Absolute victory

over friction,

protection against

wear and corrosion

It stabilizes

friction

It protects against

wear and corrosion

The tasks that MODENGY coatings solve

Friction reduction and stabilization

in metal/metal pair

Providing longterm lubrication –

a unit requires no maintenance

Protection against scuffing and seizure

of the high-loaded friction unit

Replacement for conventional lubricating materials under highly

dusty conditions

High corrosion

protection level

Anti-emergency

lubrication

of tribotechnical and protective properties, extend equipment

service lifetime

MODENGY Coatings

Modengy, LLC, Bryansk, has developed a technology to reduce

friction and wear by means of special MODENGY anti-friction solid-film coatings.

Their composition includes highly dispersed particles of the solid lubricating materials, binders, solvents, and functional additives.

MODENGY coatings are applied onto the preliminary prepared part surfaces where they form a thin composite layer that provides efficient

dry lubrication, and corrosion protection for the items.

MODENGY Coatings’ Advantages

Low friction coefficient

(above 0.03 and higher)

High antiscuffing properties and load-carrying capacity

High anticorrosive properties

It prevents stick-slip motion

Resistance to washing off by water, and to chemically aggressive media

Wide service temperature range

Efficiency while being operated in dusty environments

It provides longterm lubrication

Small layer thickness (25 ± 5 µm) hardly changing the initial part dimensions

Non-toxic after complete cure

Operability in vacuum and under radiation conditions

It makes running-in, and part assembly process by robots easier

MODENGY coating use has become even easier

are available in aerosol package:

- Low friction coefficient

- Very high antiscuffing properties

- Fast curing within 15 min. at room temperature

- Low friction coefficient

- High anticorrosive properties (protection for 2.5 years)

Areas where MODENGY coating have been already used

on a series basis

Video

What else MODENGY 1001 and 1002

are unique by

They don’t require heating in kiln

Special balanced package with precisely adjusted spraying parameters

They don't oxidize

MODENGY 1001 and 1002

Coatings Applying Technology

Use MODENGYTM Special Cleaner-Activator to prepare and clean the surface. Only it guarantees good adhesion

Keep shaking the aerosol can with the coating for at least 3 minutes after you hear tapping of little balls inside it

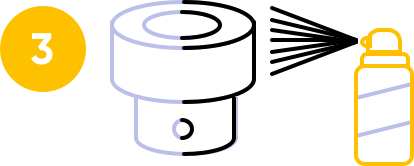

Spray the coating from the aerosol can onto the surface to be treated from the distance of 20 to 30 cm

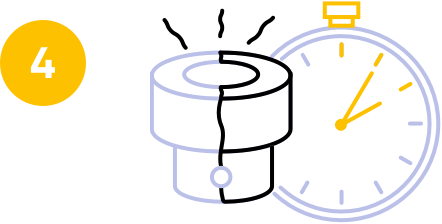

Let the coating dry for at least 10 minutes at room temperature until matt appears (it’s an interim air-drying stage)

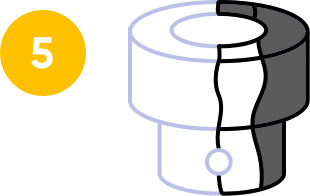

Apply the second layer of the coating over the dried first one if necessary

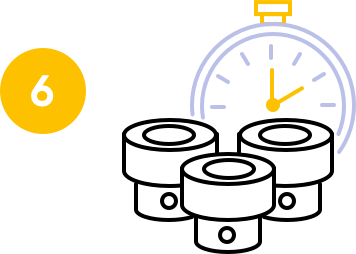

Let the coating dry completely at room temperature (MODENGY 1001 – 15 min.,

MODENGY 1002 – 120 min.)

By using aerosol package, you can apply MODENGY coatings fast and in a handy way virtually under any conditions.

Use only MODENGY Special Cleaner-Activator to prepare the surface!

The unique formula of the agent developed by our experts enables to clean and activate a surface perfectly prior applying the coating.

Only MODENGY Special

Cleaner-Activator

can provide the best coating adhesion!

The Special Cleaner-Activator enables to remove uncured coating easily (for instance, drips in case it was applied carelessly)

The part surface preparation is exactly what defined quality of the coating you will get, and its durability. The durable coating can be got only in case of flawless surface preparation

Warning! Only use of MODENGY Special Cleaner-Activator prior applying the coating guarantees the best result!

Learn more about Special Cleaner-Activator

RU

RU

EN

EN