Features of the Anti-Friction Solid-Film Coatings technology

The Anti-Friction Solid-Film Coatings (ASCs) implement a special technology which core is in creating a thincomposite film on the surfaces of parts. The film is a polymer matrix whose cells are filled with the ultrafine particles of the solid lubricating materials including molybdenum disulfide (MoS2), graphite, polytetrafluorethylene (PTFE), tungsten disulfide, metal oxides, and others.

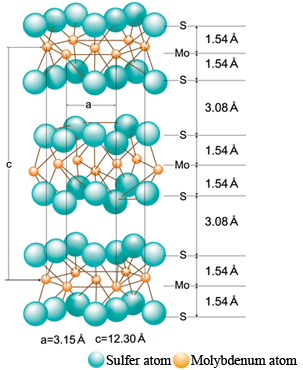

The mechanism of the Anti-Friction Solid-Film Coatings lubricating and protective actions can be explained on the example of the layeredcrystal structure of MoS2 molecule – one of the most popular components of MODENGY coatings.

In state of rest, the distance between the molybdenum atoms is extremely small, that's why, the links betweenthem are the strongest. The distance between the sulphur atoms, on the contrary, is great – in fact, they are located on the different angles of the crystal lattice (see Fig.1).

Fig. 1. Molybdenum disulfide molecule structure.

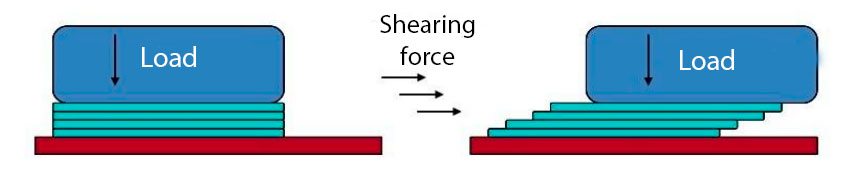

When shearing force appears, the ‘sandwich’ effect arises at which the crystal lattice layers of the different atomsslide relative to each other (see Fig.2). At the 25 µm coating thickness, there can be up to 100 and even more such layers moving along each other. It enables to achieve maximum reduction of the friction force between the contact surfaces, and thus, wear reduction.

Fig. 2 The solid lubrication technology. The ‘sandwich’ effect.

MODENGY 1001 coating advantages

MODENGY 1001 is an Anti-Friction Solid-Film Coating based on molybdenum disulfide, graphite, andinorganic binding substance. The solid lubricants give the coating the grey-and-black colour, and matt texture.

The given coating is used in the units with metal-to-metal friction pairs. Unlike the greases, oils, and otherconventional lubricating materials which have comparatively narrow service temperature range, and significant load limitations, MODENGY 1001 coating instead retains its functions even under extreme operation conditions.

Coating demonstrate the following properties and advantages:

- Wide service temperature range: -180°С to +440°С

- High load carrying capacity at high specific loads (at contact pressures up to 2,500 MPa)

- High extreme pressure properties

- Effective friction coefficient reduction

- Capacity to prevent stick-slip motion

- Operability in chemically aggressive media, under conditions of vacuum, and radiation

- Stabilization of the tightening moment

- Efficiency in dusty environments due to the ‘dry’ lubrication technology

- Fast polymerization at room temperature (within 15 minutes)

- No evaporation and oxidation of the compound even after longterm downtime of the unit

MODENGY 1001 is available in a number of package sizes including plastic capsules, cans, pails, and aerosol cans (see Fig.3).

Fig.3. MODENGY 1001 coating

MODENGY 1001 coating applying technology

Prior to apply MODENGY 1001 special MODENGY Cleaner-Activator should be used.

It removes a shielding film off the parts, cleans, degreases, and activates the surfaces to provide better coatingadhesion to the substrate. If some cured residues of the coating need removing, use MODENGY 1013 special solvent.

Shake an aerosol can with MODENGY 1001 coating for at least 3 minutes until you can hear tapping of a littleball inside it. Then spray out the compound onto the surface to be treated from the distance of 20 to 30 cm.

The coating from the cans are applied by the methods of painting – by centrifuging or from the sprayingequipment. Use special MODENGY paint spray gun to spray out.

The stage of in-between drying makes about 10 minutes – for this period, the treated item gets matt onappearance and dry on touch. Then if necessary apply another layer of the compound which will get completely dry just in 15 minutes at room temperature.

Examples of MODENGY 1001 coating applications

MODENGY 1001 Anti-Friction Solid-Film Coating is used in the various units of industrial equipment. Thecertain examples and the tasks that are solved by the coating in these or those cases are listed in Table 1.

The results of the MODENGY 1001 application are visually presented on figures 5 to 7 down below.

Fig. 5 Screw pair of the compressor equipment

Fig. 6 Fittings made of stainless steel

Fig. 7 Sliding guideways

Table 1 Examples of MODENGY 1001 coating applications, and the tasks it solves

| Unit | The tasks it performs |

|---|---|

| Screw pair of the compressor equipment |

|

| Lead screws of the lathe machines |

|

| Fittings made of stainless steel |

|

| Locking valves at the thermal power-stations |

|

| Worm gear and spline shaft of the lifting equipment |

|

| Blading unit locks of the turbine |

|

| Sliding guideways of machine calipers |

|

Conclusion on application of the coating

MODENGY 1001, that realizes the solid lubrication technology, provides high, quality operation results of the units and assemblies.

The coating creates a composite layer with excellent protective and anti-scuffling properties on the componentsurfaces, retains high load carrying capacity even at the extreme specific loads, eliminates unexpected failures in the used units.

Due to its aerosol package, it is easy to apply this compound, it requires no additional technological equipment and extra costs.

Since evaporation and oxidation are absent, MODENGY 1001 coating remains efficient even after longtermdowntime of the unit, or at operating in the idle mode.

The small layer thickness (10 to 20 µm) impacts little to the initial accuracy of the item dimensions.

MODENGY 1001 provides lubrication and protection to the contact surfaces for the whole service lifetime of theunits, that is serves as resource lubrication.

For more detailed information, and to get a consultation, please contact our experts.

Request information

RU

RU

EN

EN