MODENGY 1014

Anti-friction solid-film coating based on polytetrafluorethylene (PTFE) and molybdenum disulfide

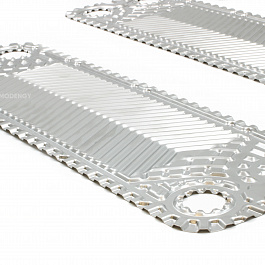

It is used in chemical pumps and pipeline valves; soldefing plates of the packaging equipment; the sliding friction units exposed to heating, dust, humidity, and chemically aggressive substances where oils and greases are not effective; in pneumatic cylinders, parts of the locks, hinges, automotive fastening elements in cars; in the units and mechanisms of the aerospace machinery; In the offshore oil platform fasteners; in the polymer production line calibrators

Package sizes:

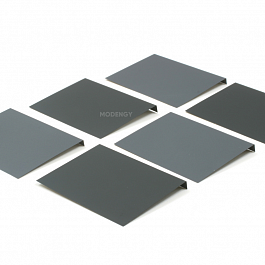

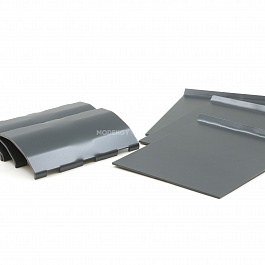

MODENGY 1014 in action

Additional expendable materials

and equipment

- MODENGY Special Cleaner-Activator is intended to clean, degrease, and activate surfaces

- MODENGY 1013 Special Solvent to rinse the equipment after the coating is applied, to remove uncured coating, to control completeness of coating polymerization

- MODENGY M1-250 Spray gun - to apply MODENGY anti-friction solid-film coatings

Advantages

- Low friction coefficient

- Chemical resistance

- Fast cure at room temperature

- Wide service temperature range

- Workability in the dust environment

- High adhesion

- Non-toxic after complete cure

- It prevents stick-slip motion

- Separating properties

- Longterm service life

- It speeds up parts assembly with robots

- High anticorrosive properties

Specifications

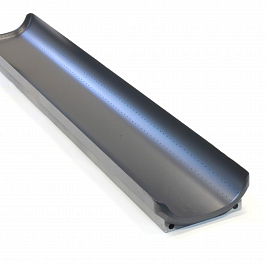

- Colour: grey

- Service temperatures range: -75 … +255 °С

- Corrosion protection: > 672 hour (ISO 9227)

- Standard coating consumption: 55 g / m²

- Cure temperature / time: +200 °C / 40 min

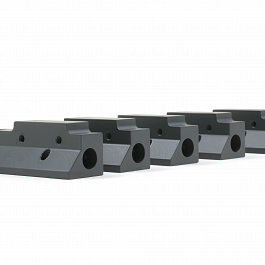

It is used in the following typical units

Sliding bearings, sliding guideways, threaded connections, the other units with metal/metal, metal/plastic, metal/rubber friction pairs

Documents

Video

← Back to products

RU

RU

EN

EN