials

and equipment

-

MODENGY Special Cleaner-Activator – to clean, degrease, and activate the surfaces

- MODENGY 1016 Special Solvent – to wash equipment after applying the coating, to remove non-cured coating,

to check coating cure completeness

-

MODENGY M1-250 spray gun – to apply MODENGY anti-friction solid-film coatings

Advantages

- Low and stable friction coefficient

- It prevents stick-slip motion

- High flexibility and spalling resistance

- Long service lifetime (depending on the unit structure – lifetime lubrication)

- Wide service temperature range (-100… +230 °С)

- Adaptive properties – ability to adapt following the mating part configuration

- Possibility to be applying by both methods of spraying out and dipping with centrifuging

- Resistance to sedimentation, that is to suspended particles deposition in the big technological reservoirs

Specifications

- Colour: silver

- Corrosion protection: > 900 hours (acc. to ISO 9227 standard)

- Polymerization temperature / time: +150 °С / 40 min. or +200 °С / 30 min.

- Service temperature range: -100… +230 °С

- Standard expense allowance of the coating: 77 g/m2

Video

← Back to products

RU

RU

EN

EN