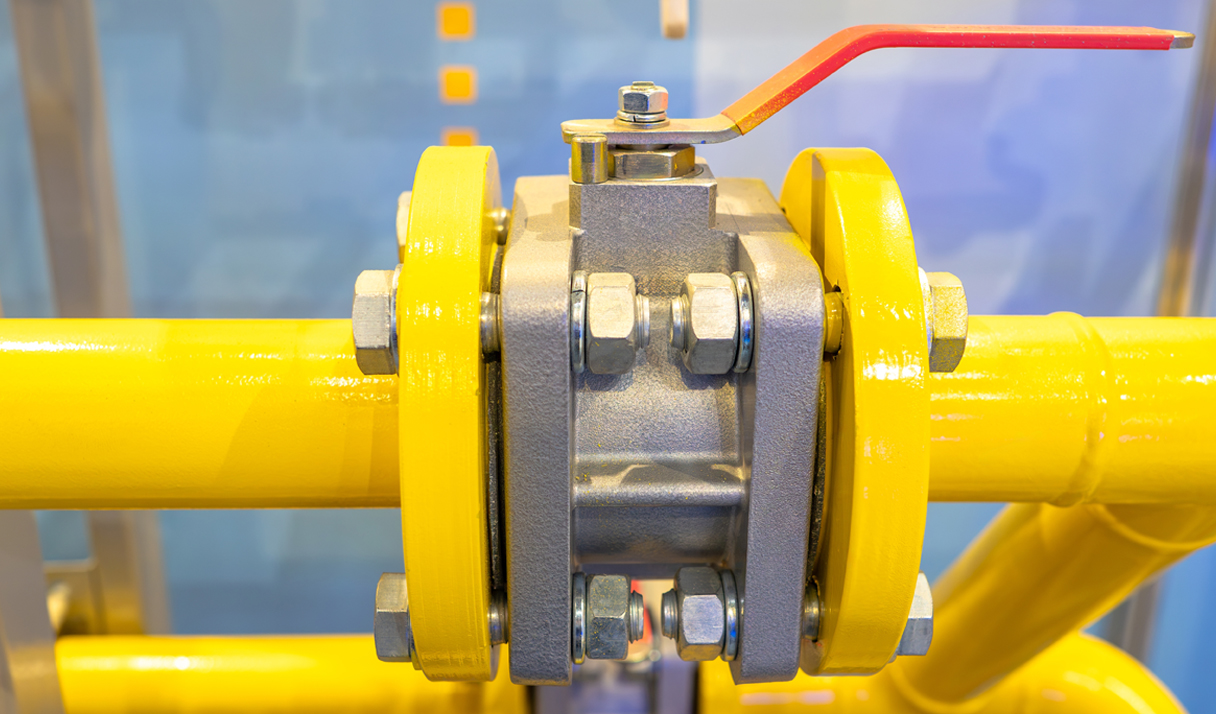

In process of operating, the parts are subjected to corrosion, deposits of salts are forming on them what leads to jamming the unit that gets hard to dismantle further.

To solve these issues, MODENGY 1014 anti-friction solid-film coating based on polytetrafluorethylene and molybdenum disulfide is applied onto the globe valve plugs.

It protects the parts against corrosion and aggressive media impact, reduces the force to turn the globe, extends service lifetime of the equipment.

MODENGY 1014 coating is applied out of spraying equipment onto the preliminary prepared parts surfaces, and requires heating to polymerize.

After curing, a thin dry lubricating layer that has high anticorrosive properties, wear resistance, and long service term is formed on the globe valves plugs, and in certain units, it provides lifetime lubrication.

Use of MODENGY 1014 anti-friction solid-film coating provides effective protection against corrosion and wear for the globe valves parts keep the units movable for a long while.

← Back to news

RU

RU

EN

EN