Home

Portfolio

Other industries

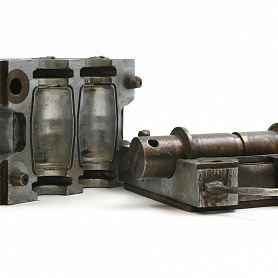

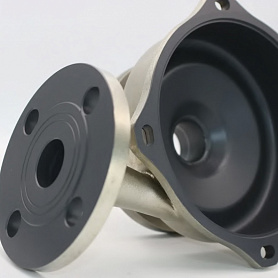

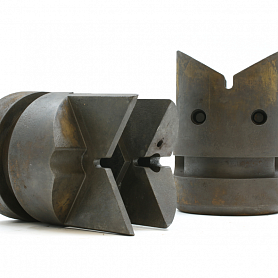

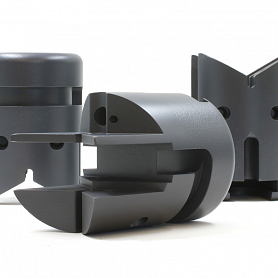

Variator for BOBST machine to produce package of corrugated cardboard

MODENGY 1014 / 1005

Variator for BOBST machine to produce package of corrugated cardboard

Image source:

shutterstock.com

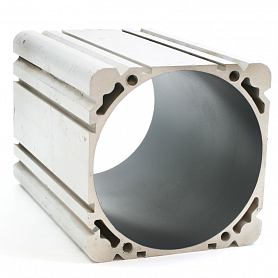

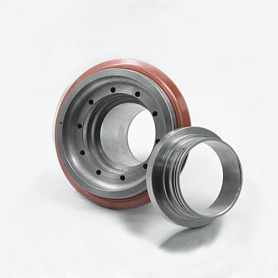

Because of high friction the variator disk of the machine to produce corrugated cardboard doesn’t slide well along the shaft neck surface. To solve this issue MODENGY 1005 and MODENGY 1014 anti-friction solid-film coatings are used.

MODENGY 1014 is applied onto the shaft neck, and MODENGY 1005 is done onto its mating part. Such combination of materials will enable to improve smoothness of variator disk going, and to reduce wear of the parts.

Video

The product used in this solution is

Other applications of materials

MODENGY 1014

MODENGY 1005

RU

RU

EN

EN