Introduction

At the moment, the engineers actively use the achievements of the modern tribotechniques in their eager desire to create more and more durable, energy efficient, and compact machines.

Operation properties of the friction units are substantially defined by their parts’ surface quality. The Surface Engineering, a relatively new direction, is searching for the ways of solving the applied problems regarding improving the operation properties of the friction units by surface quality control of their parts.

As Mr. Igor V. Kragelsky, an outstanding scientist chemist, demonstrated in due time, one of the effective way to reduce friction and wear is to create thin films with low shear resistance on the surface. This it the way to provide the shear resistance gradient, to reduce friction coefficient, and wear, due to localization of the shear deformation in the thin surface layer.

Extensive research is being held in the field of the coatings of the tribological purpose now. The achievements and innovations in the field of such developments from Modengy, a young Russian company, are presented in this article.

What are Anti-Friction Solid-Film Coatings (ASCs)?

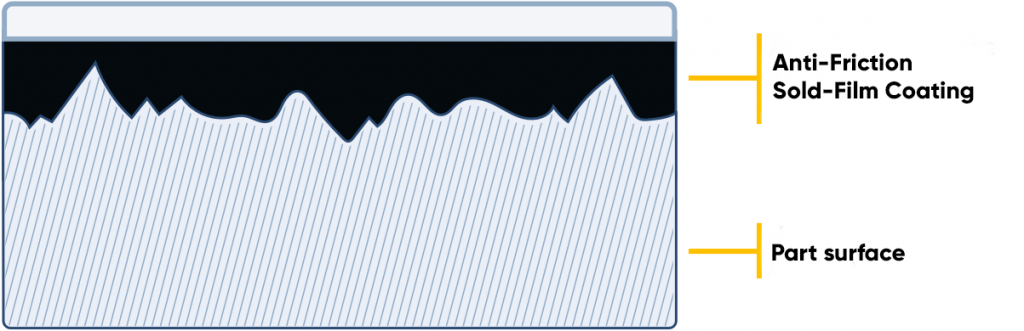

The Anti-Friction Solid-Film Coatings (ASC) technology enables to form a thin 5 to 20 µm thick composite layer on the part surface. This layer is a polymer matrix firmly bonded to the base, while its cells are filled with the ultrafine particles of the solid lubricating substance.

The coating has high compression strength and low shear strength. As a result, the dry friction coefficient reaches the values of a few hundredths at the contact pressures which are commensurable with the flow limit of the material of the base.

Figure 1 – MODENGY coating scheme

The structure of Anti-Friction Solid-Film Coatings at an increase of 500x (Figure 2).

Figure 2 – the structure of Anti-Friction Solid-Film Coatings

Modengy coatings. Formula and application

Modengy company was created by a group of young scientists and practical engineers, the graduates of the Bryansk State Technical University qualified in the Tribotechnics speciality, with involving the investments of the leading lubricating companies. Due to their efforts, an Anti-Friction Solid-Film Coating line, aimed to solving the most acute challenges related with friction and wear in the machine building industry, was developed.

More than 16 kinds of the coatings, in whose formulas the binding resins and solid lubricating materials of various chemical nature and structure are used, are available now. A brief review of the coatings composition formulas is given in the table below. The binding resins and solid lubricants can combine in various combinations, and at the same time demonstrate synergetic interaction.

Table 1. Basic functional components of MODENGY coatings

| Binding substance | Solid lubricant |

|---|---|

|

Modified epoxy resin Polyamide imide resin Phenol formaldehyde resin Modified styrene resin Polyurethane Acrylic resin Polybutyl titanate Organic silicone resin |

Molybdenum disulfide Polarized graphite Polytetrafluorethylene Tungsten disulfide Boron nitride Calcium and barium fluoride Zinc sulfide |

The developed coatings have passed laboratory testing according to the international standards stabled in the field in question (figure 3). Many of them are already successfully used on the batch items including the pipeline fittings.

Figure 3. Appearance of ACS on the outer cylindrical surface of test specimens on a roller friction machine

Principal advantages of the Anti-Friction Solid-Film Coatings technology from Modengy:

- High antiscuff properties and load-carrying ability up to 2,500 MPa, acc. to ASTM

- Dry lubrication is efficient in the dusty-laden environments

- Low friction coefficient down to 0.03, acc. to ASTM D2714

- Wide service temperature range -180°С to +600°С

- Resistance towards chemically aggressive media such as acids, alkalies, organic solvents, etc.

- Corrosion protection up to 1,000 hours in salt mist, acc. to ISO R 1456

- Workability in vacuum and under radiation conditions

- Typical coating thickness on the part surface is 5 to 20 µm, and it hardly influences the size initial accuracy

- Wear resistance is up to 400,000 cycles, acc. to ASTM D2714

Application of Anti-Friction Solid-Film Coatings technology allows to completely abandon lubricating liquids and greases by creating a friction unit that needs no maintenance. The coatings are to be applied just once, and they keep operating during the entire service life term of the item providing necessary surface lubrication and protection.

The Anti-Friction Solid-Film Coatings are efficient under extreme operation conditions such as at high contact pressures, impact of the chemically aggressive and corrosively active environments. In a number of cases, use of these coatings enables to avoid using the costly steels and alloys. Low friction of the coatings makes it possible to replace rolling friction units by the sliding friction units through optimization of the item weight and dimensions.

Modengy specialists select the optimal coating type based on the customer’s technical requirements taking into account specific features of the task to be solves. And for the purpose of providing the service of applying the coatings onto the parts, the experimental-industrial production has been established in Bryansk including the following steps of the full technological cycle:

- Quality assess of the part surface under the coating

- Surface preparation by chemical and mechanical methods

- Applying the coating by the method that takes into account part configuration and size

- Quality control according to adhesion, thickness, cure fullness, and abrasion resistance

Many specialists on armature engineering, and pump manufacturers already on continuing basis place their orders for the service of covering the parts of the friction units of the pipeline fittings including lead-screws, sliding valves, wedges and seats, sliding bearings of the pipeline valves, plugs and elements of rotating saddles of the ball taps, threaded fasteners, rack-gearings and pneumatic cylinders of the driving gears, rods and gates of the valves, sliding bearings, thrust bearings of the electric centrifugal oil pumps, and other parts (figure 5).

Figure 5. Examples of successful solving the engineering tasks with Modengy Anti-Friction Solid-Film Coatings

Conclusion

The lubricating material is an integral constructive element of a friction unit which significantly impact on all its operating properties. In present conditions, the conventional liquid lubricants and greases meet no longer ever increasing requirements regarding operation conditions. Modengy Anti-Friction Solid-Film Coatings technology provides the surfaces with necessary set of tribotechnical and protective properties.

Use of the technology enables to control friction effectively, and thus, to extend service life and energy efficiency of the machinery. Modengy engineers have already managed to solve a number of acute issues in armature engineering related to seizure, scuffing formation, stick-slip motion, and corrosion. For further information and getting consultation on your specific task solving, please contact Modengy company.

RU

RU

EN

EN