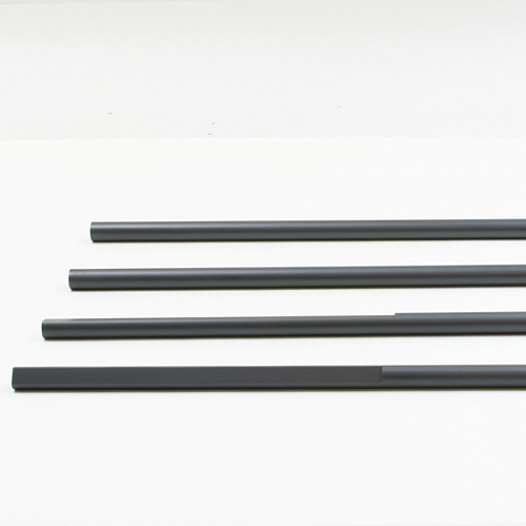

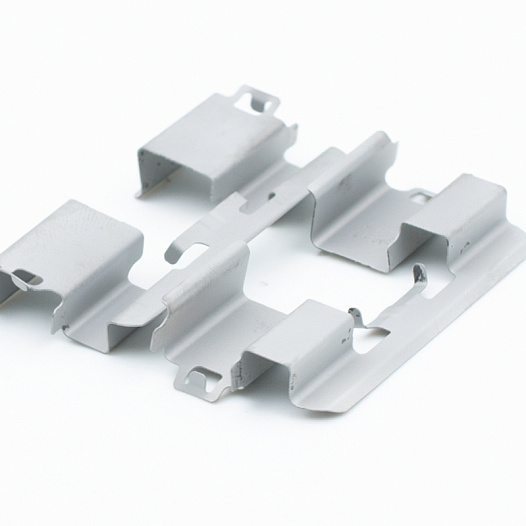

Edge-soldering elements

Edge-soldering elements

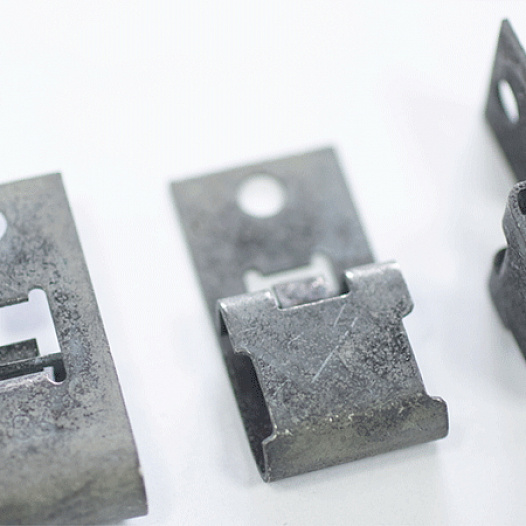

Before

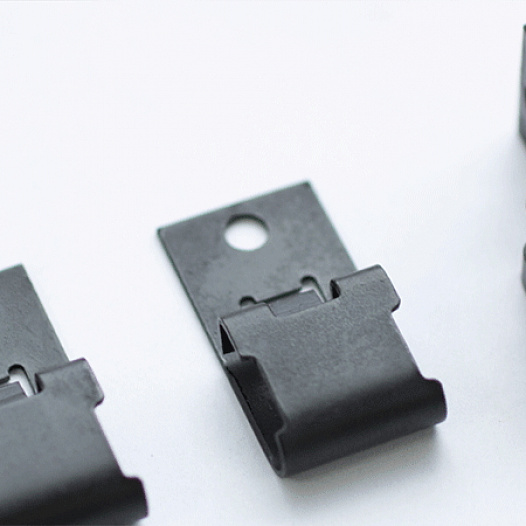

After

MODENGY 1007 coating is applied onto the operating surfaces of aluminum edge-solderers that are used to pack the products into polyethylene film. Due to its high anti-adhesive properties, the coating hinder the heated polymer from sticking to the edge-soldering elements.

Learn more about this solution

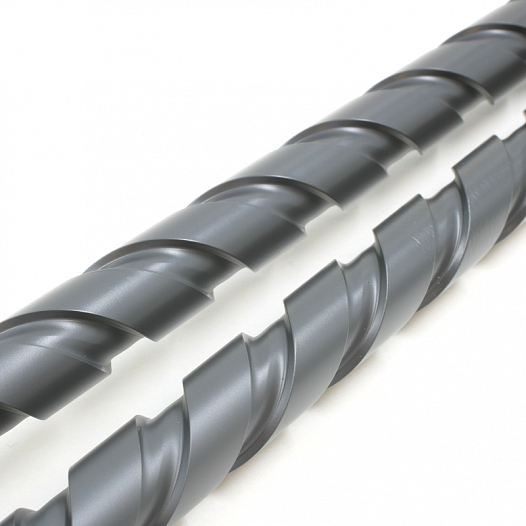

Lead screws of locking-and-regulating valves

Lead screws of locking-and-regulating valves

Before

After

This coating provides longterm dry lubrication of the lead screws, attract no small particles from the environment into the unit. Also, MODENGY 1014 effectively protects the parts against corrosion, prevents scuffing forming on the thread.

Learn more about this solution

Medical equipment side guides

Medical equipment side guides

Before

After

In order to improve glass containers sliding along the medical equipment side guides, MODENGY 1009 anti-friction coating based on polytetrafluorethylene is applied.

Learn more about this solution

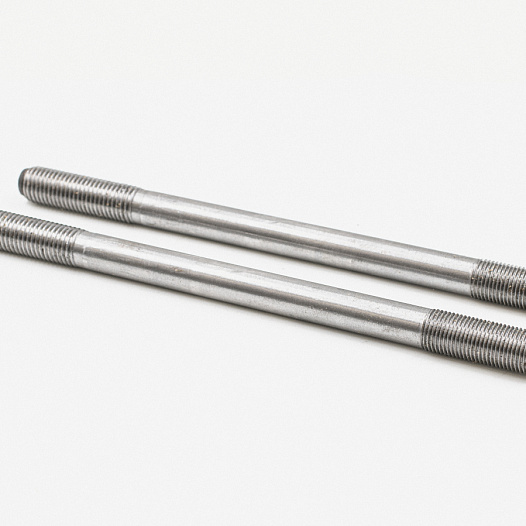

Exhaust manifolds studs

Exhaust manifolds studs

Before

After

MODENGY 1001 anti-friction solid-film coating enables to prevent engines exhaust manifolds studs from sticking, and to provide their easy dismantling.

Learn more about this solution

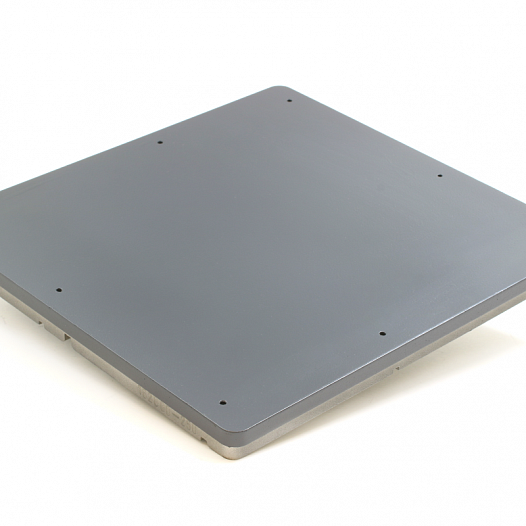

Calibrators' plates to produce polycarbonate

Calibrators' plates to produce polycarbonate

Before

After

MODENGY 1006 coating is successfully used on the calibrators' plates of the machine tools on producing honeycomb polycarbonate. A thin layer of this coating improves sliding of the sheets of the items along the plates preventing them from stick-slip motion.

Learn more about this solution

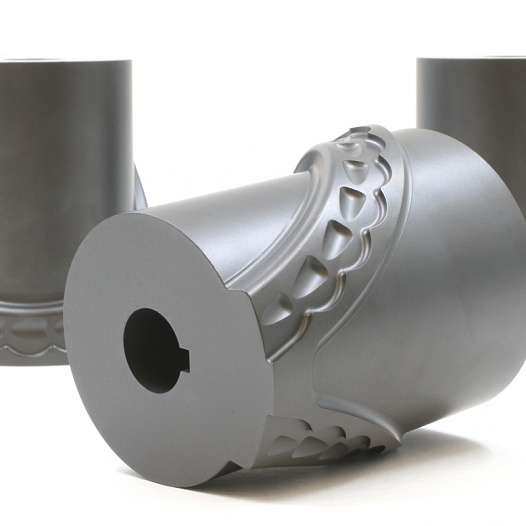

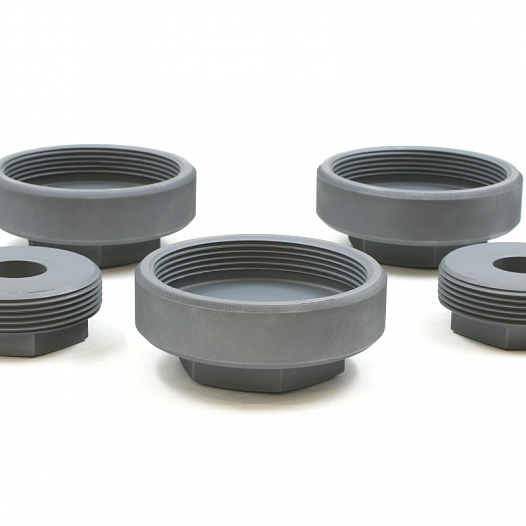

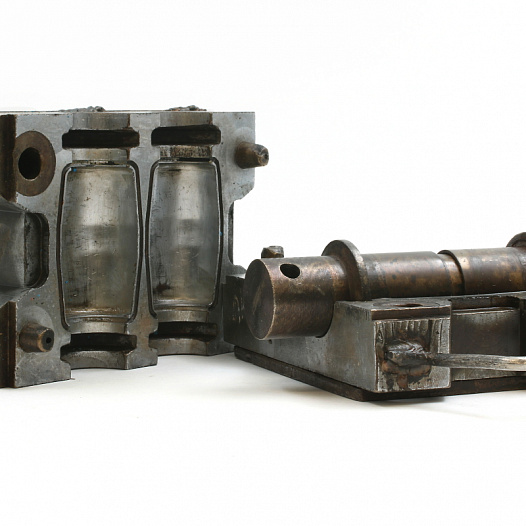

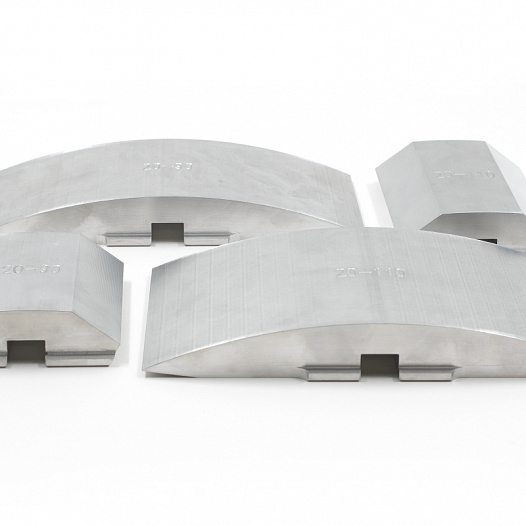

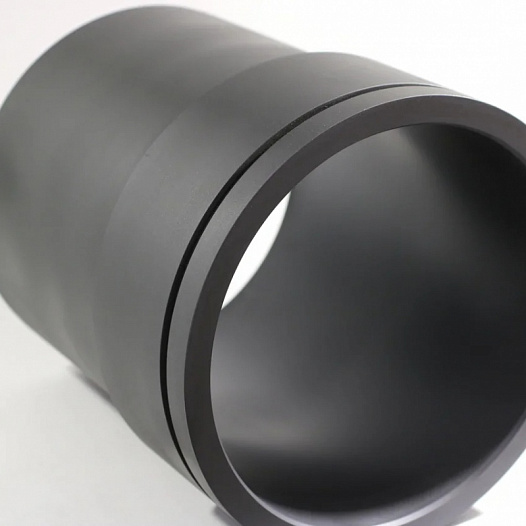

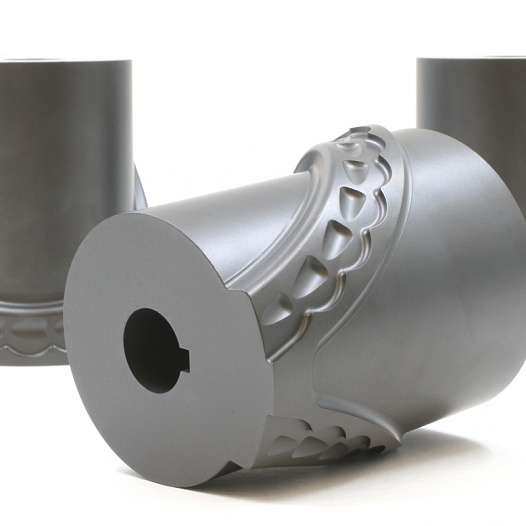

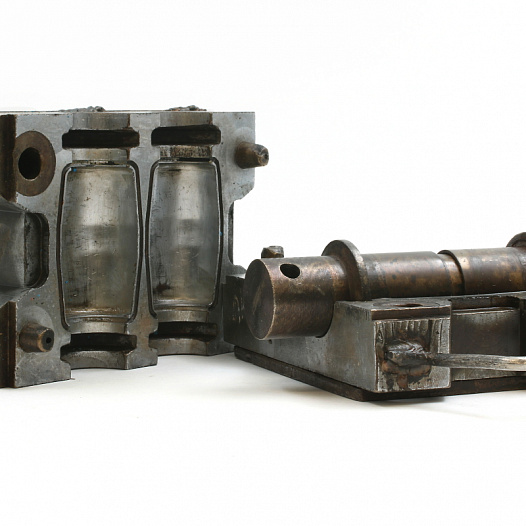

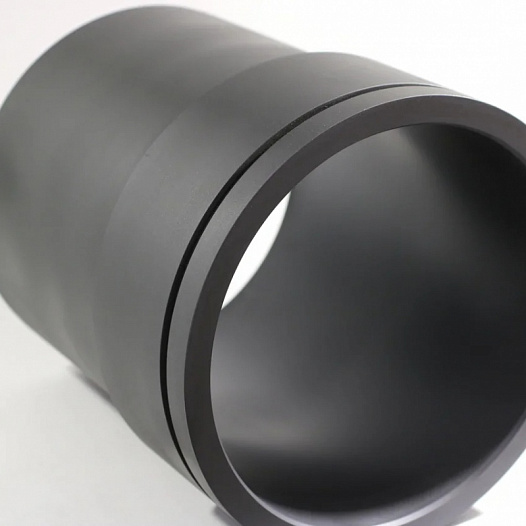

Molding gauges for low pressure polyethylene (LPP) pipes

Molding gauges for low pressure polyethylene (LPP) pipes

Before

After

To provide high quality of producing LPP pipes, MODENGY 1007 coating is applied onto the working surfaces of the molding gauges. Due to using it, heated polymer sticking to the forming tool is prevented, high quality of outer surface of the pipes is provided. Besides, a smoothy layer of the coating reduces friction of the surfaces, and wear of the molding gauges, prevents increase of the finished items diameter.

Learn more about this solution

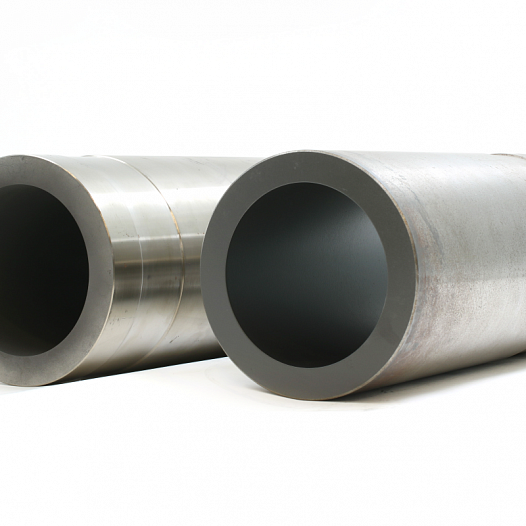

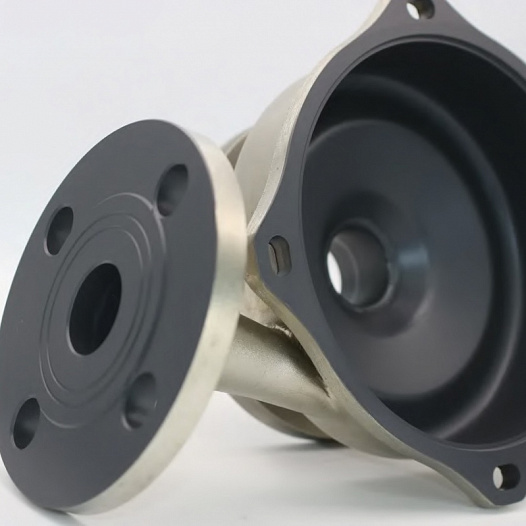

Plunger pair pistons

Plunger pair pistons

Before

After

MODENGY 1006 is applied onto plunger pairs pistons surfaces to protect them against scuffing, and to reduce wear of the units operating in the inert gas medium.

Learn more about this solution

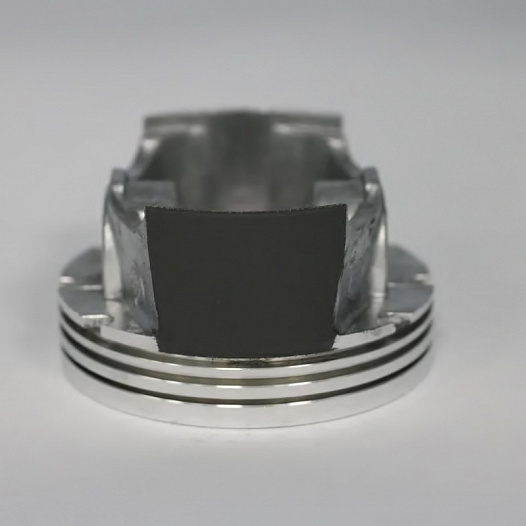

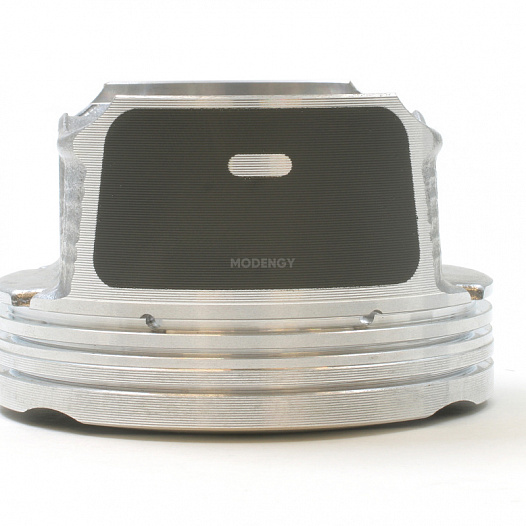

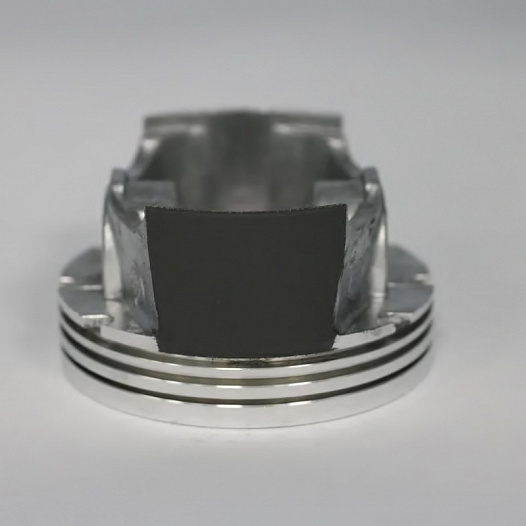

Car and motorcycle engine pistons

Car and motorcycle engine pistons

Before

After

MODENGY 1007 coating is applied onto the piston skirts by the screen printing method at industrial production of the engine parts.

It enables to make running-in easier, and to reduce wear of the pistons within the 'oil starving' period. As a result, engine reliability and operation term improve.

Learn more about this solution

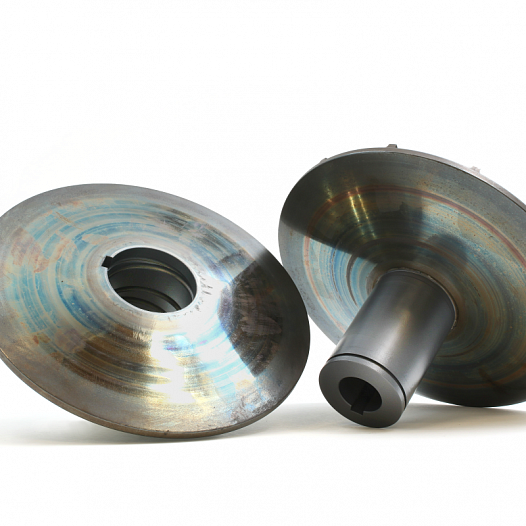

Bearings and thrusts of energy equipment

Bearings and thrusts of energy equipment

Before

After

MODENGY 1006 coating based on molybdenum disulfide and graphite is used to extend service lifetime of the energy equipment parts operating under extreme conditions.

It reduces friction and wear of the titanic bearings, and steel thrusts, provides trouble-free operating of the important units.

Learn more about this solution

Gas appliances sensors cases

Gas appliances sensors cases

Before

After

MODENGY 1014 anti-friction solid-film coating is applied onto the case surfaces that are in direct contact with gas. It effectively protects the parts against chemically aggressive substances impact including hydrogen sulfide, as well as has high anti-corrosive properties.

Learn more about this solution

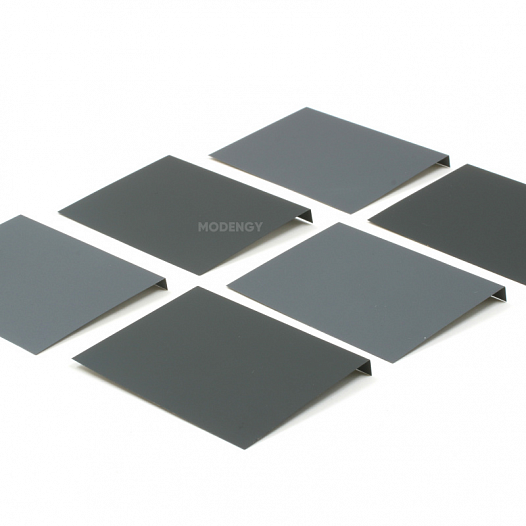

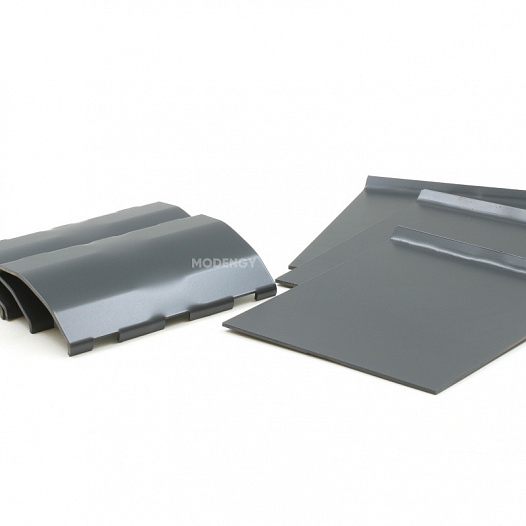

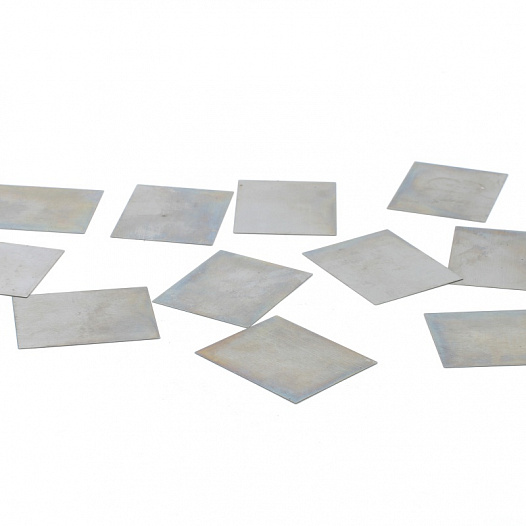

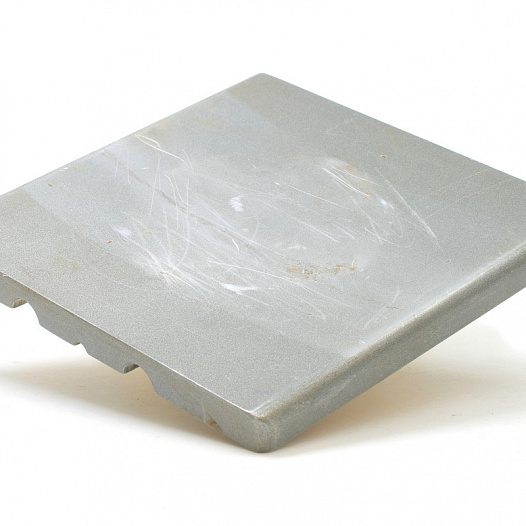

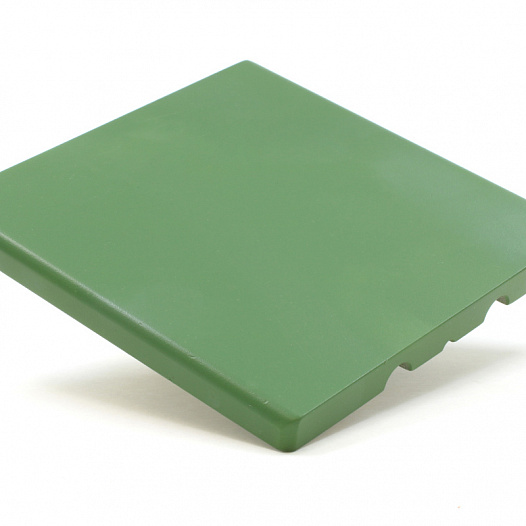

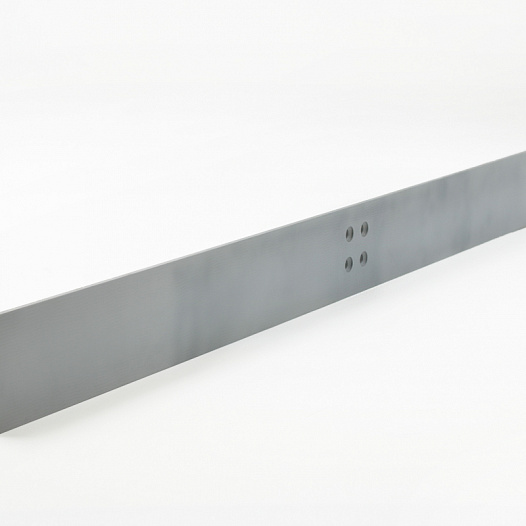

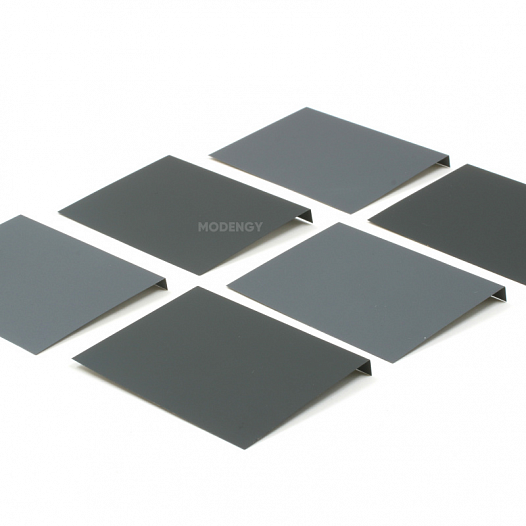

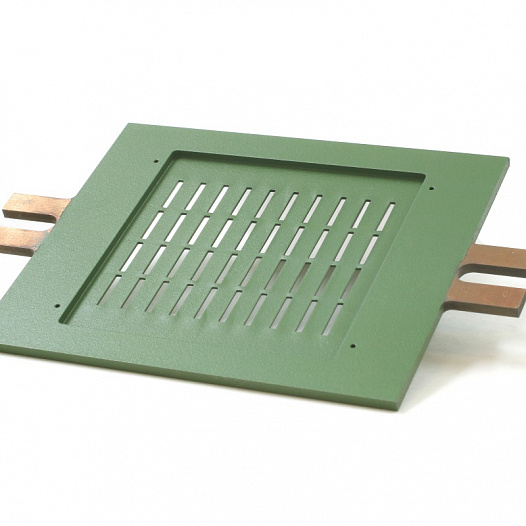

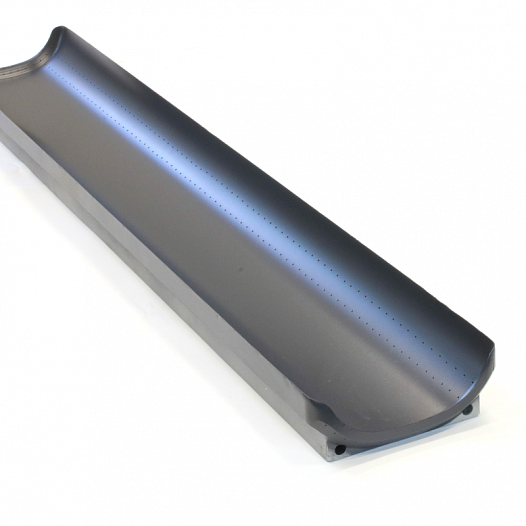

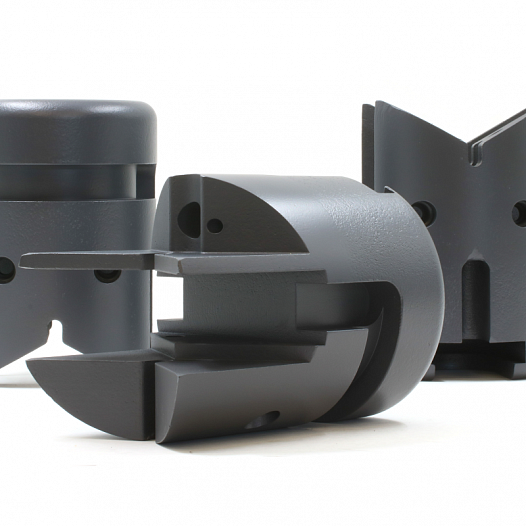

Edge-soldering plates

Edge-soldering plates

Before

After

MODENGY 1007 anti-adhesive coating creates a steady anti-burning layer on the plates surfaces that withstands high temperatures up to +350 ℃.

Learn more about this solution

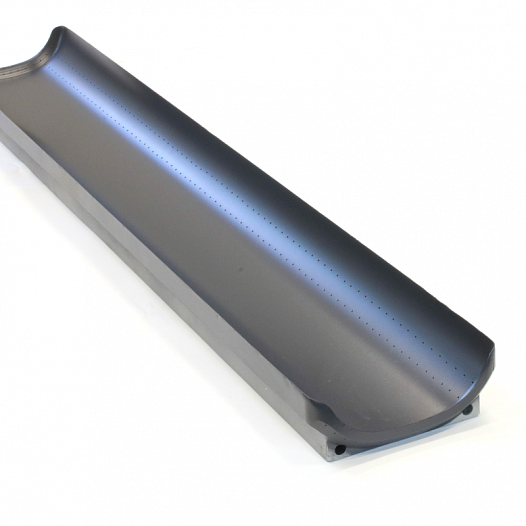

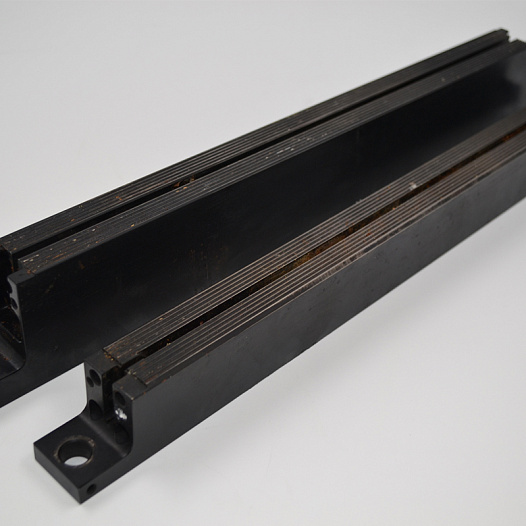

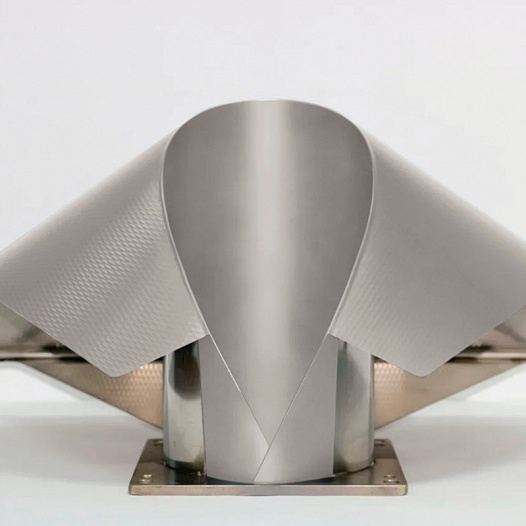

Radial leaf-type gas-dynamic bearings

Radial leaf-type gas-dynamic bearings

Before

After

They form a thin lubricating layer on the surfaces that reduces friction and wear, provides fast forming of an air wedge while he turbines are moving to the operating mode.

Learn more about this solution

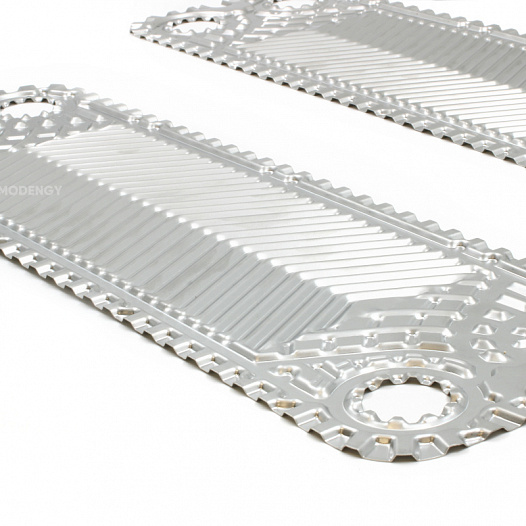

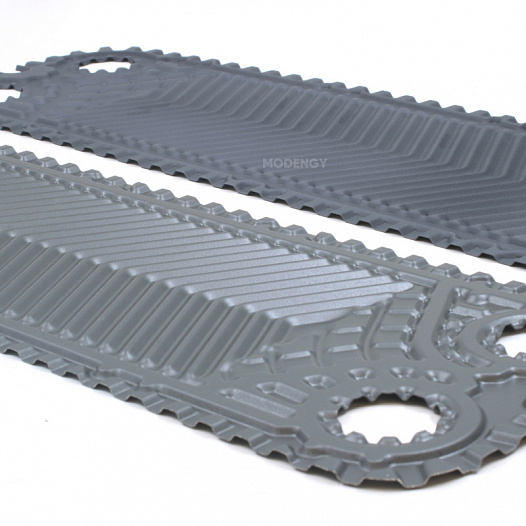

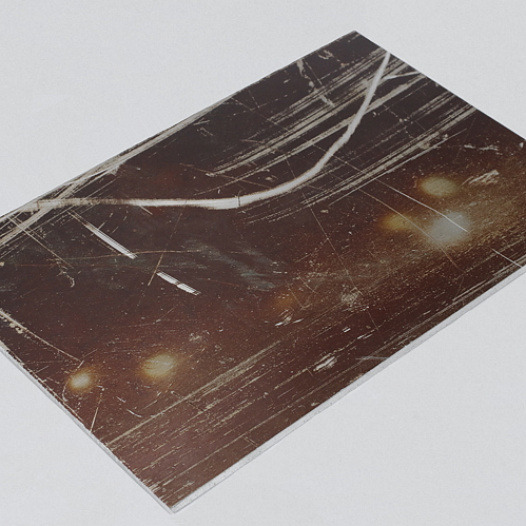

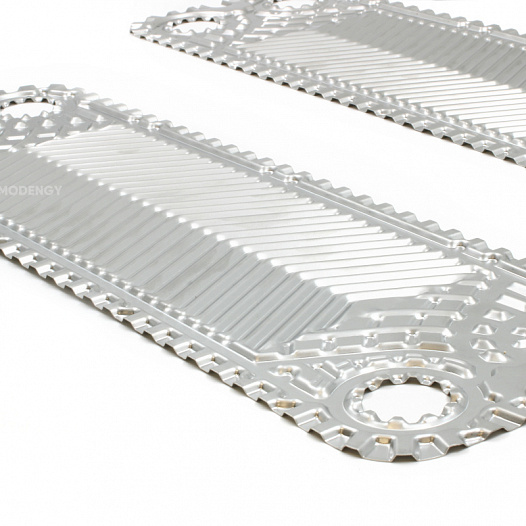

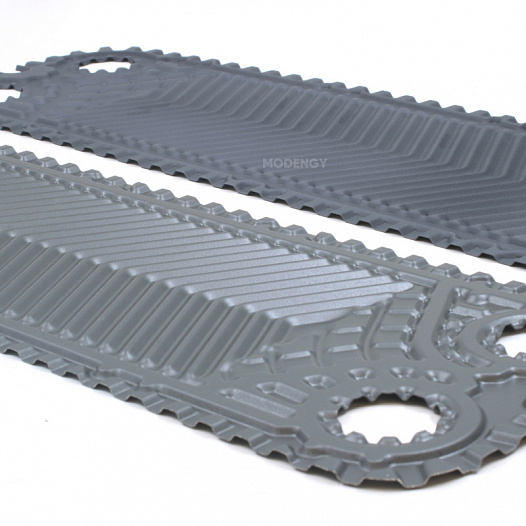

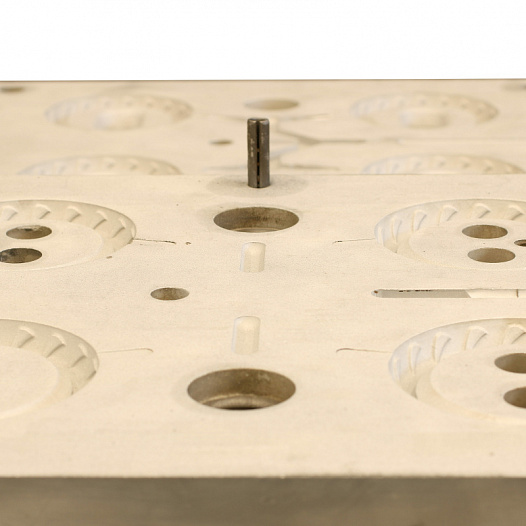

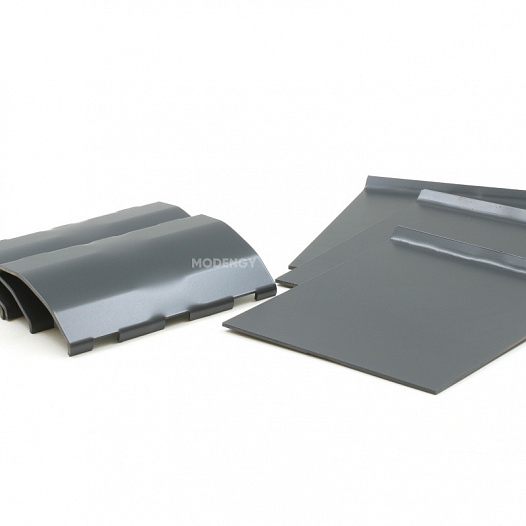

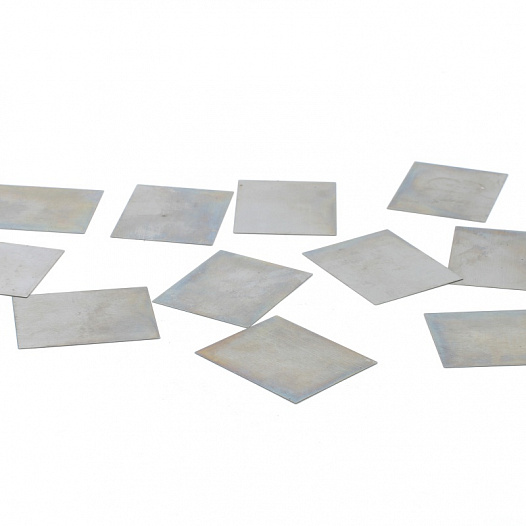

Heat exchangers plates

Heat exchangers plates

Before

After

After a long while of heat exchangers running, on the areas contacting with sulfuric acid, chemical corrosion, and deposits appear which inhibit regular media circulation, and heat exchange.

Learn more about this solution

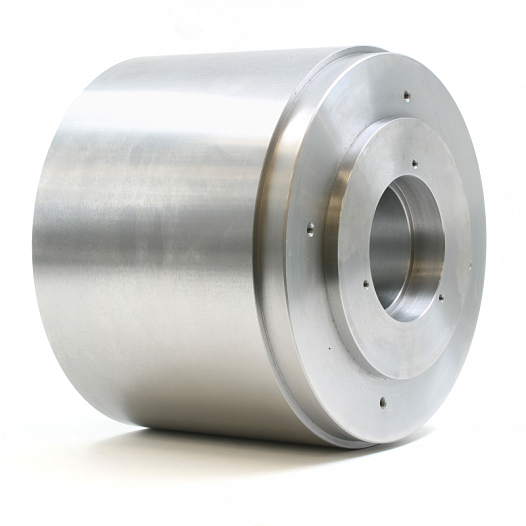

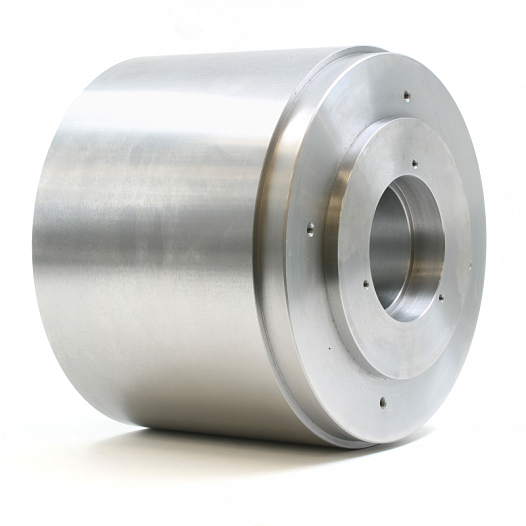

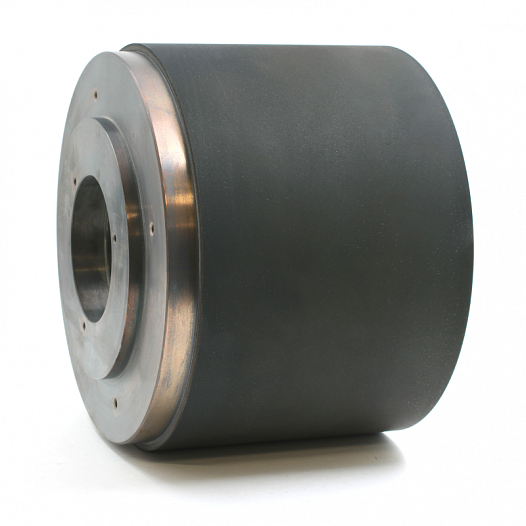

Automotive compressor rotors

Automotive compressor rotors

Before

After

MODENGY 1007 coating on rotors performs dynamic compaction function, makes the surfaces microrelief even what results in making running-in easier. Due to applying the coating, seizure and scores appearance on the parts are prevented, noise level at compressor running goes down.

Learn more about this solution

Parts of the line on making sausage goods

Parts of the line on making sausage goods

Before

After

In order to protect the equipment against exposure to adverse environmental factors, and corrosion appearing, MODENGY 1014 chemically resistant coating based on polytetrafluorethylene and molybdenum disulfide is applied.

Learn more about this solution

Ball valves plugs

Ball valves plugs

Before

After

This chemically resistant anti-friction coating reduces friction between the plug and the fluoroplastic saddle, and in this way provides retaining tightness of the unit, and extends service lifetime of the lock valves.

Learn more about this solution

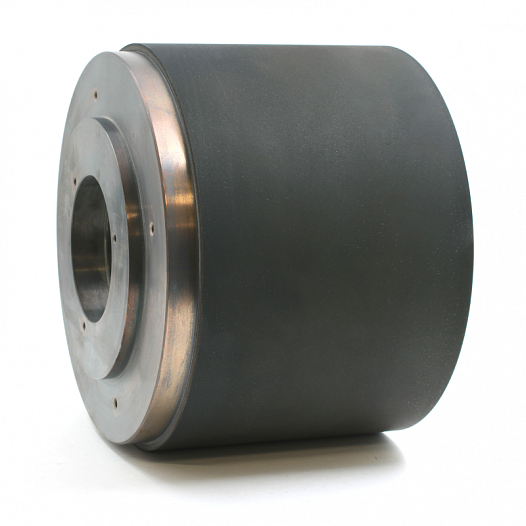

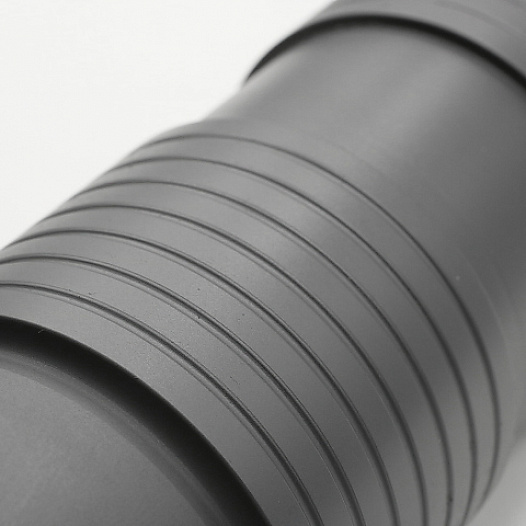

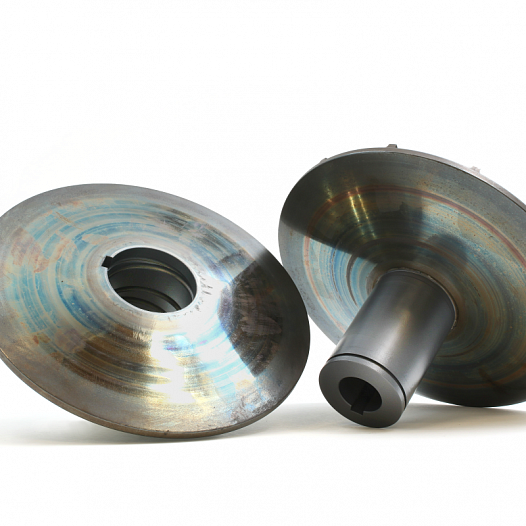

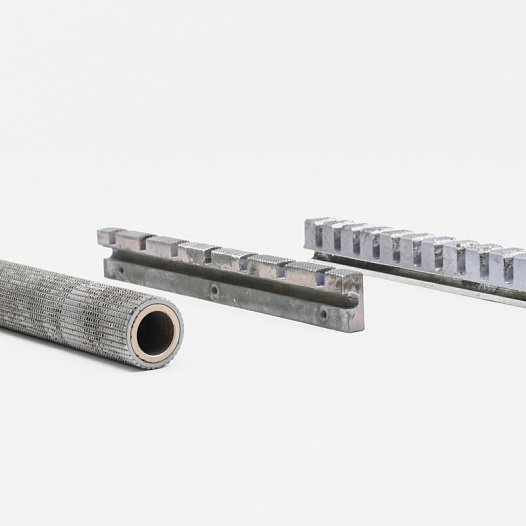

Rollers to smooth out a film

Rollers to smooth out a film

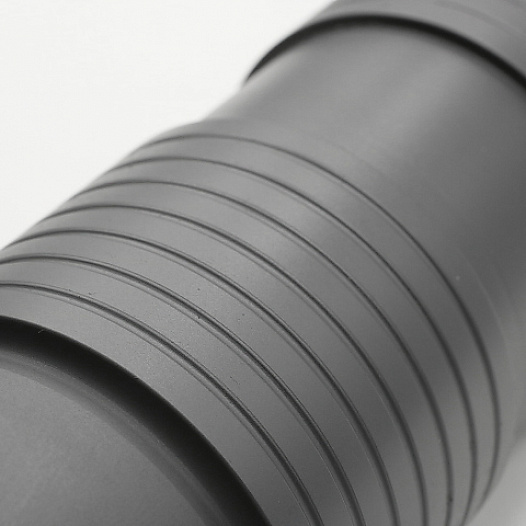

Before

After

To smooth out a film at producing polymer packs, special rollers are used. In order to prevent sticking as well as to make sliding of the polymer material easier, MODENGY 1007 coating is applied onto the parts.

Learn more about this solution

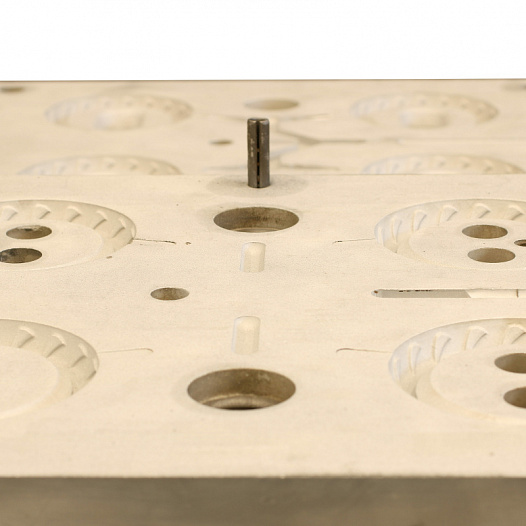

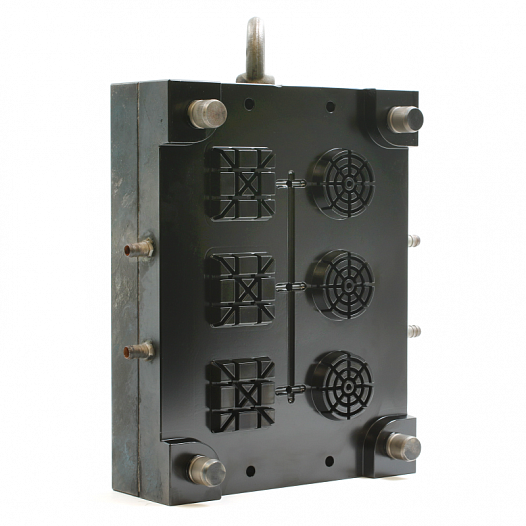

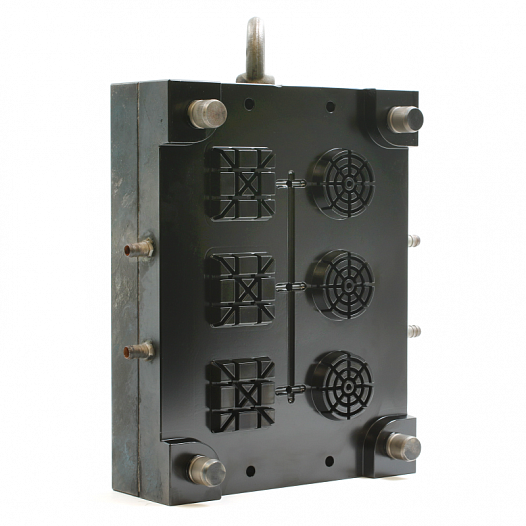

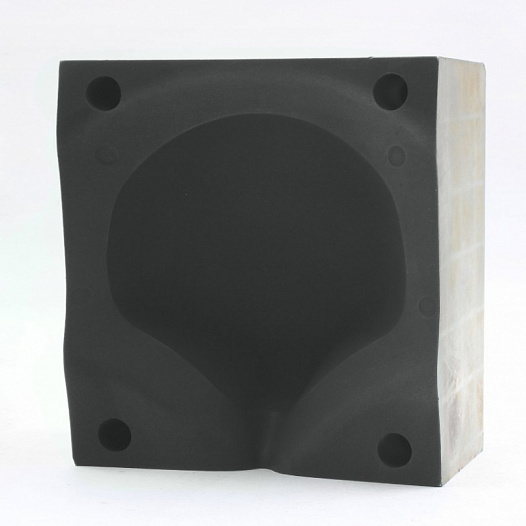

Moulds of the injection-molding machines

Moulds of the injection-molding machines

Before

After

Use of this coating prevents polymer sticking to the shape-generating surfaces, due to what quality of the products improves, equipment productivity increases, and service lifetime of the moulds extends.

Learn more about this solution

Cylinder head fasteners

Cylinder head fasteners

Before

After

Applying MODENGY 1001 coating onto the fastening items at mounting the head of the engine cylinder block enables to prevent seizure, sticking, and scuffing, and thus, to provide easy following dismantling of the connections.

Learn more about this solution

Heating elements to weld polymer pipes

Heating elements to weld polymer pipes

Before

After

MODENGY 1007 coating create a steady anti-sticking layer on the heating elements of the equipment for welding polypropylene pipes that prevents melted polymer from sticking, and improves seam quality in process of welding.

Learn more about this solution

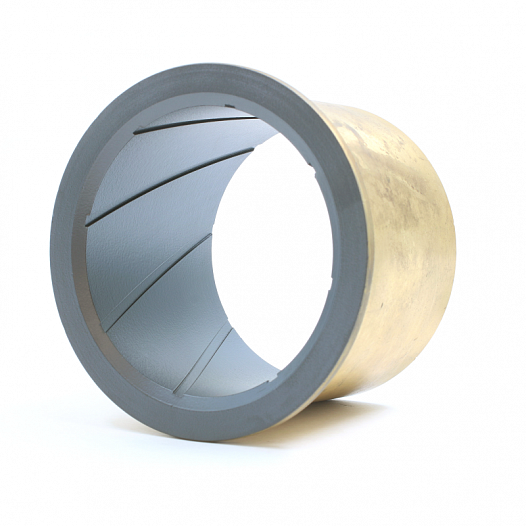

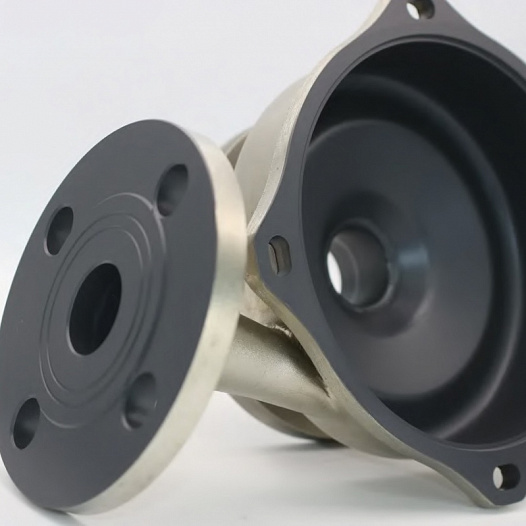

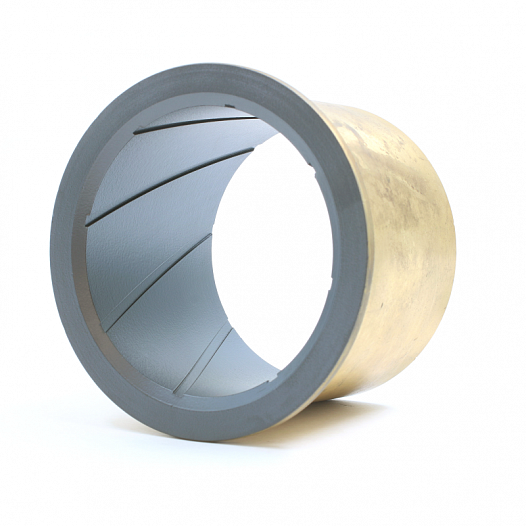

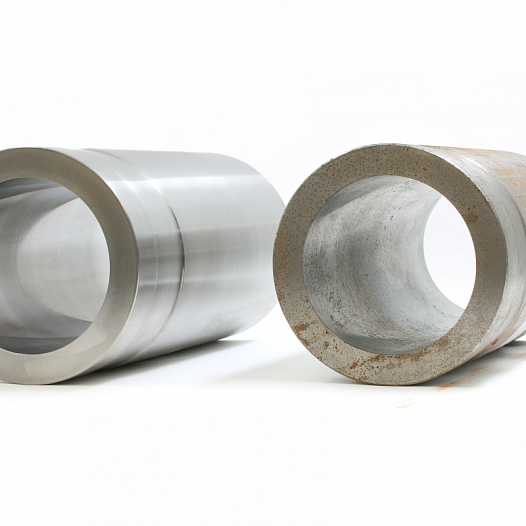

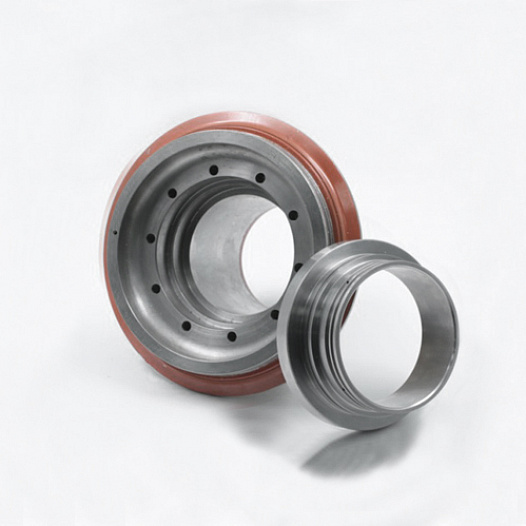

Bushings of the centrifuges to produce basalt fiber

Bushings of the centrifuges to produce basalt fiber

Before

After

Centrifuge drive shaft bushings function in pair with a rubber cuff that serves to prevent oil leakage.

In order to reduce wear of this cuff under conditions of high friction and high rotary speeds, to prevent it from burning onto the metal, MODENGY 1014 anti-friction solid-film coating is applied on the bushings.

Learn more about this solution

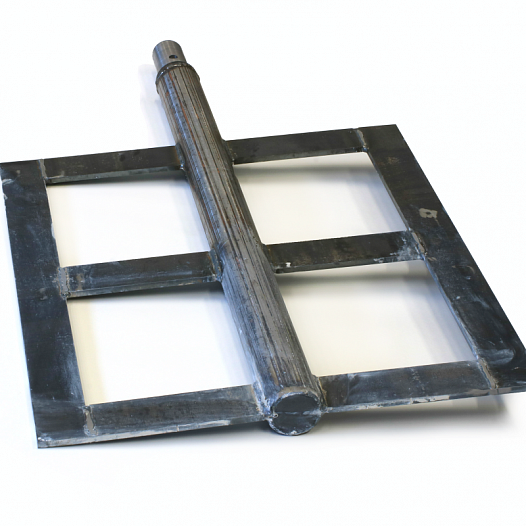

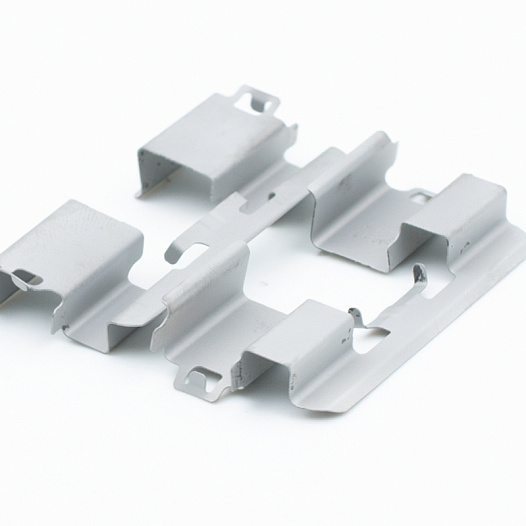

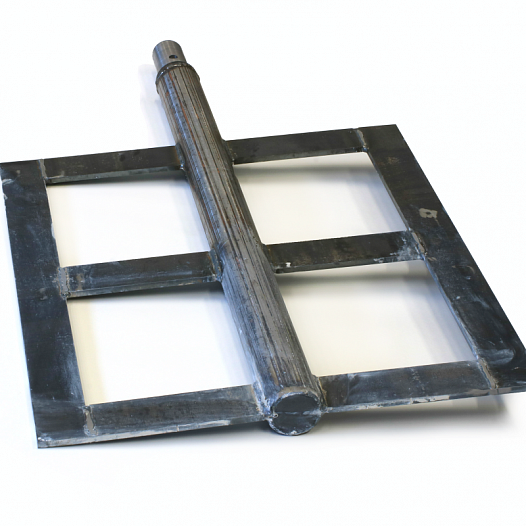

Squeegee frames elements

Squeegee frames elements

Before

After

The parts of the squeegee frames for screen printing that function being exposed to alkaline medium are subjected to corrosion, and become non-serviceable for further operating. Due to its high chemical resistance, MODENGY 1014 coating based on polytetrafluorethylene and molybdenum disulfide protects the parts against the aggressive medium, and prevents corrosion from forming. Besides, this product makes squeegee frames cleaning easier because it has anti-adhesive properties.

Learn more about this solution

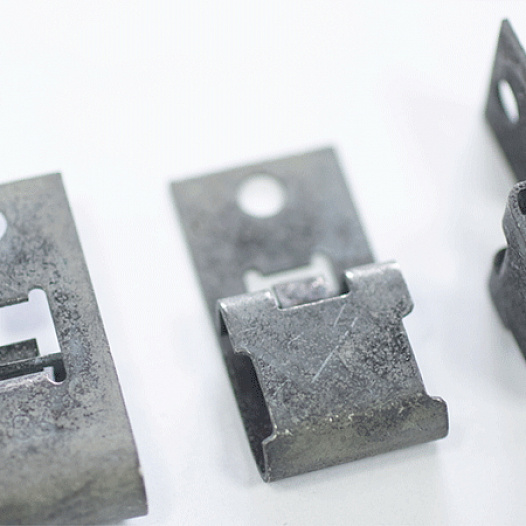

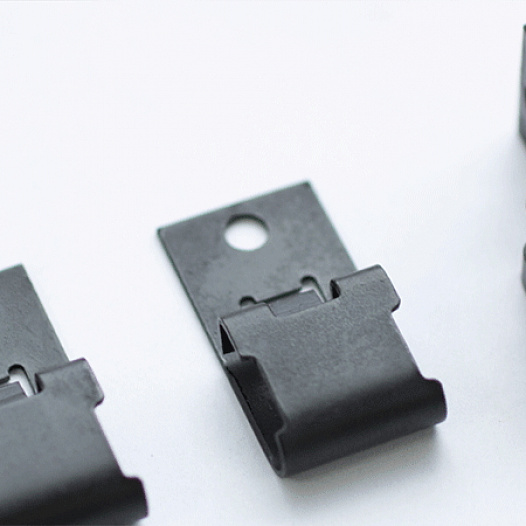

Fasteners for construction fabricated metals

Fasteners for construction fabricated metals

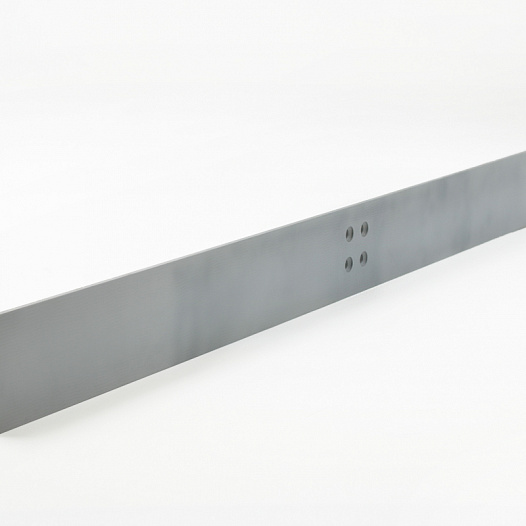

Before

After

To reduce and stabilize torsion coefficient of fasteners for the construction fabricated metals, MODENGY 1032 anti-friction solid-film coating based on polytetrafluorethylene is used. It is used in complex with a basic zinc flake coating, and besides stable torsion coefficient, provides long corrosion protection

Learn more about this solution

Calender shafts of the extrusion lines

Calender shafts of the extrusion lines

Before

After

To prevent the polystyrene tape from sticking to the calender shaft in process of hot pressing, MODENGY 1014 coating is used.

Learn more about this solution

Marine oil platform fasteners

Marine oil platform fasteners

Before

After

Coatings system consisting of a primer layer and MODENGY 1014 anti-friction solid-film coating based on polytetrafluorethylene and molybdenum disulfide provides long service lifetime of fastening items.

Learn more about this solution

Conveyors lip-type seal

Conveyors lip-type seal

Before

After

Applying MODENGY 1014 anti-friction solid-film coating on to the surface of the metal bushing provides low friction coefficient in the pair having a fluoroplastic cup, and in this way prevents wear of the latter.

Learn more about this solution

Compressor installations pistons

Compressor installations pistons

Before

After

MODENGY 1007 prevents wear of the pistons at oil lack: it reduces friction, protects against scuffing, and thus, significantly extends service lifetime of the compressors.

Learn more about this solution

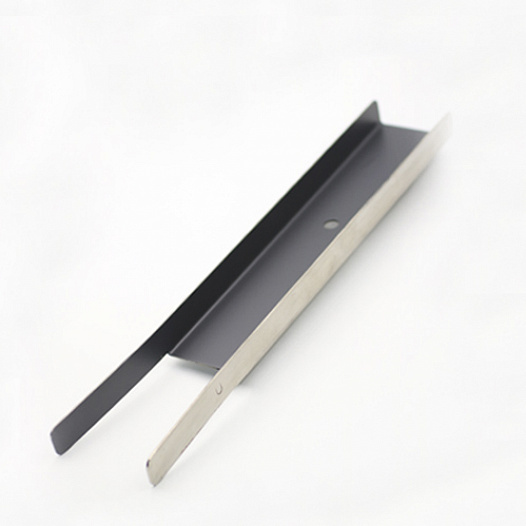

Edge-soldering plates of blister machines

Edge-soldering plates of blister machines

Before

After

An anti-adhesive coating on the edge-soldering elements of the blister machines is necessary to prevent heated packing polymer from sticking in process of thermoshaping.

Learn more about this solution

Threaded fasteners

Threaded fasteners

Before

After

The coatings system provides low and stable friction coefficient, long corrosion protection (more than 900 hours in the neutral salt mist according to ISO 9227 standard), possibility for multiple mounting and dismantling of the connections.

Learn more about this solution

Knives to cut and weld packs

Knives to cut and weld packs

Before

After

MODENGY 1007 anti-adhesive coating creates a steady separating layer on the knives to pack products into packs that protects parts from polyethylene sticking, and carbon deposits forming in process of cutting and seams welding.

Learn more about this solution

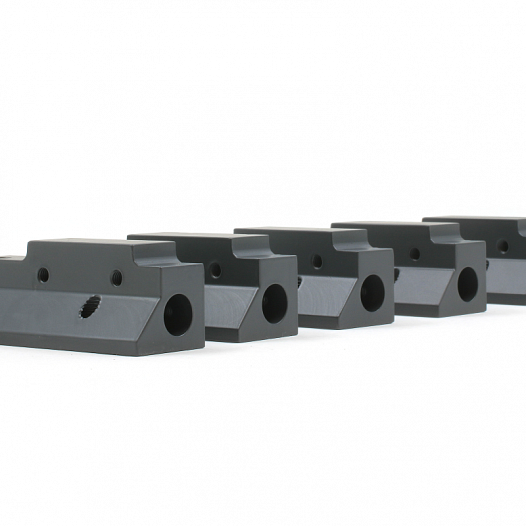

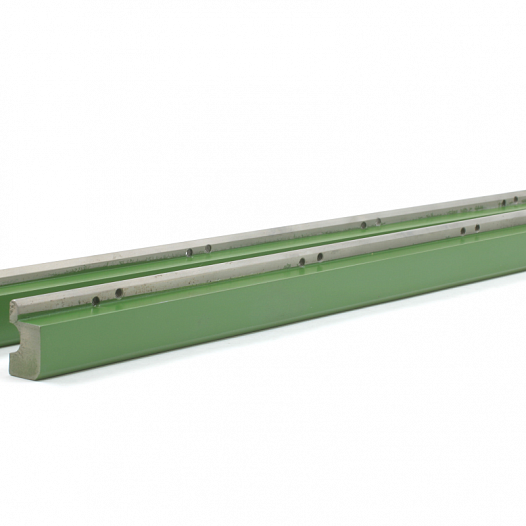

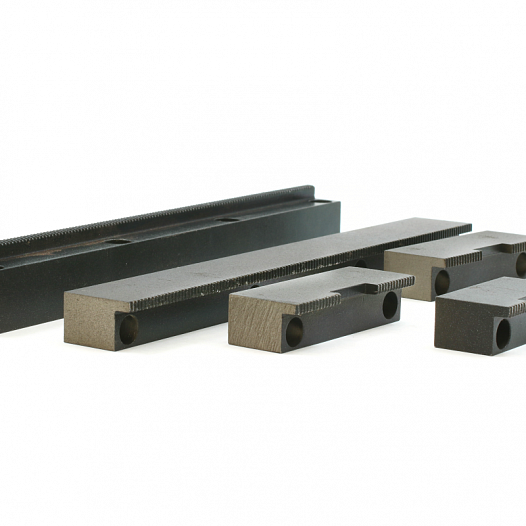

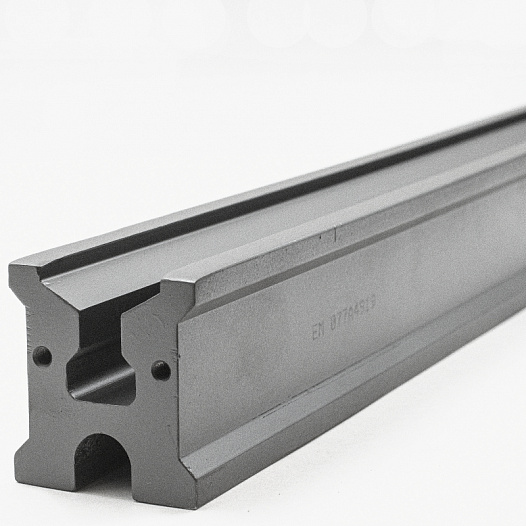

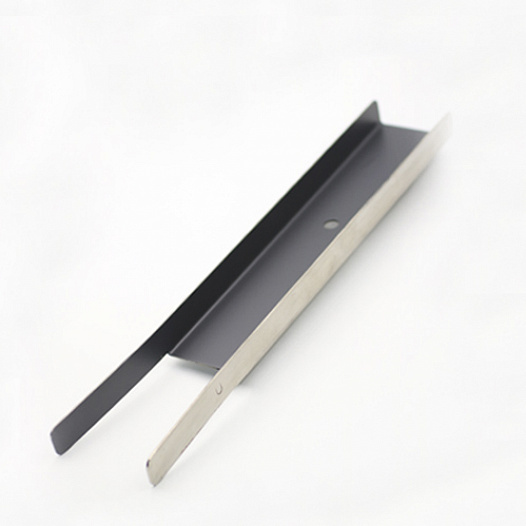

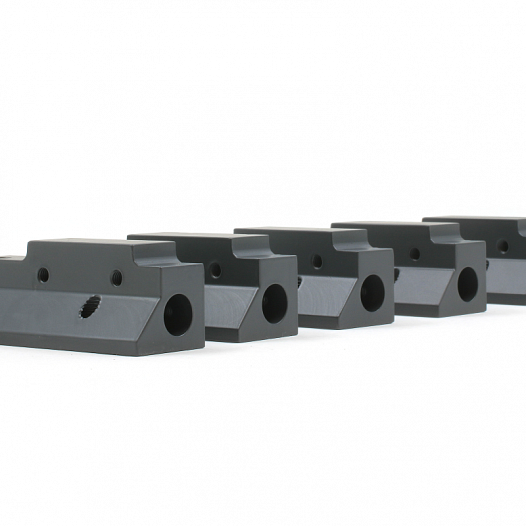

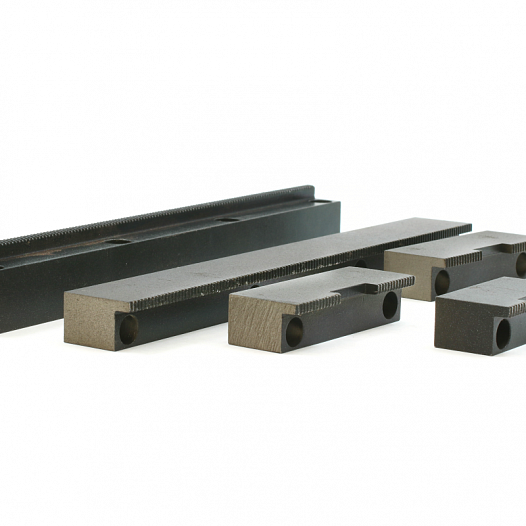

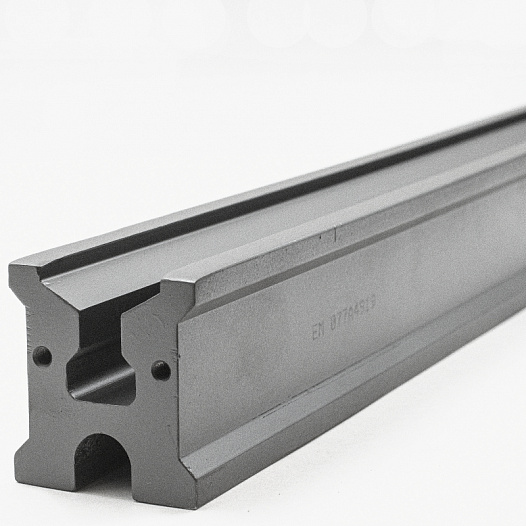

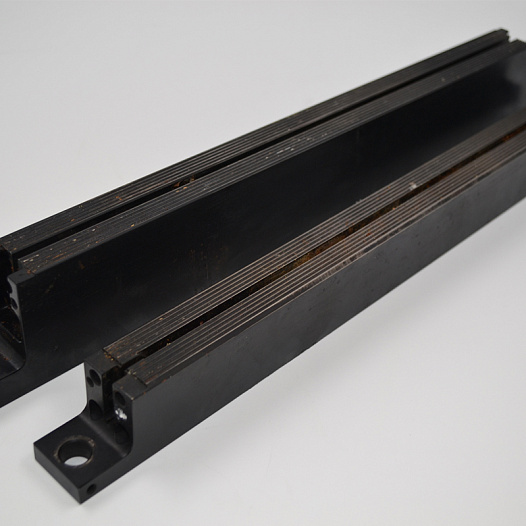

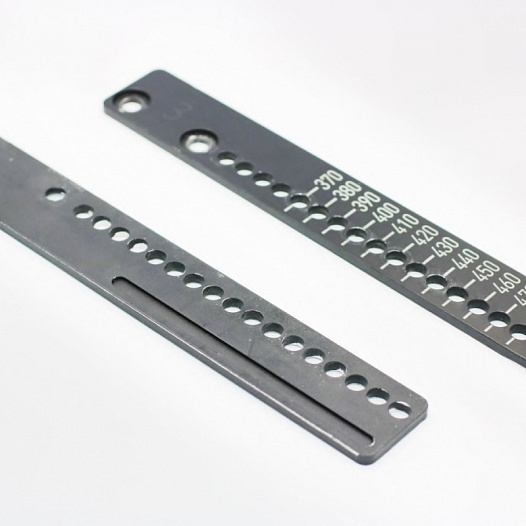

Сrimping machine tool guideways

Сrimping machine tool guideways

Before

After

It prevents slip-stick motion, and provides smooth moving of the crimping block while the machine tool is running.

Learn more about this solution

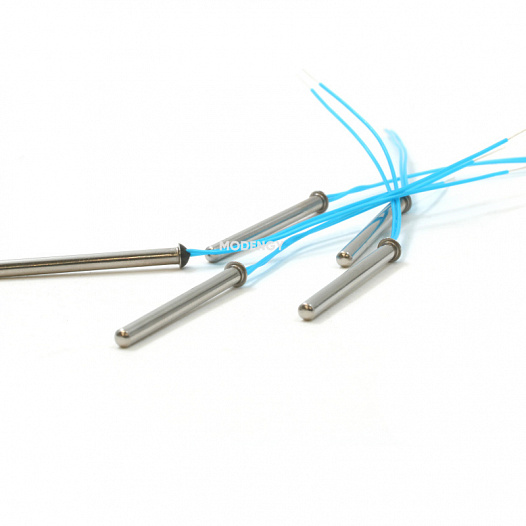

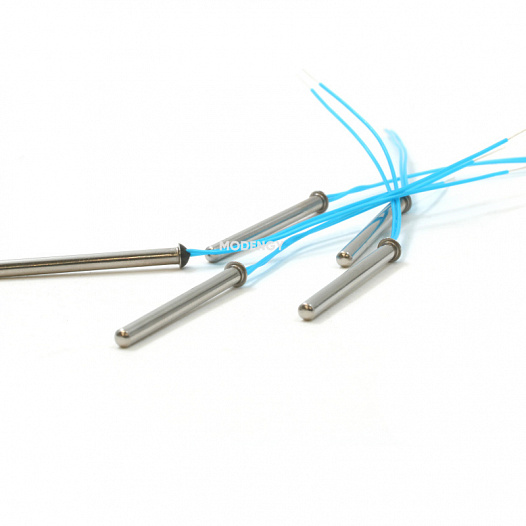

Fluid level sensors

Fluid level sensors

Before

After

For the purpose of extending service lifetime of the parts under aversive operational conditions as well as of preventing forming the deposits, MODENGY 1009 coating is applied onto the metal surfaces of the sensors.

Learn more about this solution

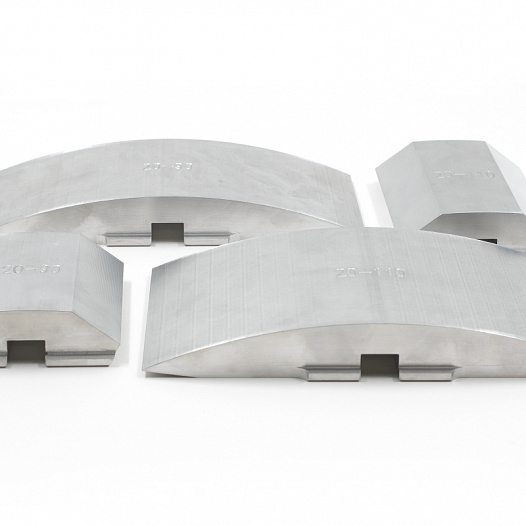

Crimping pads at sparkling wines production lines

Crimping pads at sparkling wines production lines

Before

After

In order to extend service lifetime of the crimping pads, MODENGY PTFE-A20 coating based on polytetrafluorethylene is used. It effectively reduces friction between rubber and foil improving operating and reducing wear of the equipment.

Learn more about this solution

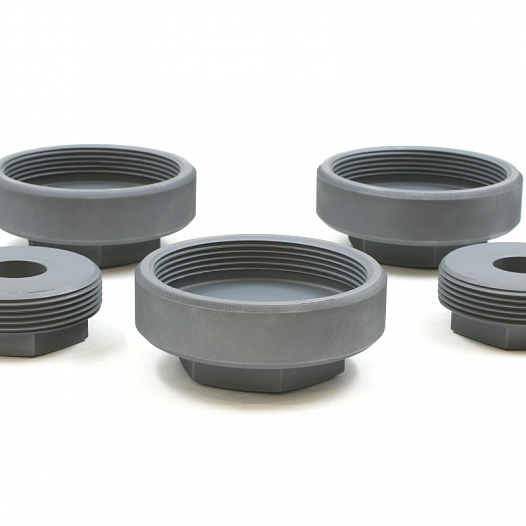

External skeletons' threaded bushings

External skeletons' threaded bushings

Before

After

MODENGY 1066 coating based on molybdenum disulfide and graphite is applied onto the external skeletons' thrust threaded bushings made of stainless steel. It solves an acute issue of thread galling at screwing and unscrewing connections.

Learn more about this solution

Edgebanders parts

Edgebanders parts

Before

After

In order to prevent this sticking, and to provide easy glue removing off the glue tubs and the guideways of the machine tool where the heated material can also get, MODENGY 1007 coating with high anti-adhesive properties is used.

Learn more about this solution

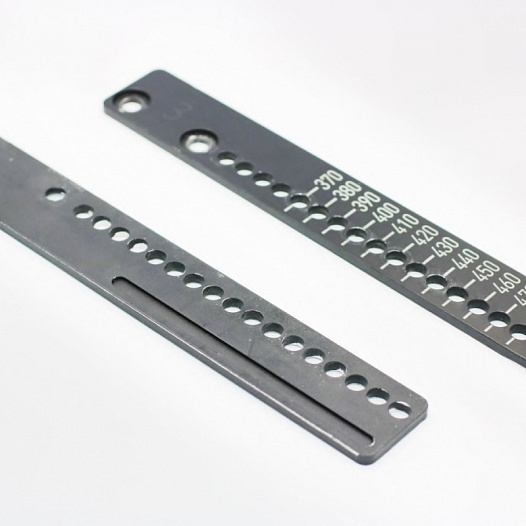

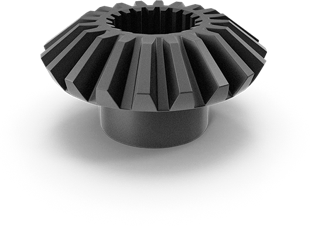

Gearwheel pinions

Gearwheel pinions

Before

After

This coating based on molybdenum disulfide has high load-carrying capacity, low friction coefficient, operability in dusty environment (no small particles get stuck onto a dry lubrication layer). Due to this, applying this product enables to extend service lifetime of the lifting equipment considerably.

Learn more about this solution

Heating shafts of the machine tools for bearings production

Heating shafts of the machine tools for bearings production

Before

After

Applying MODENGY 1007 anti-adhesive coating enables to exclude lacquer sticking and burning to the shafts, to provide easy parts cleaning with a rag.

Learn more about this solution

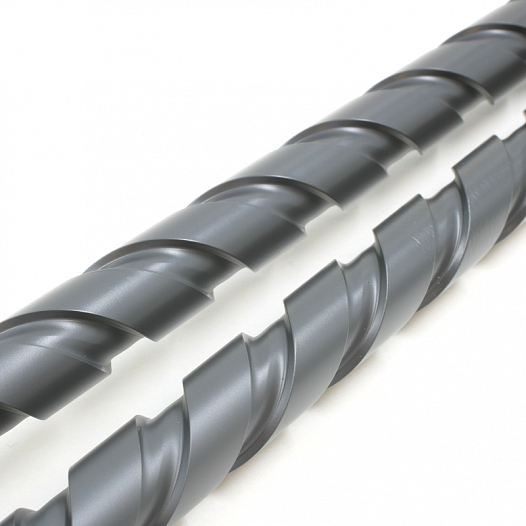

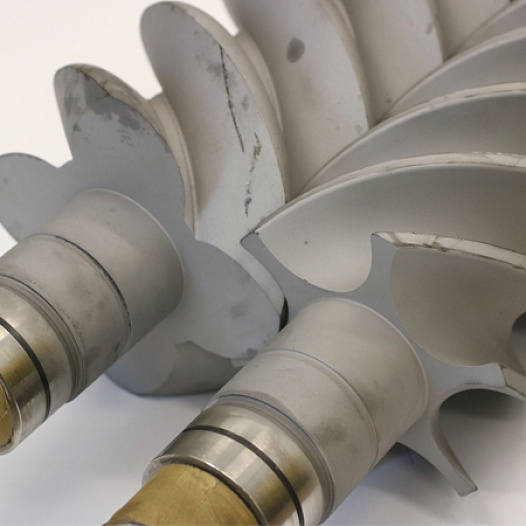

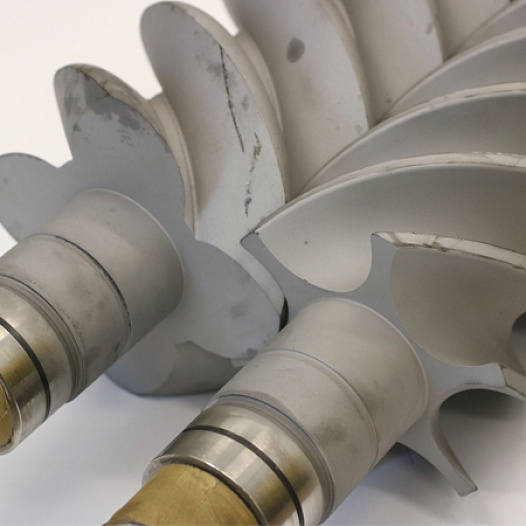

Injection molding machines screws

Injection molding machines screws

Before

After

MODENGY 1007 anti-adhesive coating provides melted mass going through without sticking to the screws surfaces, due to what necessity to stop the injection molding machines to clean the screws is eliminated, lines passing ability grows, and service lifetime of the equipment extends.

Learn more about this solution

Axial-piston pump parts

Axial-piston pump parts

Before

After

Use of MODENGY 1003 coating enables to reduce prime cost of axial-piston pumps production.

Learn more about this solution

Pressure sensors

Pressure sensors

Before

After

MODENGY 1007 effectively prevents melted polymer material sticking onto the sensors elements providing reliable equipment operating, and keeping measurements accuracy.

Learn more about this solution

Knives for packaging film

Knives for packaging film

Before

After

A separative layer of the coating prevents direct contact between the melted film and the knives surfaces solving the issue of sticking and burning the packaging material onto the tools.

Learn more about this solution

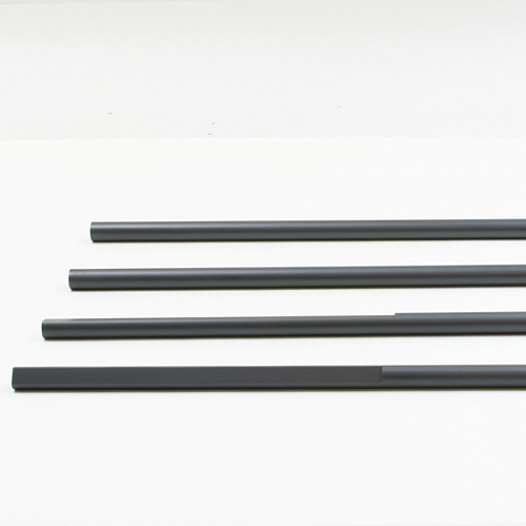

Lead screws

Lead screws

Before

After

MODENGY 1025 significantly reduces friction coefficient, improves smoothness of transmission going, accumulates no dust and dirt from environment on the part’s surface.

Learn more about this solution

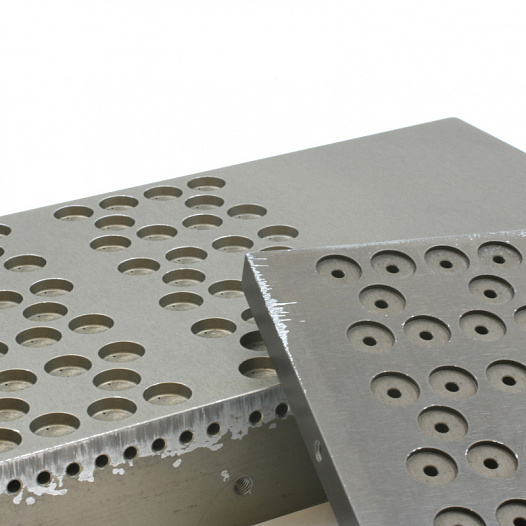

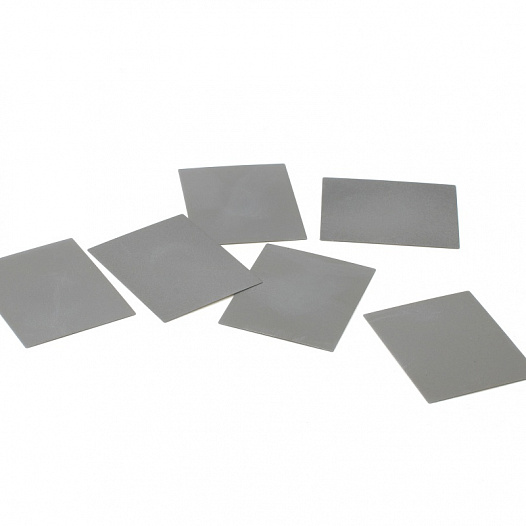

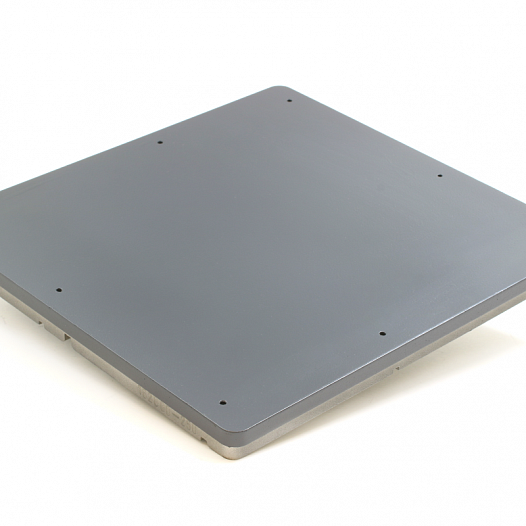

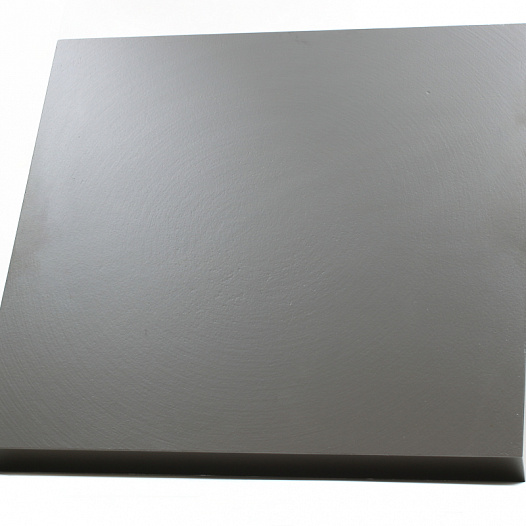

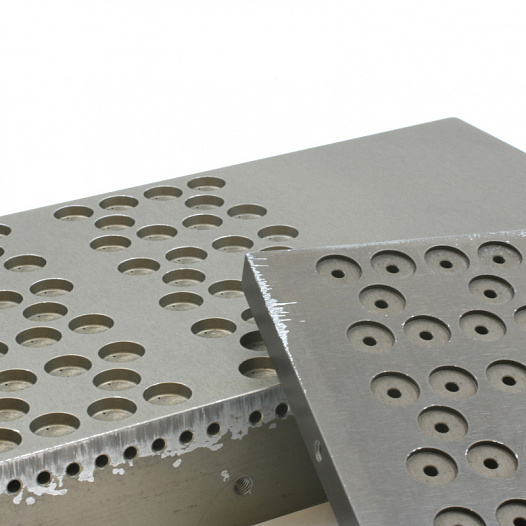

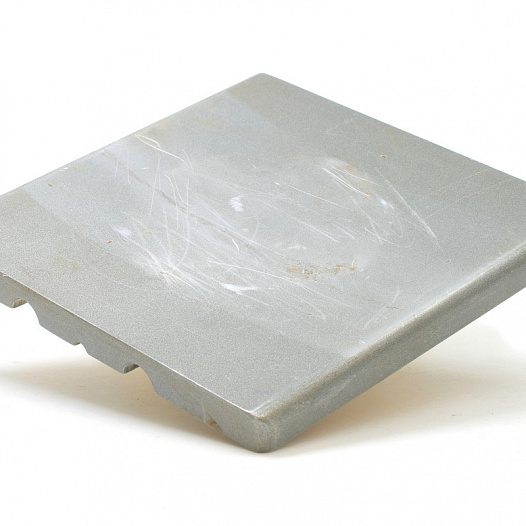

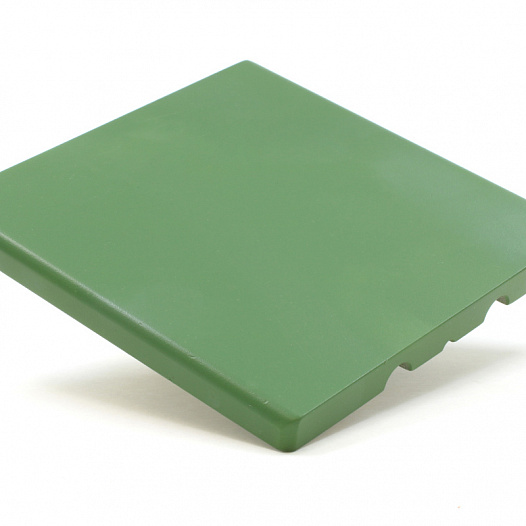

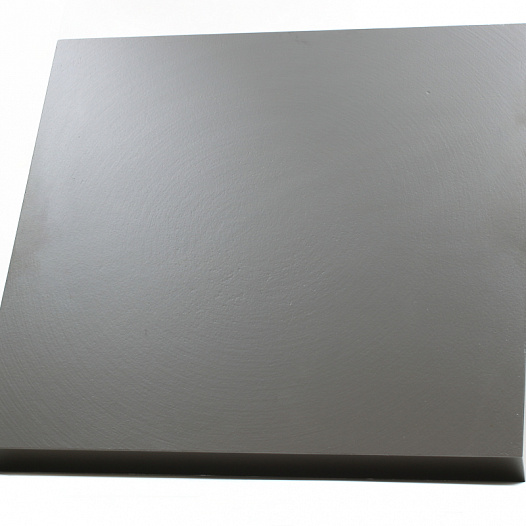

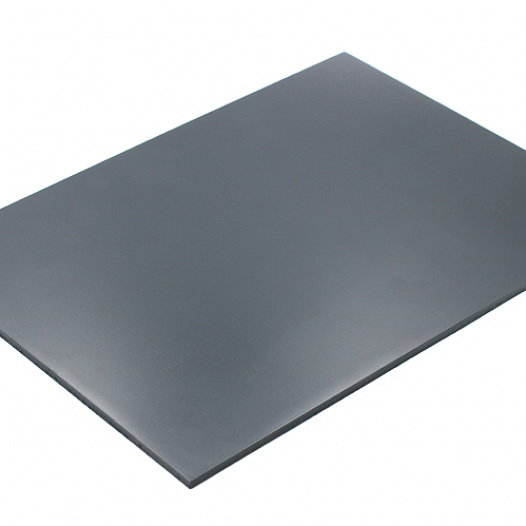

Moulding plates

Moulding plates

Before

After

Due to its anti-adhesive properties, MODENGY PTFE-A 20 coating based on polytetrafluorethylene prevents polymer material from sticking to the surfaces of the plates in process of moulding a blister type package for pharmaceutical preparations.

Learn more about this solution

Edge-soldering plates

Edge-soldering plates

Before

After

To provide effective trouble-free process of packing pharmaceutical dosage forms, a coating with high anti-adhesive properties approved to contact with medicines is applied onto the surfaces of the edge-soldering plates.

Learn more about this solution

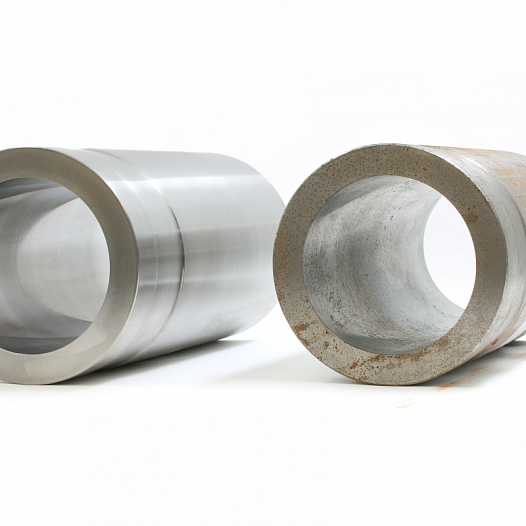

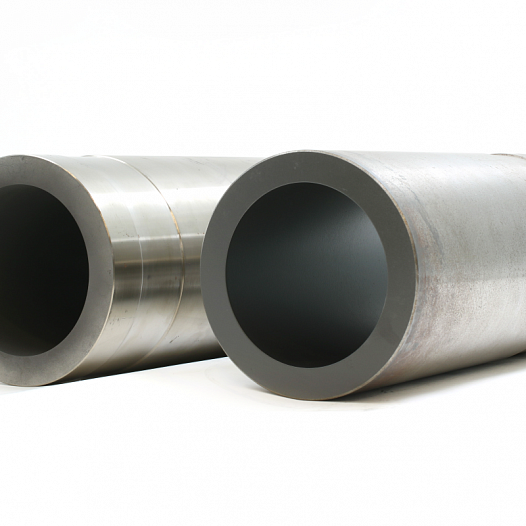

Undersea robots hydraulic cylinders bushings

Undersea robots hydraulic cylinders bushings

Before

After

MODENGY 1066 coating based on molybdenum disulfide and graphite is applied onto internal surfaces of the hydraulic cylinders.

It not only provides effective corrosion protection for the entire service lifetime of the parts but also improves smoothness of hydraulic cylinder going, and thus expends service term and improves reliability of robot systems operating.

Learn more about this solution

Heating elements

Heating elements

Before

After

The coating with high anti-friction and anti-adhesive properties makes sliding of the material along the heating elements surface easier, and prevents paper from burning to the metal surface.

Learn more about this solution

Cases and connectors of globe valves

Cases and connectors of globe valves

Before

After

To protect air-gas channels of the globe valves parts against corrosion while operating within natural gas medium,

MODENGY 1014 chemically resistant coating is used.

Learn more about this solution

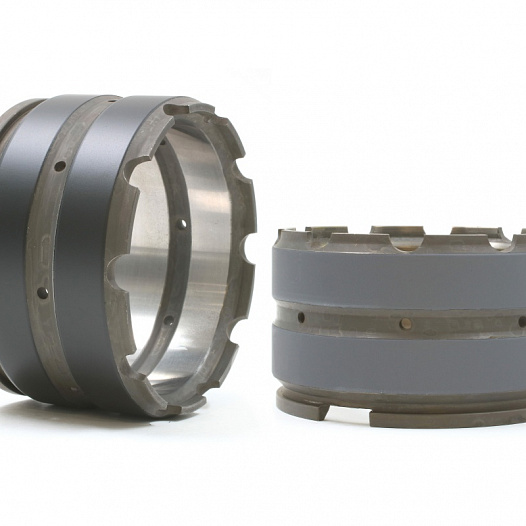

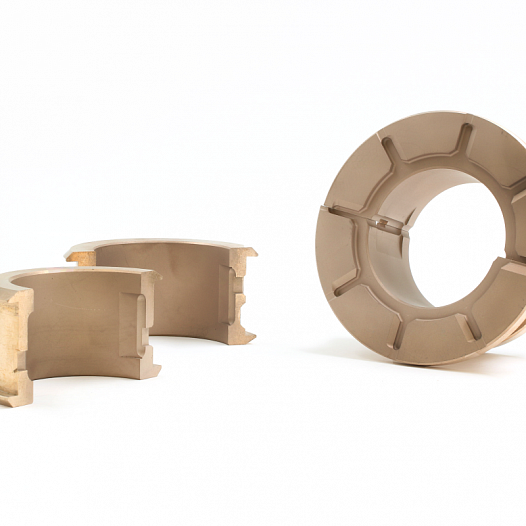

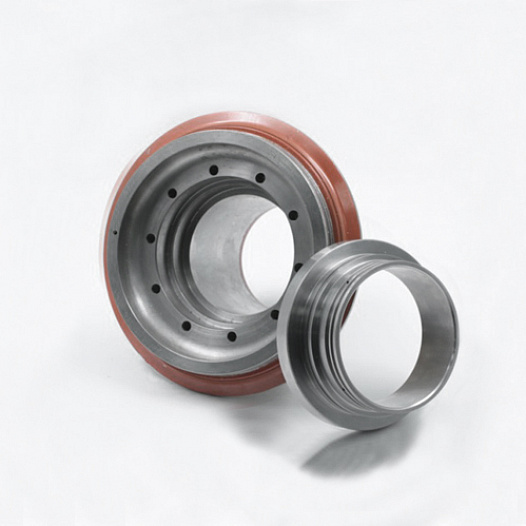

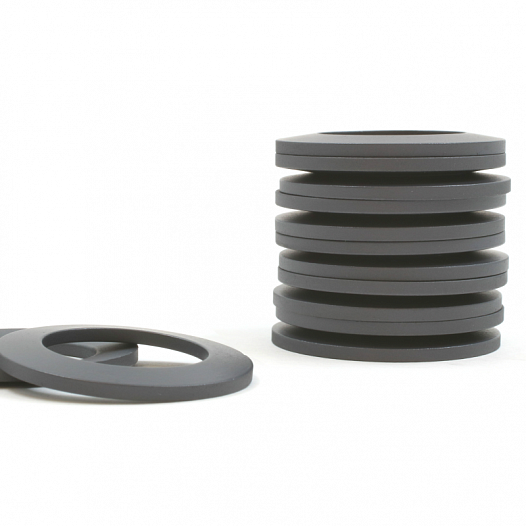

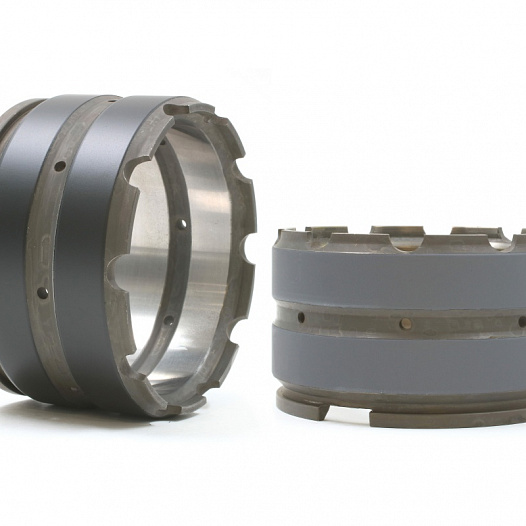

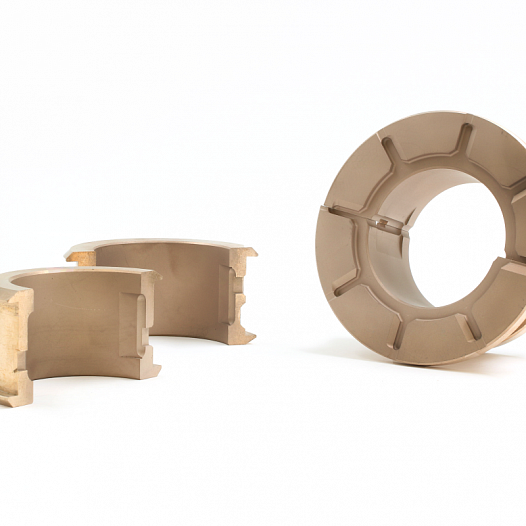

Rings of dry gas seals

Rings of dry gas seals

Before

After

In order to extend service lifetime of the dry gas seals, MODENGY 1006 anti-friction solid-film coating based on molybdenum disulfide and graphite is applied onto the ring surfaces facing each other. This reduces friction between the contacting surfaces decreasing parts wear, and eliminating excessive noise while the superchargers are operating.

Learn more about this solution

Media separators

Media separators

Before

After

To protect the separator cases against aggressive media impact, MODENGY 1014 chemically resistant coating based on polytetrafluorethylene and molybdenum disulfide is used.

Learn more about this solution

Knives of the machines to make packs

Knives of the machines to make packs

Before

After

MODENGY 1007 coating forms a steady separating layer on the cutting knife that prevents polyethylene from sticking to the heated surface of the tool, and forming carbon deposit. Due to this, quality trouble-free film soldering and cutting-off is provided at producing packs.

Learn more about this solution

Pipeline fitting valves lock rings

Pipeline fitting valves lock rings

Before

After

This coating provides corrosion protection for the parts making fitting them into the grooves easier. This material has high wear resistance and long service lifetime, requires no renewal for the entire service term of the lock rings.

Learn more about this solution

Edge-soldering elements to seal packs

Edge-soldering elements to seal packs

Before

After

In order to get a quality weld seam on packs, MODENGY 1007 anti-adhesive coating is applied onto the edge-soldering elements.

Learn more about this solution

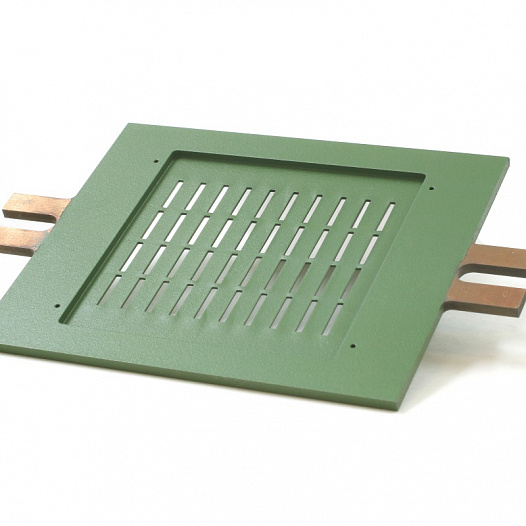

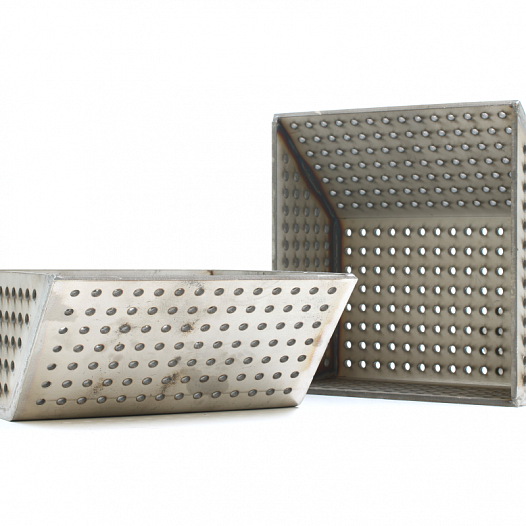

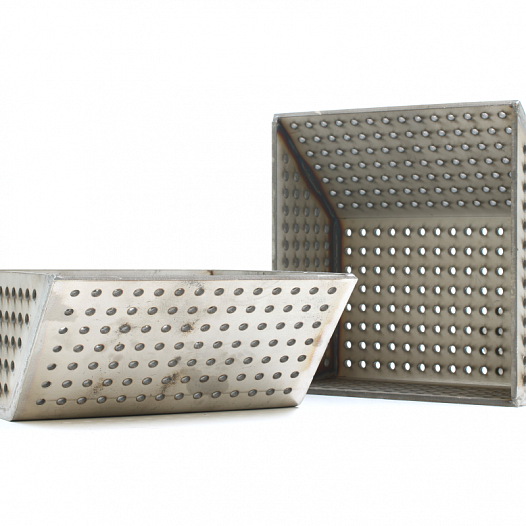

Equipment to produce reverse osmosis filters

Equipment to produce reverse osmosis filters

Before

After

At filling the filtering elements, powdery polymer materials stick to the metering trays because of high humidity. To solve the issue of sticking, an

anti-adhesive coating is applied onto the trays. It forms a steady smooth layer

providing easy granules transporting without sticking to the equipment

surfaces.

Learn more about this solution

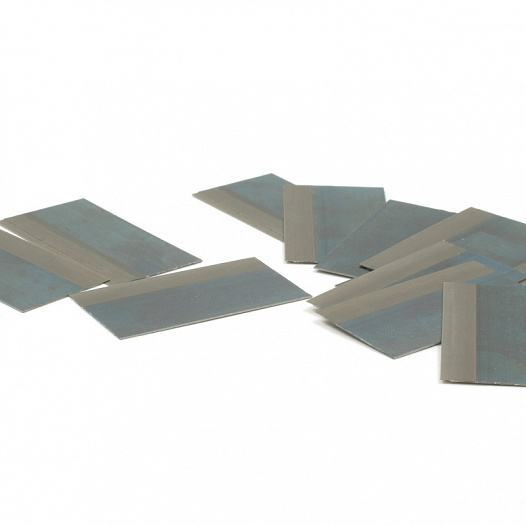

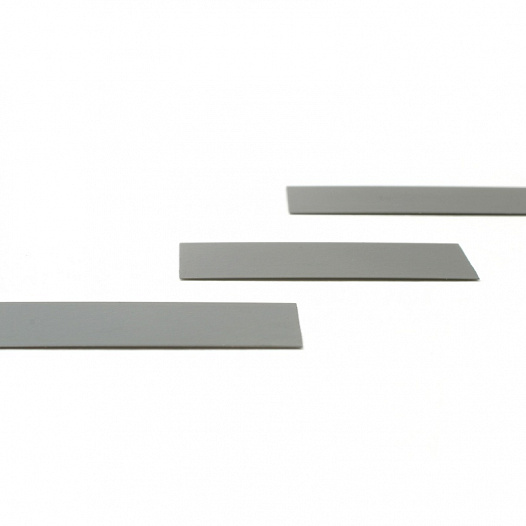

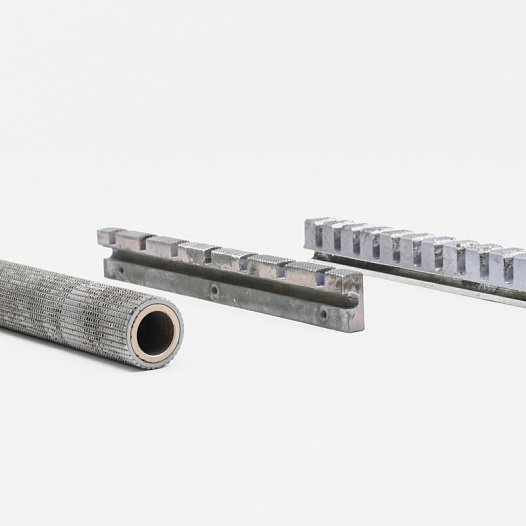

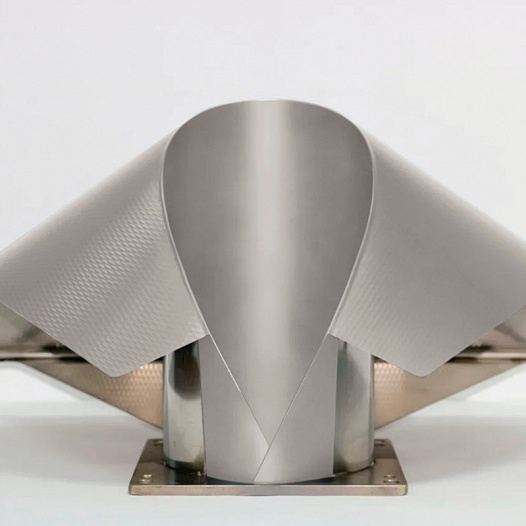

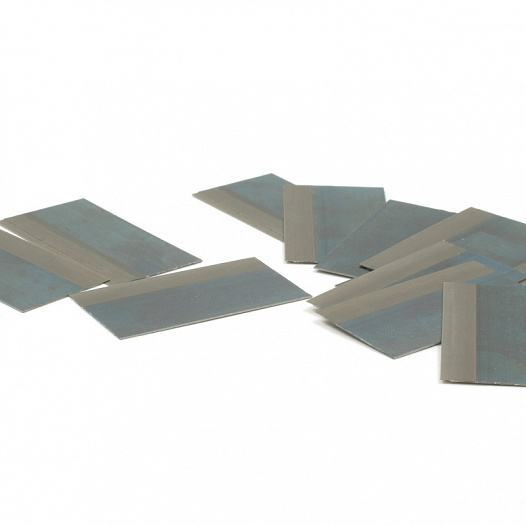

Gasodynamic bearings petals

Gasodynamic bearings petals

Before

After

To reduce friction at the moments of starting and stopping the power plants, MODENGY 1090 and MODENGY 2560 coatings are applied onto the work surfaces of the workpieces of gasodynamic bearings petals.

Learn more about this solution

Vacuum plates for machines to process leather

Vacuum plates for machines to process leather

Before

After

In order to provide smooth going of the knives, and to reduce wear of the surfaces, MODENGY 1007 anti-friction solid-film coating is applied onto the vacuum plates.

Learn more about this solution

Tyre studding devices

Tyre studding devices

Before

After

To provide aesthetic appearance for the parts, MODENGY 1003 and MODENGY 1009 solid-film coatings are used. MODENGY 1009 also protects the parts against corrosion extending their service lifetime. The coatings need no renewing for the entire operation period of the tyre studding devices.

Learn more about this solution

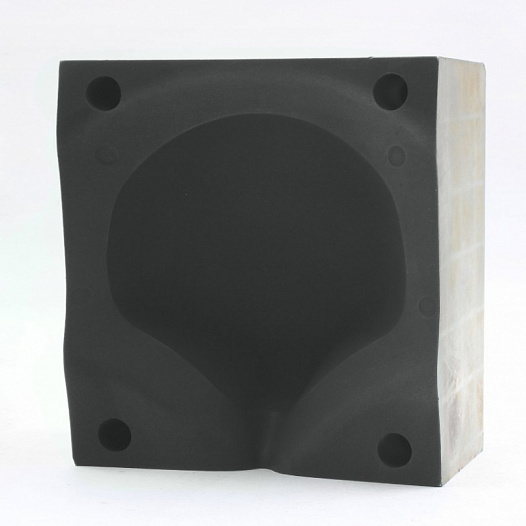

Slide bearing with the system for diagnostics of surface wear limit value

Slide bearing with the system for diagnostics of surface wear limit value

Before

After

MODENGY 1003 anti-friction solid-film coating is used to reduce friction, wear, to prevent the slide bearing working surface damage in process of operating it.

Learn more about this solution

Hydraulic distributor shutters

Hydraulic distributor shutters

Before

After

To reduce friction coefficient, MODENGY 1005 and MODENGY 1003 anti-friction solid-film coatings are applied onto the rod surfaces. Due to use of these coatings, reliability of the hydraulic distributor improves, their service lifetime extends, and lifetime lubrication of the unit is provided.

Learn more about this solution

Parts of treating machine tools

Parts of treating machine tools

Before

After

To provide smooth going of the unit, and to extend service lifetime of the parts, MODENGY 1066 coating is applied onto the contacting surfaces. It reduces friction coefficient, prevents stick-slip motion, provides lifetime lubrication of the elements.

Learn more about this solution

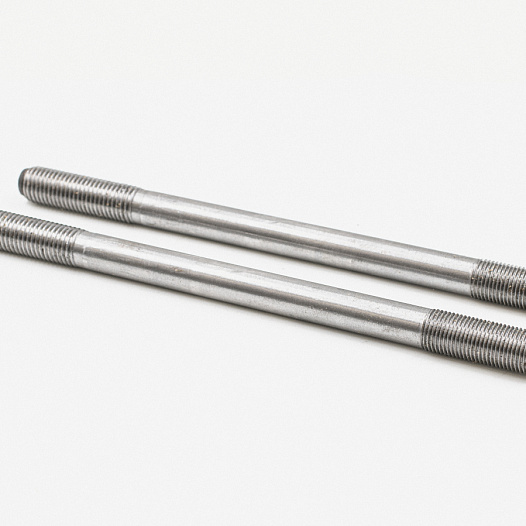

Pipe coupling studs

Pipe coupling studs

Before

After

In order to make the tightening process easier, to provide protection against the scuffing and jamming, MODENGY 1001 anti-friction solid-film coating is applied onto the studs of the joint couplings. It creates a steady lubricating layer on the threaded elements that excludes direct contact between the metal surfaces.

Learn more about this solution

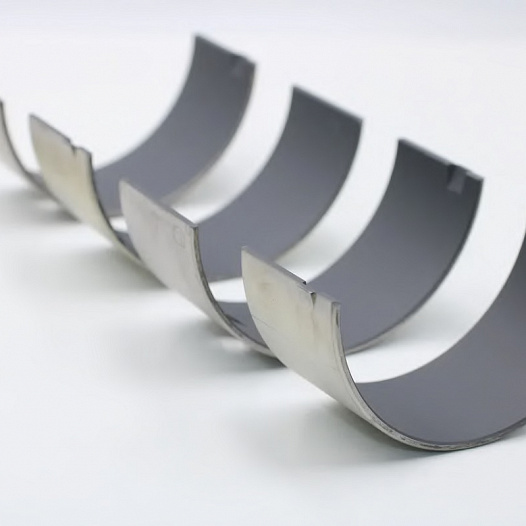

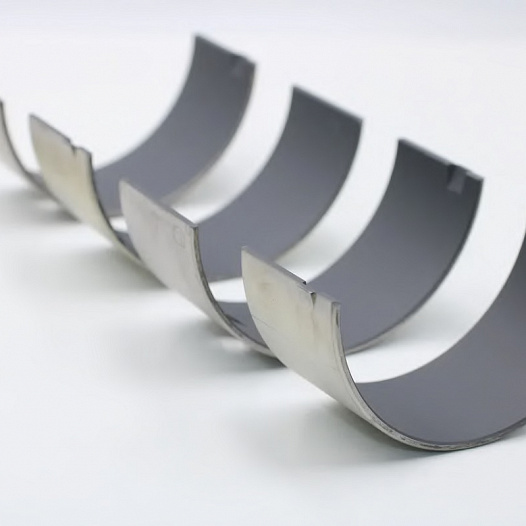

Diesel generators engine inserts

Diesel generators engine inserts

Before

After

In order to reduce wear, and to extend service lifetime, MODENGY 1006 anti-friction solid-film coating based on molybdenum disulfide and graphite is applied onto working surfaces of diesel generators inserts.

Learn more about this solution

Bearings of the wheels made of heat-resistant glass-fibre plastic

Bearings of the wheels made of heat-resistant glass-fibre plastic

Before

After

To reduce friction in the wheel-to-bushing pair, and to provide long reliable operation of the trolley wheels, MODENGY 1003 and MODENGY 1014 anti-friction solid-film coatings are applied onto the bearings.

Learn more about this solution

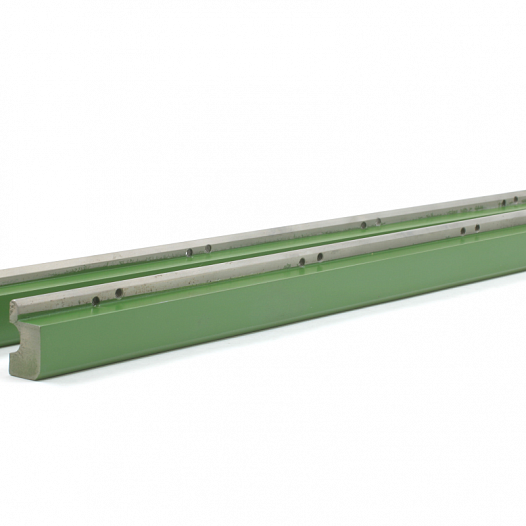

Parts of the unit to produce bagged tea

Parts of the unit to produce bagged tea

Before

After

In order to guideways and side clamping elements don’t wear out, and keep on functioning, an anti-friction coating is applied onto their surfaces that provides dry and clean lubrication.

Learn more about this solution

Silicone potting moulds

Silicone potting moulds

Before

After

In order to prevent potting material from sticking to the mould which the parts potting with silicone and epoxy compounds is fulfilled through, an anti-adhesive coating is used.

Learn more about this solution

Mould to make toys of PVC

Mould to make toys of PVC

Before

After

MODENGY 1014 coating with anti-adhesive properties is used to prevent PVC from sticking to the mould internal surface at making toys which causes defective products.

Learn more about this solution

Industrial mixers screws

Industrial mixers screws

Before

After

To provide longterm corrosion protection, and to prevent materials from sticking onto the mixer screws, MODENGY 1011 solid-film coating with high anti-adhesive and anti-corrosive properties is applied.

Learn more about this solution

Wheels of the high-temperature kiln trolleys

Wheels of the high-temperature kiln trolleys

Before

After

Applying MODENGY 1005 coating onto wheels bearings enables to reduce friction and wear, to eliminate squeak while moving, to prevent stick-slip motion.

Learn more about this solution

Packaging equipment parts

Packaging equipment parts

Before

After

A separating layer of the coating excludes packing material sticking to edge-soldering elements and knives, reducing amount of defective items, and extending service lifetime of the equipment.

Learn more about this solution

Equipment for restaurants and food productions

Equipment for restaurants and food productions

Before

After

Applying a food-grade anti-sticking product is a save-price and efficient alternative for replacing the molds for frying with worn coating for the new ones.

Learn more about this solution

Bushings of internal downhole equipment

Bushings of internal downhole equipment

Before

After

To protect the bushings of the internal downhole equipment against negative external factors, MODENGY 1014 chemically resistant coating containing polytetrafluorethylene and molybdenum disulfide is used.

Learn more about this solution

Knives to cut bags

Knives to cut bags

Before

After

Due to its anti-adhesive properties, this coating prevents polyethylene from sticking to hot surfaces of the cutting tools, protects against forming carbon deposits, increases work efficiency of the machines on making plastic bags.

Learn more about this solution

Microturbine gas-dynamic bearings

Microturbine gas-dynamic bearings

Before

After

To extend service lifetime of the gas-dynamic bearings, MODENGY 1090 anti-friction coating is applied onto the operational surfaces of the petals. It withstands extremely high temperatures (up to +730 °С), and loads what enables this product to operate efficiently in the bearings of the microturbine plants.

Learn more about this solution

Edge-soldering plates of packing machines

Edge-soldering plates of packing machines

Before

After

A separating layer of the coating protects the heated edge-solderer against polymer material sticking-on, due to what productivity of the packing line increases, and amount of defective items get minimized.

Learn more about this solution

End-soldering elements of packing machinery

End-soldering elements of packing machinery

Before

After

To avoid packaging material sticking onto the heated surfaces of the end-soldering elements, MODENGY 1007 anti-adhesive coating is used. It keeps its operability at high temperatures (up to +350 °C), and needs no renewing.

Learn more about this solution

Knife of the machine tool to produce package

Knife of the machine tool to produce package

Before

After

MODENGY 1007 anti-adhesive coating applied onto the knife work surface prevents the melted film from sticking in process of forming the seams.

Learn more about this solution

Vacuum edge-solderers

Vacuum edge-solderers

Before

After

To provide proper operation of the edge-solderers, MODENGY 1014 separating coating is used. It excludes contact between the heated film and the metal surfaces, and thus solves the issue of film sticking, and carbon deposits forming.

Learn more about this solution

Equipment to form facets of paper containers

Equipment to form facets of paper containers

Before

After

To prevent heated film from sticking to the equipment surface, an anti-adhesive coating is used. It operates effectively at up to +350 °С, doesn't break heat exchange between the surfaces, requires no renewing for a long while.

Learn more about this solution

Equipment for printing on a sticky tape

Equipment for printing on a sticky tape

Before

After

To prevent the sticky lover of the tape from sticking to the drum in process of printing, a coating with high anti-adhesive properties is used. It separates the surfaces of the drum and the tape, due to what quality and continuous image putting is provided.

Learn more about this solution

Oil pump thrust bearings

Oil pump thrust bearings

Before

After

MODENGY 1006, and MODENGY 1066 reduce friction at the moments of starting and stopping as well as extend service lifetime of the highly loaded thrust bearings.

Learn more about this solution

Parts of the equipment to output dispensable package

Parts of the equipment to output dispensable package

Before

After

In order to prevent the heated packaging material from sticking to the tools, MODENGY 1007, and MODENGY 1014 coatings with high anti-adhesive properties are used.

Learn more about this solution

Glue pan of edgebander

Glue pan of edgebander

Before

After

In order to prevent the glue from sticking and burning to the glue pan edges, to make cleaning and maintaining it easier, MODENGY 1007 coating with high anti-adhesive properties is used.

Learn more about this solution

Polyethylene film cooler

Polyethylene film cooler

Before

After

For the purpose of eliminating heated film sticking to the surface of the cooler, MODENGY 1007 anti-adhesive coating is used. It creates a thin separating layer on the cooler that prevents the polymer film from sticking.

Learn more about this solution

Cutting-off knives of the equipment to produce plastic caps

Cutting-off knives of the equipment to produce plastic caps

Before

After

In order to prevent the melted polymer material from sticking to the cutting-off knives, MODENGY 1007 anti-adhesive coating is used. Due to this, process of defects removing gets optimized, and a number of defected products reduces.

Learn more about this solution

Packing equipment cutting-off knives

Packing equipment cutting-off knives

Before

After

To prevent film from sticking to the knives in process of creating cuttoff seams, MODENGY 1014 anti-adhesive coating is used. It has high separating properties, and long service lifetime, enables to increase productivity of the packing line, and to reduce a number of defective products.

Learn more about this solution

Tetra Pak packing plant knives

Tetra Pak packing plant knives

Before

After

Food-grade wear-resistant anti-adhesive coating enables to solve the issue of packing material sticking. A separating layer prevents film from contacting and sticking to the metal surface of the edge-soldering knife, due to what seams quality improves, and efficiency of equipment functioning increases.

Learn more about this solution

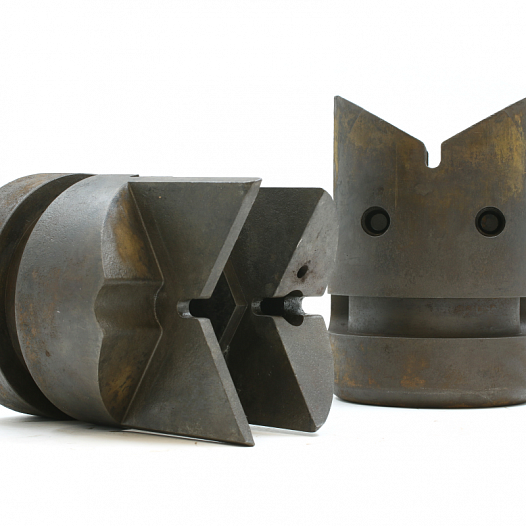

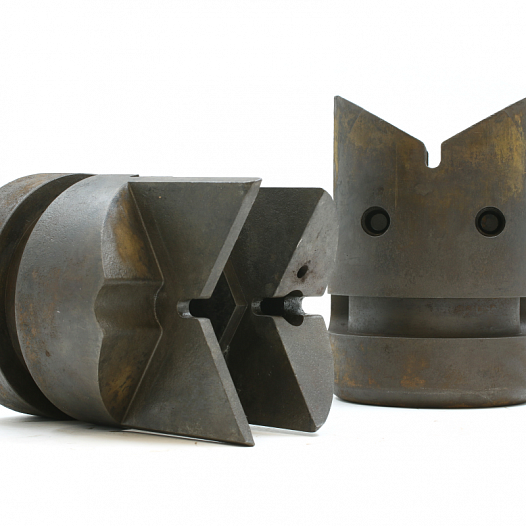

Gyratory crushers

Gyratory crushers

Before

After

To protect them from damaging, MODENGY 1003 anti-friction solid-film coating is applied onto the buttress threads of the gyratory crushers. It forms a steady lubricating separating layer that makes assembly and adjustment of the connections easier, excludes forming scuffing and galling.

Learn more about this solution

Soldering jaws of packing equipment

Soldering jaws of packing equipment

Before

After

To improve quality of weld seams on the polymer package, MODENGY 1007 anti-adhesive coating is used. It is applied onto the work surfaces of the soldering jaws contacting with the package to prevent melt polymer material from sticking, to reduce amount of defective items, and to extend service lifetime of the accessory.

Learn more about this solution

Ladles of the robotic system for collecting hard zinc

Ladles of the robotic system for collecting hard zinc

Before

After

In order to prevent hard zinc from sticking, MODENGY 1054 high-temperature anti-adhesive coating is applied onto the ladles. It retains its properties in the air gas-polluted with harmful vapours, and at melted drops falling, that is under conditions typical for a hot galvanizing line.

Learn more about this solution

Fasteners of marine equipment

Fasteners of marine equipment

Before

After

Protecting fastening items against corrosion under conditions of marine climate, making mounting easy, stabilizing screwing coefficient enable to improve reliability of equipment running.

Learn more about this solution

Meat dumplings apparatuses parts

Meat dumplings apparatuses parts

Before

After

To provide trouble-free running, a food grade anti-adhesive coating is applied onto the parts contacting with the dough. It prevents dough from sticking, and thus, improves quality of the finished products, and operational productivity of the meat dumplings apparatuses.

Learn more about this solution

Packaging equipment knife

Packaging equipment knife

Before

After

MODENGY 1007 anti-adhesive coating on the parts of the packaging machines serves as a barrier layer excluding direct contact between the knives and the melted polymer material. Due to this, package sticking-on and burning are prevented, work productivity of the equipment increased.

Learn more about this solution

Lead screws of drive mechanisms

Lead screws of drive mechanisms

Before

After

This product based on polytetrafluorethylene and molybdenum disulfide reduces friction in a screw-and-nut pair, makes parts moving easier, provided longterm corrosion protection.

Learn more about this solution

Cheese cutting knives

Cheese cutting knives

Before

After

At the Modengy Engineering Center, restoring of the worn separative coating on the equipment is done. A food grade anti-adhesive material is applied onto the parts contacting with food products.

Learn more about this solution

Cups edge-solderers

Cups edge-solderers

Before

After

To protect the edge-soldering devices against the sticking and burning film, MODENGY 1007 anti-adhesive coating is used. It has high heat-resistance (up to +350 °С), and requires no renewing over a long period.

Learn more about this solution

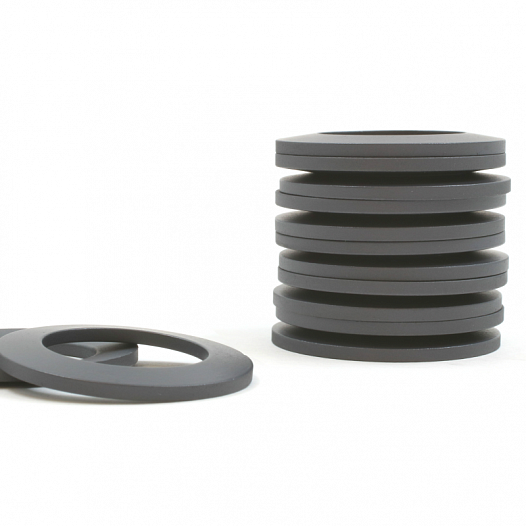

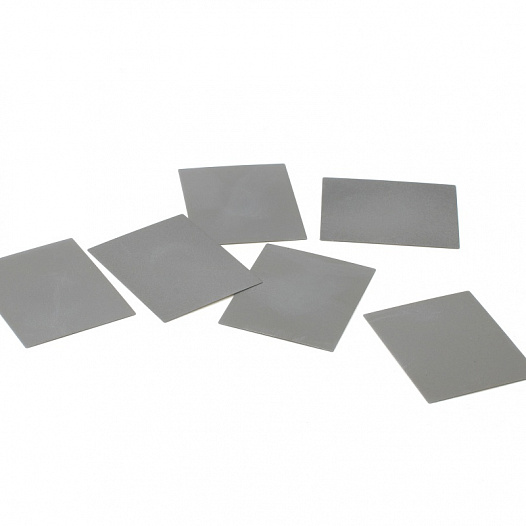

Disk springs

Disk springs

Before

After

To provide long and reliable springs operating, MODENGY 1014 anti-friction solid-film coating is used. It reduces friction of conjugated surfaces, protects against corrosion.

Learn more about this solution

Knives for parting chewing gum

Knives for parting chewing gum

Before

After

Food grade anti-adhesive coating is used to insulate the knife surface from contact with the chewing gum, and to prevent sticking.

Learn more about this solution

Pipeline valves parts

Pipeline valves parts

Before

After

To provide longterm protection for the pipeline valves parts functioning under conditions of exposure to chemically aggressive media, MODENGY 1014 anti-friction solid-film coating based on polytetrafluorethylene and molybdenum disulfide is used.

Learn more about this solution

Disk springs

Disk springs

Before

After

MODENGY 1014 coating has high chemical resistance, and excellent anticorrosive properties, due to which it provides long and effective disk springs protection against getting damaged.

Learn more about this solution

Spunbond edge-solderers rollers

Spunbond edge-solderers rollers

Before

After

MODENGY 1007 anti-adhesive coating is applied onto work surfaces of the edge-soldering rollers, and create a separative layer preventing polypropylene material from sticking. It has high heat resistance (+350 °С), and requires no renewing.

Learn more about this solution

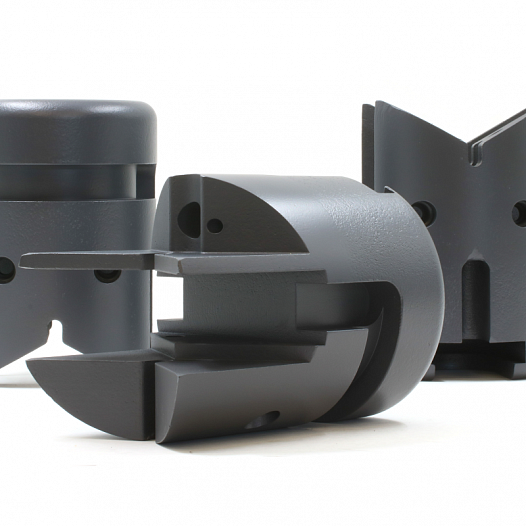

Preventor ram holders

Preventor ram holders

Before

After

A coatings system consisting of MODENGY 1005 and MODENGY 1014 is applied onto the preventor ram holders. The complex of these products protects the parts against impact of the aggressive media and corrosion, improves going smoothness, and provides reliable response of the equipment even after long downtime.

Learn more about this solution

Bushings of the wheel pump-up system

Bushings of the wheel pump-up system

Before

After

In order to prevent scuffing of the parts, MODENGY 1006 and MODENGY 1009 anti-friction solid-film coatings are used. They reduce friction in rotation process of the cuff, and thus prolong service lifetime, and operation reliability of the unit.

Learn more about this solution

Age gimlets

Age gimlets

Before

After

To make the gimlet entering into the wood easier, and to provide corrosion protection, MODENGY 1014 and MODENGY 1009 anti-friction solid-film coatings are applied onto the holder surfaces.

Learn more about this solution

Edge-solderers of plastic cups

Edge-solderers of plastic cups

Before

After

MODENGY 1007 coating is applied onto the operational surfaces of the cups edge-solderers to prevent melted packaging material from sticking. It has excellent anti-adhesive and anti-sticking properties, high heat resistance (up to +350 °С), resistance to washing-off, and to mechanical damages.

Learn more about this solution

Slide bearings of the motorbikes Enduro dampers

Slide bearings of the motorbikes Enduro dampers

Before

After

MODENGY For the ICE Parts coating creates a steady layer of dry lubrication on the bearings surfaces that minimizes friction in the mated parts, improves smoothness of going, and extends service lifetime of the dampers.

Learn more about this solution

Edge-soldering jaws for doy-packs

Edge-soldering jaws for doy-packs

Before

After

MODENGY 1007 and MODENGY 1014 have excellent separating, anti-adhesive, and anti-sticking properties. They create a smooth steady layer on the edge-soldering jaws that polymer material doesn’t stick to.

Learn more about this solution

Locking valves parts

Locking valves parts

Before

After

MODENGY 1014 chemically resistant coating is applied onto the internal surfaces of the locking valves parts. It reduces friction and wear, provides long-term protection for the components against aggressive media impact what has been proved by a number of climatic tests.

Learn more about this solution

Globe valve springs

Globe valve springs

Before

After

MODENGY 1014 forms a strong layer on the springs surfaces that insulate them from еру environment impact. Due to this, long corrosion protection for the parts is provided. High anti-corrosive properties of this product are proved by both the accelerated tests in the salt mist chamber according to ISO 9227 standard and the results of operating under real life conditions at aggressive media exposure.

Learn more about this solution

Edge-solderers for polyethylene film

Edge-solderers for polyethylene film

Before

After

MODENGY 1007 anti-adhesive coating forms a separating layer on the edge-solderers which the film doesn’t stick to. Due to this, trouble-free operating of the packaging line without necessity in cleaning the equipment from the stuck residues of the polymers is provided.

Learn more about this solution

Lead screws

Lead screws

Before

After

To provide long reliable operating of the transmission, MODENGY 1014 anti-friction solid-film coating is applied onto the lead screws. It provides service lubrication of the parts, prevents jamming, and scuffing forming, noise reducing in process of the lead screw moving, protects against corrosion, retains its operability under conditions of dustiness, minimizes possibility of equipment failure.

Learn more about this solution

Oil-extracting platforms fasteners

Oil-extracting platforms fasteners

Before

After

The set of a layer of the primer, and MODENGY 1014 anti-friction solid-film coating has high anti-corrosive properties what has been proved by the accelerated tests in the salt mist chamber (corrosion protection for more than 1,000 hours according to ISO 9227 standard). Besides, the system of these products makes mounting and dismantling of the connections easier, prevents scuffing forming on the thread turns, it doesn’t damage at transportation, and after longterm operating.

Learn more about this solution

Polyvinyl chloride film edge-solderers

Polyvinyl chloride film edge-solderers

Before

After

MODENGY 1007 coating provides trouble-free operating of the edge-soldering equipment, due to creating an anti-adhesive separating layer on the knives. The polyvinyl chloride film has no coherence with the coating, due to what its sticking is excluded.

Learn more about this solution

Edge-soldering plates

Edge-soldering plates

Before

After

MODENGY 1007 anti-adhesive coating forms a smooth separating layer on the surface of the edge-soldering plates which melted packaging material doesn’t stick to. It has long service term, and needs no refreshment for the hundreds operation cycles of the equipment.

Learn more about this solution

Edge-soldering elements

Edge-soldering elements

Before

After

This coating effectively operates at heating up to +350 °С, excludes direct contact between the materials to be weld together, and the edge-soldering elements preventing sticking-on and forming carbon deposits. Besides, MODENGY 1007 is resistant to washing off, and gives the edge-soldering devices aesthetic appearance.

Learn more about this solution

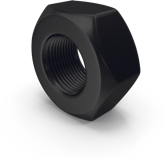

Union nuts and captive nuts

Union nuts and captive nuts

Before

After

MODENGY 1001 anti-friction solid-film coating forms a dry separating layer on the parts that excludes direct contact between the thread turns. Due to this, friction gets stable, mounting and dismantling of the connections makes easier, scuffing forming and thread galling are excluded, service lifetime of the nuts extends.

Learn more about this solution

Valve tappets

Valve tappets

Before

After

To extend service lifetime and reliability of the tappets operating, MODENGY 1006 anti-friction solid-film coating based on molybdenum disulfide and graphite is used. It is applied onto the supporting portion the parts, and contributes to reducing friction and wear.

Learn more about this solution

Edge-solderers of the packaging equipment

Edge-solderers of the packaging equipment

Before

After

MODENGY 1007 anti-adhesive coating is applied onto the edge-soldering elements of the packaging equipment to prevent polymer material from sticking to the working surfaces of the parts, and from forming carbon deposits. This product has long service lifetime, and operate great at high temperatures up to +350 °С.

Learn more about this solution

Soldering jaws

Soldering jaws

Before

After

MODENGY 1007 coating based on graphite operates at up to +350 °С. It forms a steady separating layer on the soldering elements that needs no refreshing during the entire service term of the equipment. Due to this, it gets possible to increase productivity of the works on producing files, and to improve quality of the finished products.

Learn more about this solution

Fasteners of offshore drill platforms

Fasteners of offshore drill platforms

Before

After

The fastening items to assemble equipment of the marine oil platforms mush have high corrosion resistance, and long service lifetime.

To provide the pointed features, MODENGY 1014 anti-friction solid-film coating is used.

Learn more about this solution

Wine barrels stands

Wine barrels stands

Before

After

Exhibit room elements besides having a long service lifetime must have aesthetic appearance. MODENGY 1010 anti-friction solid-film coating helps with providing these features.

Learn more about this solution

Variator for BOBST machine to produce package of corrugated cardboard

Variator for BOBST machine to produce package of corrugated cardboard

Before

After

MODENGY 1014 is applied onto the shaft neck, and MODENGY 1005 is done onto its mating part. Such combination of materials will enable to improve smoothness of variator disk going, and to reduce wear of the parts.

Learn more about this solution

Pump-compressor pipe clutches

Pump-compressor pipe clutches

Before

After

To extend service lifetime of the pump-compressor pipe clutches, MODENGY 1014 anti-friction solid-film coating is used. Due to its properties, it provides effective protection against corrosion and scuffing, prevents thread galling, makes mounting and dismantling of the connections easier.

Learn more about this solution

Springs for hydraulic fracturing equipment

Springs for hydraulic fracturing equipment

Before

After

For the purpose of extending service lifetime of the springs under conditions of contact with aggressive media, MODENGY 1014 chemically resistant coating is used. It isolates springs surface from impact of the destroying substances, and provides long trouble-free operation of the equipment.

Learn more about this solution

Shutting bushings

Shutting bushings

Before

After

MODENGY 1014 anti-friction solid-film coating is applied onto the surfaces of the shutting bushings of the oil-and-gas equipment contacting with the rubber seals.

This product based on polytetrafluorethylene and molybdenum disulfide prevents polymer elements from sticking to the metal parts.

Learn more about this solution

Conveyor belt shafts

Conveyor belt shafts

Before

After

To make belt moving easier, MODENGY 1009 and MODENGY 1014 anti-friction solid-film coatings are applied onto the shafts. Due to this, smoothness of the products moving along the conveyor improves, and wear of the parts in the metal-to-polymer pair reduces.

Learn more about this solution

Film edge-solderer

Film edge-solderer

Before

After

MODENGY 1007 coating having high separating and anti-sticking properties prevents direct contact, and film sticking onto the slabs surface without breaking heat exchange between the surfaces.

Learn more about this solution

Truck balance-beam bushings

Truck balance-beam bushings

Before

After

To reduce friction, and to extend service lifetime of the balance-beam bushings, MODENGY 1066 anti-friction solid-film coating is used. It has high load-carrying capacity, provides improvement of service term and operational reliability of the suspension.

Learn more about this solution

Moulds for silicone items production

Moulds for silicone items production

Before

After

MODENGY 1010 coating based on polytetrafluorethylene solve the issue of silicone sticking to the moulds. It forms a glossy separating layer making the process of taking the finished items out of the moulds easier.

Learn more about this solution

Slide guideways of the testing plant

Slide guideways of the testing plant

Before

After

MODENGY 1005 coating applying provides stable low friction coefficient of the slide guideways, improve smoothness of their moving, and reduces wear.

Learn more about this solution

Threaded connections of the control systems at NPP

Threaded connections of the control systems at NPP

Before

After

MODENGY 1066 coating enables to prevent threaded connections of the NPP diagnostics equipment elements from damaging. It makes mounting and dismantling of the connections easier, excludes jamming, extends service lifetime of the parts without need in refreshing.

Learn more about this solution

Hydraulic rams

Hydraulic rams

Before

After

The extend service lifetime of the hydraulic rams, MODENGY 1014 anti-friction solid-film coating is used. It reduces friction of the mated parts, provides corrosion protection, decreases starting effort of the hydraulic ram at temperatures below zero, prevents slip-stick motion, and significantly extends service life of the hydraulic cylinders.

Learn more about this solution

Throttle valves

Throttle valves

Before

After

Use of MODENGY Cleaner for throttle valve enables to remove all contaminations off the parts surface, and the anti-friction coating based on MoS2 increases tightness, reduces friction and wear of the contacting parts, improves sensitivity of the throttle valve, and prevents the elements from jamming.

Learn more about this solution

Molds for casting metals and alloys

Molds for casting metals and alloys

Before

After

To solve this issue of metal sticking to the molds, MODENGY anti-adhesive coatings are used. They make taking the items out of the molds easier, and reduce number of rejects. The suitable product is getting selected by taking into account the service temperatures upper limit.

Learn more about this solution

Soldering jaws

Soldering jaws

Before

After

Applying MODENGY 1007 anti-adhesive coating helps prevent polymer material sticking to the soldering jaws, and carbon deposits forming. The strong layer of the coating retain its operability at high temperatures (up to +350 °С), and requires no refreshing for the entire service term of the equipment.

Learn more about this solution

Moulds to produce gloves with latex covering

Moulds to produce gloves with latex covering

Before

After

To prevent latex sticking, MODENGY 1007 and MODENGY PTFE-A20 anti-adhesive coatings are applied onto the moulds. Use of these products provides long undisturbed operating of the line on producing gloves

Learn more about this solution

Pneumative gun frame and breech

Pneumative gun frame and breech

Before

After

In process of gun breech-block moving relative to the frame, severe friction arises between the parts leading to their premature wear.

To solve this issue, MODENGY 1066 and MODENGY 1001 anti-friction solid-film coatings are applied onto the pneumatic gun breech-block mechanism elements.

Learn more about this solution

Hunting carbine recharging mechanism

Hunting carbine recharging mechanism

Before

After

MODENGY 1066 anti-friction solid-film coating is applied onto breech frame and breech-block of the hunting carbine. A dry lubricating layer reduces friction and wear in excellent way under conditions of operating at heavy loads.

Learn more about this solution

Hot stamping drums

Hot stamping drums

Before

After

The hot stamping drums are used to apply a required pattern onto the terrace planks. When a hot shaft and a polymer surface are contacting, an issue of material sticking to the equipment arises.

To solve this issue MODENGY 1014 coating having anti-adhesive properties is used. Due to preventing polymer sticking continuous operating of the production line is provided, amount of defective products decreases, and service lifetime of the drums extends.

Learn more about this solution

Weapon recharging mechanism

Weapon recharging mechanism

Before

After

MODENGY 1066 anti-friction solid-film coating is applied onto the parts of the weapon recharging mechanism. It reduces friction between the frame and the breech block. Due to this, smoothness of going and moving speed of the parts increases, wear decreases, and reliability of the mechanism operation improves.

Learn more about this solution

Sewing machine presser feet

Sewing machine presser feet

Before

After

To reduce friction coefficient between the metal surface of the presser foot, and the leather material, MODENGY 1009 anti-friction solid-film coating is used. It provides easy presser foot sliding along the tissue without crumpling. Amount of defective products goes down, and sewing speed gets faster.

Learn more about this solution

Amphibious aircraft slide bushings

Amphibious aircraft slide bushings

Before

After

To extend service lifetime of the aircraft bushings, MODENGY 1066 anti-friction solid-film coating is applied onto them. It reduces friction and wear in the metal-to-metal pair, provides longterm corrosion protection.

Learn more about this solution

Diesel locomotives turbo-compressors bearings

Diesel locomotives turbo-compressors bearings

Before

After

Onto the surface of the diesel locomotive slide bearings MODENGY 1066 anti-friction solid coating based on molybdenum disulfide and graphite is applied. It effectively reduces friction, and extends service lifetime of the items.

Learn more about this solution

Shock absorber rods

Shock absorber rods

Before

After

To extend its service lifetime, MODENGY 1014 anti-friction solid-film coating is applied onto the rod. It reduces friction of the contacting parts, provides corrosion protection, improves smooth ness of going, and minimizes wear of the elements.

Learn more about this solution

Aero-engine pistons

Aero-engine pistons

Before

After

To extend service lifetime of the pistons, MODENGY 1003 and MODENGY 1007 anti-friction solid-film coatings are used. They reduce friction even at high loads onto the piston side surfaces while moving and changing its direction.

Learn more about this solution

Transmission jaw clutch

Transmission jaw clutch

Before

After

MODENGY 1005 anti-friction solid-film coating is applied onto operating surfaces of the clutches and gears to extend service lifetime of the mechnism. The resistant lubricating layer reduces friction between the contacting part, and prevents their wear.

Learn more about this solution

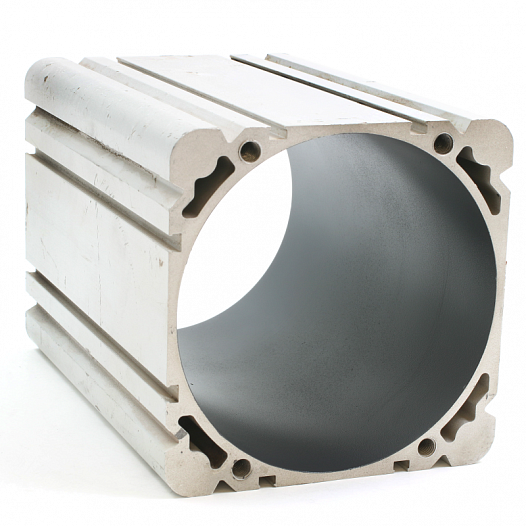

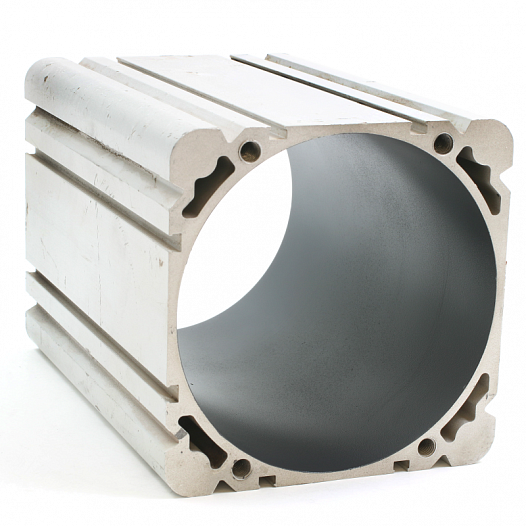

Pneumatic cylinders

Pneumatic cylinders

Before

After

To reduce friction, MODENGY 1014 anti-friction solid-film coating compatible with the seals materials is applied onto the internal surface of the pneumatic cylinders liners. It has high wear resistance, and extends service lifetime of the pneumatic cylinders even under aggressive operational conditions.

Learn more about this solution

Knives of the edge-soldering units

Knives of the edge-soldering units

Before

After

To cut film the edge-soldering units are equipped with knives. In process of operating the film sticks to them making following operating of the processing line harder. To solve this issue, MODENGY 1007 and MODENGY 1014 coatings having high anti-adhesive properties are applied onto the knives surface.

Learn more about this solution

Excavator sliding bearings

Excavator sliding bearings

Before

After

MODENGY 1005 based on molybdenum disulfide, and MODENGY 1066 based on composition of molybdenum disulfide and graphite, coatings withstand high loads even at small rotation speeds, have high separating and anti-corrosive properties. Due to these solid-film coatings, service lifetime of the bearings extends.

Learn more about this solution

Moulds to produce respirators

Moulds to produce respirators

Before

After

MODENGY 1007 anti-adhesive coating is used to prevent polypropylene preforms sticking to the moulds. This coating operated at -50 °С to +350 °С, and creates a resistant anti-sticking layer. Due to this, time costs for stopping and cleaning the equipment are excluded, continuous operating is provided, and productivity of the production line increases.

Learn more about this solution

Heating slabs of tunnel kilns

Heating slabs of tunnel kilns

Before

After

Waste products and other materials that are hard to remove, especially after long equipment operating, stick onto the slabs surface. To make cleaning the heating elements of the stuck components and carbon deposits easier, MODENGY 1014 anti-adhesive coating is used.

Learn more about this solution

Moulds for rubber items production

Moulds for rubber items production

Before

After

MODENGY 1014 anti-adhesive coating is applied onto the shape-forming surface of the mould for rubber goods production. Due to this, the issue of heated rubber sticking to the mould and its core in process of moulding is solved, carbon deposits forming is prevented, and service lifetime of the equipment is extended.

Learn more about this solution

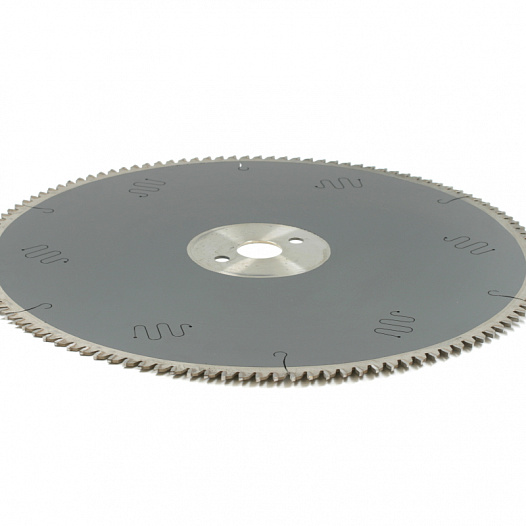

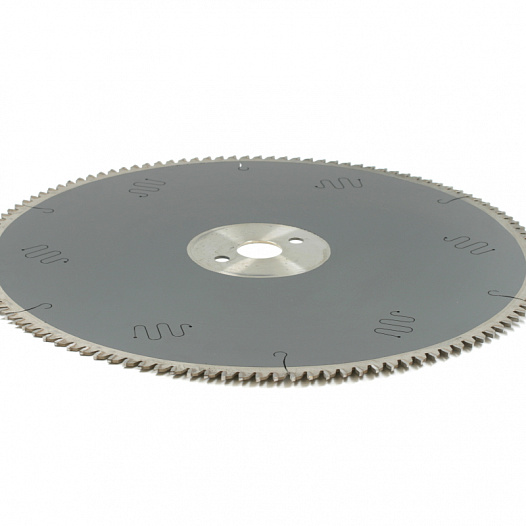

Saw disks

Saw disks

Before

After

To prevent polymer sticking MODENGY 1007 anti-adhesive coating is applied onto the saw blades surface. Single application of the product is enough to provide long trouble-free operating of the production line.

Learn more about this solution

Dissolvers screws

Dissolvers screws

Before

After

Producers of greases, adhesives, emulsions, and other multicomponent products face the issue of corrosion forming on the screws of dissolvers, the units to mi x substances. The rust particles got into the content of the finished products make them unusable.

To solve this issue MODENGY 1011 anti-friction solid-film coating based on polytetrafluorethylene onto the screws of the dissolvers.

Learn more about this solution

Moulds to produce items of raw rubber

Moulds to produce items of raw rubber

Before

After

In process of making the items of isoprene rubber, this material is sticking to the shape-forming mould surface, and as a result, carbon deposits forms, quality of the products get worse, and service lifetime of the accessories gets shorter.

To solve these issues MODENGY 1007 anti-adhesive coating is used. It prevents raw rubber sticking, and carbon deposits forming in the moulds sockets. Single applying of the product is enough to provide stable operating of the equipment for the entire period of its operating.

Learn more about this solution

Clamp mechanisms of steering racks

Clamp mechanisms of steering racks

Before

After

MODENGY For ICE Parts provides friction reduction, parts going smoothness improvement, components service lifetime extension. This coating reduces coefficient of static friction, and due to this stick-slip motion is prevented, and comfortable driving out for better alignment in the highway traffic is provided.

Learn more about this solution

Moulds for mouldings production

Moulds for mouldings production

Before

After

MODENGY 1009 and MODENGY 1014 coatings having anti-adhesive properties help prevent paste sticking to the operating surface of the moulds, decrease number of defective items in process of their production, extend service lifetime of the equipment.

Learn more about this solution

Soldering irons

Soldering irons

Before

After

Soldering irons are used to solder containers with food into polyethylene film. Because of film sticking to the operating surface of the iron, and carbon deposit forming, wholeness of the package might be broken.

MODENGY 1007 coating solves these problems forming a dry anti-adhesive layer on the soldering element surface which excludes polymer sticking onto the iron operational surface.

Learn more about this solution

Truck cranes telescopic booms

Truck cranes telescopic booms

Before

After

MODENGY PTFE-A20 coating based on polytetrafluorethylene forms an anti-friction layer on the surface having high load-carrying capacity. This coating is applied just single onto the boom sections, it has wide service temperature range (-50 … +130 °С), and high adhesion. While operating jointly with a grease, the coating reduces friction coefficient, prevents stick-slip motion, and protects against corrosion.

Learn more about this solution

Screws

Screws

Before

After

MODENGY 1007 and MODENGY 1014 anti-adhesive coatings form a strong anti-adhesive layer on the operating surfaces of the screws which hinders melted material to stick to the parts. Due to this, quality of the finished products improves, passing ability of the line grows, and service lifetime of the screws extends.

Learn more about this solution

Globe valves plugs

Globe valves plugs

Before

After

Producers of the pipeline fittings apply MODENGY 1066 coating with molybdenum disulfide and graphite onto the globe valves plugs. A thin lubricating layer reduces friction and wear as well as decreases force at the globe turning.

Learn more about this solution

Valve retarder rods

Valve retarder rods

Before

After

Applying MODENGY 1066 and MODENGY PTFE-A20 coatings onto the work surface of the rods reduces friction between them and the valve rubber seals. Due to this wear of the parts is prevented, and tightness of the units improves.

Learn more about this solution

Binocular thread

Binocular thread

Before

After

Binocular producers tend to provide smooth running of the parts, and to prevent their jamming at operating. For these purposes, MODENGY PTFE-A20 solid-film coating is used.

Learn more about this solution

Sun visor spring-hinge

Sun visor spring-hinge

Before

After

Our specialists have suggested applying MODENGY 1014 anti-friction coating onto the sun visor spring as an effective alternative of the conventional greases. The composition of this solid lubricant based on polytetrafluorethylene (PTFE), and a polymer binder enables to provide smooth and noiseless sun visor opening and closing during its entire service lifetime.

Learn more about this solution

End-soldering elements of packaging equipment

End-soldering elements of packaging equipment

Before

After

One of the main issues of operating the end-soldering elements of packaging equipment is polymer film sticking because of high temperature impact.

As a solution, MODENGY 1014 coating having anti-adhesive and antisticking properties is used. Single application of this product results in providing longterm protection for the end-soldering elements against film sticking and forming carbon deposits. Due to this, number of defective items reduces, and unscheduled stops of the packaging line to clean the equipment from the film residues are eliminated.

Learn more about this solution

Edge-soldering knives to produce plastic bags

Edge-soldering knives to produce plastic bags

Before

After

MODENGY 1007 on the edge-soldering knives of the machines to produce plastic bags eliminates the issue of polymer sticking onto the operational surface of the tools.

Learn more about this solution

Fastening parts for oil-and-gas equipment

Fastening parts for oil-and-gas equipment

Before

After

MODENGY 1014 anti-friction solid-film coating is applied onto the fastening parts for oil-and-gas equipment. It has high chemical resistance, and anti-corrosive properties.

In addition, MODENGY 1014 reduces friction in thread, prevents jamming, and scuffing forming, makes mounting of the connections easier, and extends their service lifetime.

Learn more about this solution

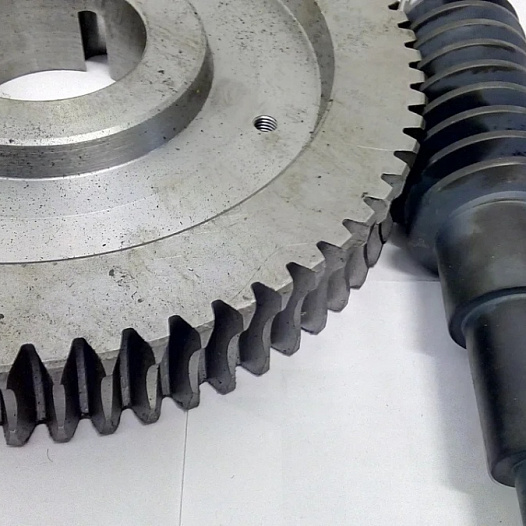

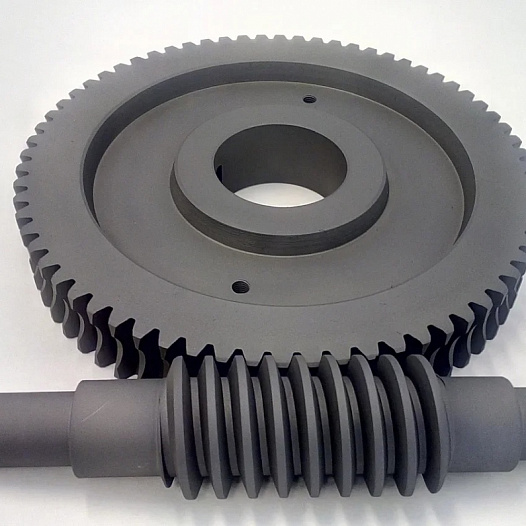

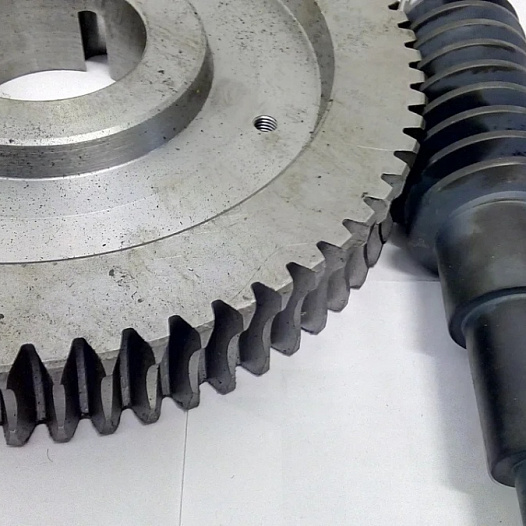

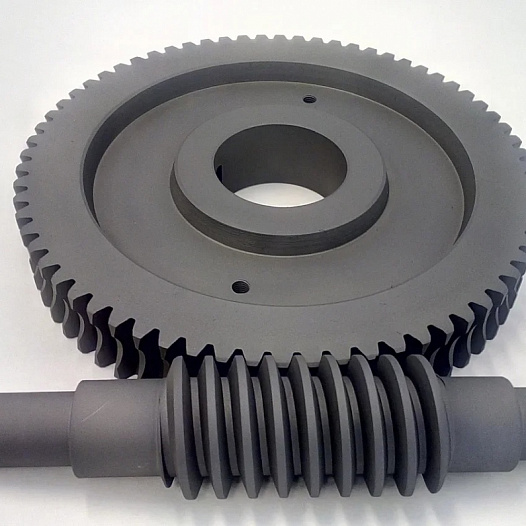

Reducer worm gears

Reducer worm gears

Before

After

To reduce friction, and to protect the elements against corrosion, MODENGY 1005 and MODENGY 1066 anti-friction solid-film coatings are used. They have high load-carrying capacity, wear resistance, operability in dusty environments, and long service lifetime.

Learn more about this solution

Pump-compressor pipe threads

Pump-compressor pipe threads

Before

After

MODENGY 1002 anti-friction solid-film coating extends service lifetime of pipe thread in absence of thread sealing paste, protects the parts against corrosion even while they are stored outdoors, prevents freezing-in of the protective cap under conditions the Far North.

Learn more about this solution

Pickers for capturing and transporting LPPE-containers

Pickers for capturing and transporting LPPE-containers

Before

After

Package producers do their best to not just make their products of good quality but also attractive in aesthetic way. Use of MODENGY 1007 on the pickers for capturing and transporting the bottles made of LPPE (low pressure polyethylene) contributes to providing these characteristics.

This coating prevents LPPE-containers sticking at the moments of taking them off the hot elements of the processing line, and moving forward along it.

Learn more about this solution

Reducers bearing rings

Reducers bearing rings

Before

After

MODENGY 1005 and MODENGY 1066 coatings based on graphite and molybdenum disulfide form an anti-friction layer on the surface of the rings having high load carrying capacity. It preserves the elements against premature wear due to reducing friction coefficient, and enables to considerably extend service lifetime of the reducers bearing rings.

Learn more about this solution

Car motor pistons

Car motor pistons

Before

After

To protect the pistons MODENGY 1007 anti-friction solid-film coating is used. It reduces friction of the mated parts under conditions of lubricating liquid lack, prevents scuffing forming, decreases noise from the motor’s side, and extends service lifetime of the components.

Learn more about this solution

Compressor pistons

Compressor pistons

Before

After

Use of MODENGY 1007 anti-friction solid-film coating on the pistons operational surface enables to make wear as minimum as possible, and to protect the parts against scuffing. This coating based on graphite withstands high loads, and is compatible with oils.

Learn more about this solution

Regulating valves of pipeline fittings

Regulating valves of pipeline fittings

Before

After

The regulating valve is an important element of the pipeline fittings. It serves to regulate the flows of various media at the enterprises of oil and gas complex. It is necessary to provide reliable and failure proof operation of the unit while transporting oil products.

For this purpose MODENGY 1014 coating is applied onto the valve elements. Due to anti-scuffing properties, it prevents galling of the threaded connections, and protects the parts against impact of aggressive media and corrosion due to its chemical resistance.

Learn more about this solution

End-soldering elements

End-soldering elements

Before

After

MODENGY 1007 is applied onto the end-soldering elements of the equipment for producing windows and door structures made of PVC. This coating creates a smooth anti-adhesive layer on the surfaces to be treated that prevents polymer sticking.

Learn more about this solution

Fasteners for ice-resistant fixed platforms

Fasteners for ice-resistant fixed platforms

Before

After

MODENGY 1014 coating protects the fastening fitting parts against corrosion, stabilizes friction, prevent thread galling at mounting and dismantling under conditions of temperature drops, and high humidity. Due to this, service lifetime and operation reliability of the equipment improve.

Learn more about this solution

Drives of power equipment

Drives of power equipment

Before

After

In order to extend service lifetime of the unit at operating under conditions of being exposed to the inert gas, the titanium bearing rings get applied with MODENGY 1006 based on molybdenum disulfide and graphite, and MODENGY 2560 based on tungsten disulfide and graphite coatings.

Learn more about this solution

Connecting branches of stainless steel

Connecting branches of stainless steel

Before

After

To make mounting-dismantling of the connections easier, and to prevent galling, MODENGY 1005 and MODENGY 1014 anti-friction solid-film coatings are applied onto the connecting branches. They have high anti-scuffing properties, reduce friction, and extend service lifetime of the fittings.

Learn more about this solution

Moulds for mechanical rubber goods production

Moulds for mechanical rubber goods production

Before

After

MODENGY 1007 anti-adhesive coating forms a resistant separating layer on the moulds which prevents rubber sticking to the metal surfaces. Due to this, taking the items out of the moulds gets easier, and amount of defective goods decreases.

Learn more about this solution

Tool for polymer pipes soldering

Tool for polymer pipes soldering

Before

After

MODENGY 1007 anti-adhesive coating forms a separating anti-sticking layer on the operating element that effectively prevents polymer sticking onto the equipment. This product operates at heating up to +350 °C, and requires no renewing.

Learn more about this solution

Conveyor rollers axes

Conveyor rollers axes

Before

After

To extend service life of the equipment they apply MODENGY 1014 anti-friction solid-film coating onto the axis slot. It creates resistant separating layer reducing friction in the rubber-to-metal pair as well as improves rollers motion smoothness.

Learn more about this solution

Spring block bushings and pins of the agricultural machinery

Spring block bushings and pins of the agricultural machinery

Before

After

MODENGY 1005 anti-friction solid-film coating having high load-carrying capacity and wear resistance is applied onto the bushings and pins of the agricultural machines. It reduces and stabilizes friction in the unit, improves smooth motion of the elements. Due to dry texture, this product effectively operates in dusted environment.

Learn more about this solution

Threaded connections of doubled hydraulic cylinders

Threaded connections of doubled hydraulic cylinders

Before

After

Elements of the doubled hydraulic cylinders are exposed to very high loads (tensile load reaches 35 tons). To prevent galling and sticking in such cases, MODENGY 1005 wear-resistance coating based on molybdenum disulfide is applied onto the external and internal threaded parts of the components.

Learn more about this solution

Edge-soldering knives

Edge-soldering knives

Before

After

To optimize the process of packaging, MODENGY 1007 anti-adhesive coating operating at +350 °С is applied onto the edge-soldering knives. Due to this, polymer material sticking is excluded, and service lifetime of the accessories is extended.

Learn more about this solution

Tray end-solderers

Tray end-solderers

Before

After

MODENGY 1007 anti-adhesive coating is used as a separating compound which prevents polymer sticking to the end-soldering elements, and reduces wear of equipment.

Learn more about this solution

Holders of the tools for beauty procedures

Holders of the tools for beauty procedures

Before

After

To protect aluminum holders of the tools against destructive impact of chemical aggressive media, MODENGY 1014 anti-friction solid-film coating is used. It also prevents scuffing from forming on the threaded parts of the components.

Learn more about this solution

Hydraulic hammer striking part

Hydraulic hammer striking part

Before

After

To extend service lifetime, MODENGY 1014 and MODENGY PTFE-А20 coatings having high lubricating and anticorrosive properties are applied onto the surface of the striking part.

Due to friction reduction, service lifetime of the polymer seals extends as well since because of their wear, the whole structure loses its tightness, and the unit have to be overhauled, and the specialty machinery has to stand idle.

Learn more about this solution

Parts of the laboratory facilities' supports

Parts of the laboratory facilities' supports

Before

After

MODENGY 1066 anti-friction solid-film coating is applied onto the thrust-bearings, hinges, and lids. It has high durable capacity, provides long-term lubrication, and corrosion protection. Use of this product enables to create a unit that requires no maintenance.

Learn more about this solution

Bicycle sprocket cassette

Bicycle sprocket cassette

Before

After

The purpose is – wear reduction, service life increase, protection against abrasive

Learn more about this solution

Adjusting bolts

Adjusting bolts

Before

After

MODENGY 1001 creates a thin film that eliminates danger of direct contact between the metal surfaces of the adjusting screw elements of stainless steel. It provides smooth and accurate adjusting of the equipment for a long while.

Learn more about this solution

Soldering jaws of packaging equipment

Soldering jaws of packaging equipment

Before

After

Steel jaws performing soldering of the laminated tubes function at heating up to +190 °С. In order to prevent melted material from sticking in process of forming a seam, MODENGY 1007 and MODENGY 1014 anti-adhesive coatings are applied onto working surface of the soldering elements.

Learn more about this solution

Restrictors of packaging thermo-shaping machines

Restrictors of packaging thermo-shaping machines

Before

After

MODENGY PTFE-A20 coating applied onto the restrictors, table tops, and other parts of the packaging devices provides smooth containers moving, and doesn’t dirty the finished products.

Learn more about this solution

Pistons of the truck engines

Pistons of the truck engines

Before

After

To extend service lifetime of the engine, MODENGY 1003 anti-friction solid-film coating is applied onto the piston skirts. Its wear-resistant separating layer prevents forming scuffing at overheating and extreme loads, makes cold start of the engine easier, and reduces friction of the mated parts under conditions of so called 'oil starving'.

Learn more about this solution

Steering hinges of automotive engineering

Steering hinges of automotive engineering

Before

After

To improve reliability and extend operation term of the steering hinge, producers apply MODENGY 1005 anti-friction solid-film coating having high anti-corrosive properties onto the rings and the ball pin. A smooth layer of the material provides friction reduction in the unit, makes process of assembling and disassembling easier, and extends its service lifetime.

Learn more about this solution

Intrawell equipment for hydraulic fracturing

Intrawell equipment for hydraulic fracturing

Before

After

MODENGY 1014 coating prevents chemical corrosion of the parts, provides their smooth going and reliability of operation as well as prevents sticking of asphalt-resin-paraffin deposits.

Learn more about this solution

Molds for shoe

Molds for shoe

Before

After

MODENGY 1007 anti-adhesive coating enables to refuse using silicone, and thus, to reduce prime price of the items and cut down time costs for equipment downtimes. A layer of the product prevents polymer sticking to the parts excluding necessity to clean them.

Learn more about this solution

Packaging equipment's end-solderers for the paper sanitary and hygienic items

Packaging equipment's end-solderers for the paper sanitary and hygienic items

Before

After

In order to optimize the process of packaging, MODENGY 1007 coating that his high anti-sticking and anti-adhesive properties, and operates at up to350 С is applied onto the end-soldering devices. Single applying of the product is enough to provide equipment long-term operating in regular mode.

Learn more about this solution

Agricultural machinery bushings

Agricultural machinery bushings

Before

After

The units and mechanisms of the agricultural machinery are subjected to high loads in process of operating. Particularly, the bushing-axle friction pair often functions under conditions of lubricating fluid lack, and as a result, it gets worn fast, and requires replacement.

To solve this issue MODENGY 1003 anti-friction solid-film coating is applied onto the internal surface of the bushing. It reduces friction and wear of the mated parts under conditions of oil starving, and thus extends service lifetime of the unit.

Learn more about this solution

Railway switch

Railway switch

Before

After

MODENGY 1005 and MODENGY 1014 coatings reduces friction and wear of the electric drive parts at 100% relative humidity, protects the elements against corrosion, and extends service lifetime of the railway switch mechanism.

Learn more about this solution

Scroll compressors

Scroll compressors

Before

After

MODENGY 1066 coating based on molybdenum disulfide and graphite has high values on wear resistance, and can operate at high contact pressures. This product reduces friction coefficient between spirals, and extends service lifetime of the unit. This solution enables to abandon using fluoroplastic, and is more practically feasible.

Learn more about this solution

Tool for soldering pipes’ polyethylene jacket

Tool for soldering pipes’ polyethylene jacket

Before

After

In order to prevent polymer from sticking to the tool, MODENGY 1007 anti-adhesive coating is used. It operates within temperature range of -50 С to +350 С, and provides a resistant anti-sticking coating that prevents sticking.

Learn more about this solution

Pressure sensor valve covers

Pressure sensor valve covers

Before

After