Increase of the requirements on corrosion resistance of the materials in Energy, Oil-and-Gas sector, and Instrument-making involves use of the high-alloy steels and alloys.

Such materials are characterized by a number of advantages, but there are often a number of limitations, too, that impact on assembly and mounting of the threaded connections of stainless steel.

This article considers:

1. The ways of solving the issues of galling and jamming of the stainless fasteners during mounting

2. Some modern ways of increasing reliability during manufacture and assembly of the threaded connections.

Introduction

Up-to-date constructive materials enable to solve complex engineering tasks in different industries:

- Oil-and-Gas

- Energy

- Instrument-making

Corrosion-resistant metals and alloy are widely used at designing various equipment. The high-alloy steels containing chrome have high chemical and mechanical properties, and are characterized by corrosion resistance and belong to the stainless steels group. The most widespread are А2, А3, А4 austenitic steels. They are also wide known under the ‘nerzhaveyka’ (=stainless steel) Russian colloquial nickname.(Fig. 1)

Fig. 1 Stainless steel pipes

Let’s consider more details on the stainless threaded connections and fittings which are used for fastening at gas pipelines assembling, as well as for the cable inlets in the instrument-making sphere, energy equipment, at chemical components production.

Special features of the stainless threaded connections

In addition to the advantages given above, stainless steel has also a number of limitations related with chemical composition of the material. High content of the alloying elements decrease viscosity and the flow limit of the material, an oxide film fails to form on the surface of the part what results in friction increase within contact of the parts during the threaded connection assembly followed by heating and plastic deformation of the thread turns.

This effect is of the avalanche-like kind and leads to forming scuffing (Fig. 2) followed by thread galling. As the numerous test results reveal, it has been found that increasing of the tightening torque of the stainless fastener leads to the thread scuffing and makes the further dismantling impossible.

Fig. 2 Scuffing on the thread turn surface

Besides, the stainless joints and fittings are rather difficult to be mechanically treated what leads to rise in the costs on their production, and it’s hard enough to dismantle such joint in a mechanical way while thread is galled.

Anti-Friction Solid-Film Coatings is a new method to prevent thread galling

There are several ways to prevent excess friction in the threaded connection of stainless steel. All of them are based on solid lubrication technology when anti-friction material based on minerals, ‘soft’ metals or polymers is inserted into friction zone. The binding agent is used for the purpose of reliable fixing and retaining of the anti-friction filler.

1. Thread pastes application

Use of the thread pastes is relatively labourous and ineffective technology. So, the coatings where the binder safely retains the filler within the friction zone are more preferable now.

2. The coatings based on ‘soft’ metals (including copper plating, silver plating, etc.)

They have a complex apply technology and don’t provide required anti-friction performances. A reliable anti-friction layer to separate the interacting surfaces is impossible to provide at high screwing-off torques. Besides, the galvanic metal deposition technologies require specific conditions for storage and disposal of the wasted components.

On the ground of the numerous tests and practical experience, it has been proved the following: the efficient solution for the thread galling issue is applying anti-friction coatings based on minerals and polymers onto the threaded area of a fitting or a fastener.

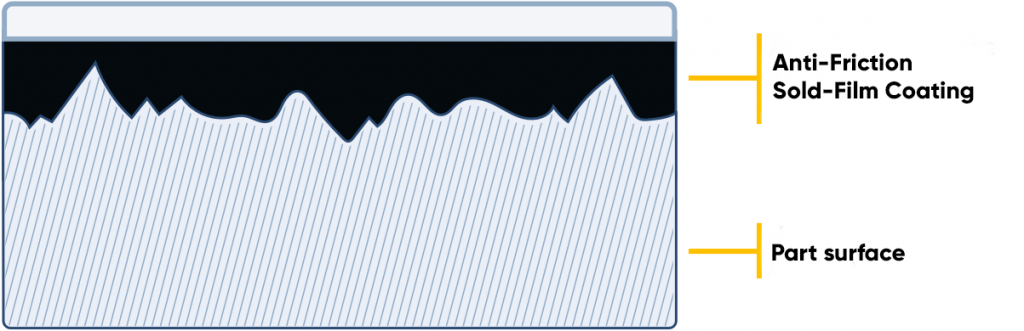

Application of MODENGY Anti-Friction Solid-Film Coatings (ASCs) is the most efficient and up-to-date solution. The structure of such coating on the surface of the threaded connection or a fitting item is given on the figure below.

Fig. 3 Anti-Friction Solid-Film Coatings structure

A thin film formed by the Anti-Friction Solid-Film Coating on the thread surface is a binder matrix firmly bonded to the base, while the very fine particles of the solid lubricating material fill in the cells of this matrix. The cavities of the surface microroughnesses are filled in, and as a result, its supporting surface extends, and its load-carrying ability grows

Fig. 4 Scheme of the contact interaction at friction without Anti-Friction Solid-Film Coating

Fig. 5 Scheme of the contact interaction at friction of the parts one of which was coated with Anti-Friction Solid-Film Coating

Due to its special structure, the coating has high compression strength and low shear strength. As a result, friction coefficient significantly reduces, and thus, the interacting surfaces are separated and get protection at high tightening torque values.

Coating advantages, and methods to apply them

MODENGY anti-friction coatings, a development of the Russian company, are produced on the basis of the patented technologies, and have been well proved in practice at many producers.

The main advantage of the Anti-Friction Solid-Film Coatings is their versatility, and possibility to be used on the threaded connections and fittings of various types, sizes, and diameters.

Other advantages:

- Stabilizing friction coefficient/twisting torque

- Resistance towards chemically aggressive media such as acids, alkalies, organic solvents, etc.

- Wide service temperatures range -180°С to +550°С

- Workability in vacuum and under radiation conditions

| Anti-Friction Solid-Film Coating Name | Colour | Service temperature range, °С | Curing temperature, °C | Chemical resistance | Application methods |

|---|---|---|---|---|---|

|

MODENGY 1004 |

Dark grey |

-190…+440 |

200 |

Excellent |

Spraying, dipping, centrifuging |

|

Black |

-70…+250 |

180 |

Good |

Spraying, centrifuging |

|

|

Grey |

-70…+250 |

180 |

Good |

Spraying, centrifuging |

|

|

Silver |

-75…+255 |

180 |

Excellent |

Spraying, centrifuging |

The ASС applying technology is environment friendly and doesn’t require significant investments into equipment. For the small-scale works, the technology of spraying the coating onto the thread surface can be used. The methods of dipping and centrifuging are used for applying in the industrial scale production. The coating layer thickness is adjusted within 3 to 20 µm range, and it enables to apply the coatings onto the threads of various types, and the threaded connections and fittings of different sizes.

You can submit a request for more detailed information about Anti-Friction Solid-Film Coatings technology via Modengy‘s website (modengy.ru). The Modengy specialists have successfully solved several dozens of the projects on protection of the threaded connections and fittings of stainless steel for cable inlets and air lines in the instrument-making (see Fig.6, 7), for steel in special video cameras in nuclear industry (see Fig.8), in the energy and oil-and-gas industries (see Fig.9).

Fig. 6 Cable inlets BEFORE applying Anti-Friction Solid-Film Coating

Fig. 7 Cable inlets AFTER treatment with Anti-Friction Solid-Film Coating

Fig. 8 Special video cameras in nuclear industry

Fig. 9 Cable inlets AFTER the Anti-Friction Solid-Film Coating has been applied

The following advantages have been obtained after applying MODENGY Anti-Friction Solid-Film Coating onto the threaded part of the items of stainless steel:

- Stabilized friction coefficient between the thread turns

- Protection against thread seizing and jamming

- Easy control over tightening torque

- Possibility of multiple adjustment of the joint (loosening-tightening)

Conclusion

MODENGY technology of anti-friction coatings applying during manufacturing and mounting of the threaded connections and fittings of stainless steel enable to prevent thread seizure and jamming, and to increase torsion torque. The mechanism of MODENGY technology is based on the solid lubrication principle, while use of the up-to-date binding components and solid lubricating material helps form a thin protective layer on the thread turns, and quickly introduce this technology into production of the various goods.

Application of MODENGY Anti-Friction Solid-Film Coating technology has allowed many Russian companies not only to follow the import substitution concepts but also obtain significant competitive advantages.

RU

RU

EN

EN