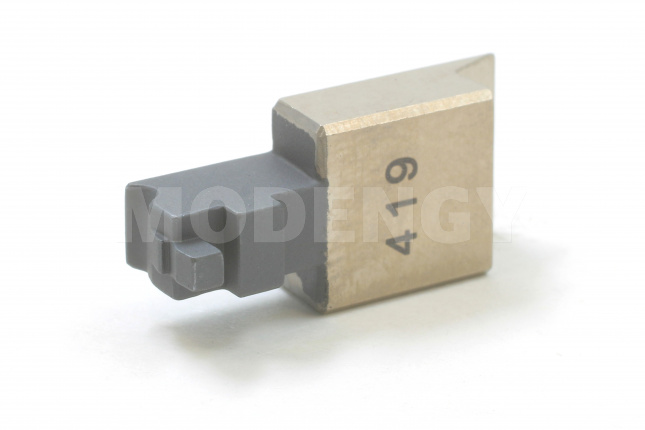

Anti-friction coating

Parts of the unit to produce bagged tea

Image source:

shutterstock.com

The paper labels are attached to the tea bags by means of metal brackets. They are set onto the bags at the specialty equipment that acts on the stapler principle

In order to guideways and side clamping elements don’t wear out, and keep on functioning, an anti-friction coating is applied onto their surfaces that provides dry and clean lubrication.

It not only extends service lifetime of the parts, and improves smoothness of their going, but also hinder tea dust to stick on, unlike the greases.

In order to guideways and side clamping elements don’t wear out, and keep on functioning, an anti-friction coating is applied onto their surfaces that provides dry and clean lubrication.

It not only extends service lifetime of the parts, and improves smoothness of their going, but also hinder tea dust to stick on, unlike the greases.

RU

RU

EN

EN