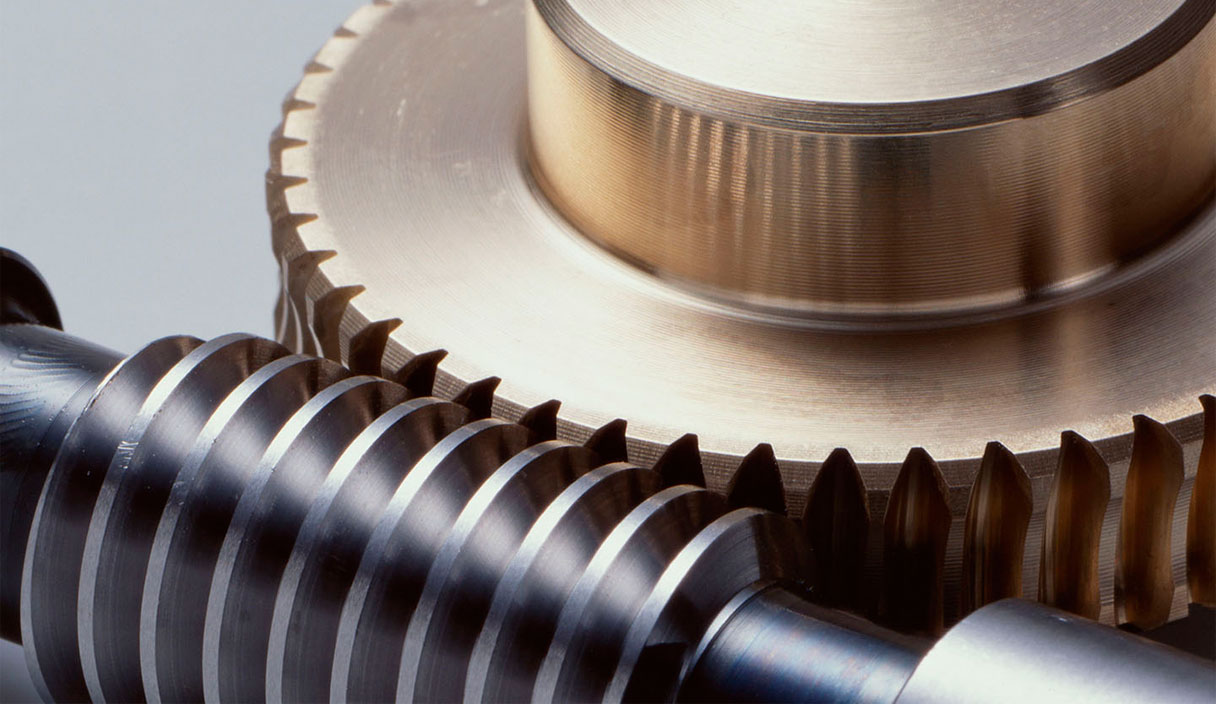

The worm gears manufacturers makes high requirements towards constructive materials combination (for example, tin bronze/alloyed steel), quality and cleanness of the part surfaces.

Neither less attention is paid to selection of lubricating materials to maintain such friction pairs in the course of operating process.

All these factors combined impact the efficiency and service lifetime of the worm reducers. At extremely low (down to -60 °С) or extremely high (over +200 °С) temperatures, significant contact pressures, and sliding speeds that the worm pairs undergo the conventional lubricants lose their effectiveness.

Having analyzed the worm gears operation conditions, the Modengy experts suggest the optimal solution to extend their service lifetime: MODENGY anti-friction solid-film coatings.

The test series have allowed revealing the most effective coating for worm pairs: MODENGY 1005 It provides a thin separating layer of solid lubrication in metal friction pairs, and in this way reduces wear of the gearing, and

increases its efficiency.

As a result of MODENGY 1005 coating application, many enterprises on worm reducers production have been able to abandon the expensive anti-friction materials for gear wheels, as well as to decrease the labour-output ratio in operations on part surfaces finishing treatment.

RU

RU

EN

EN