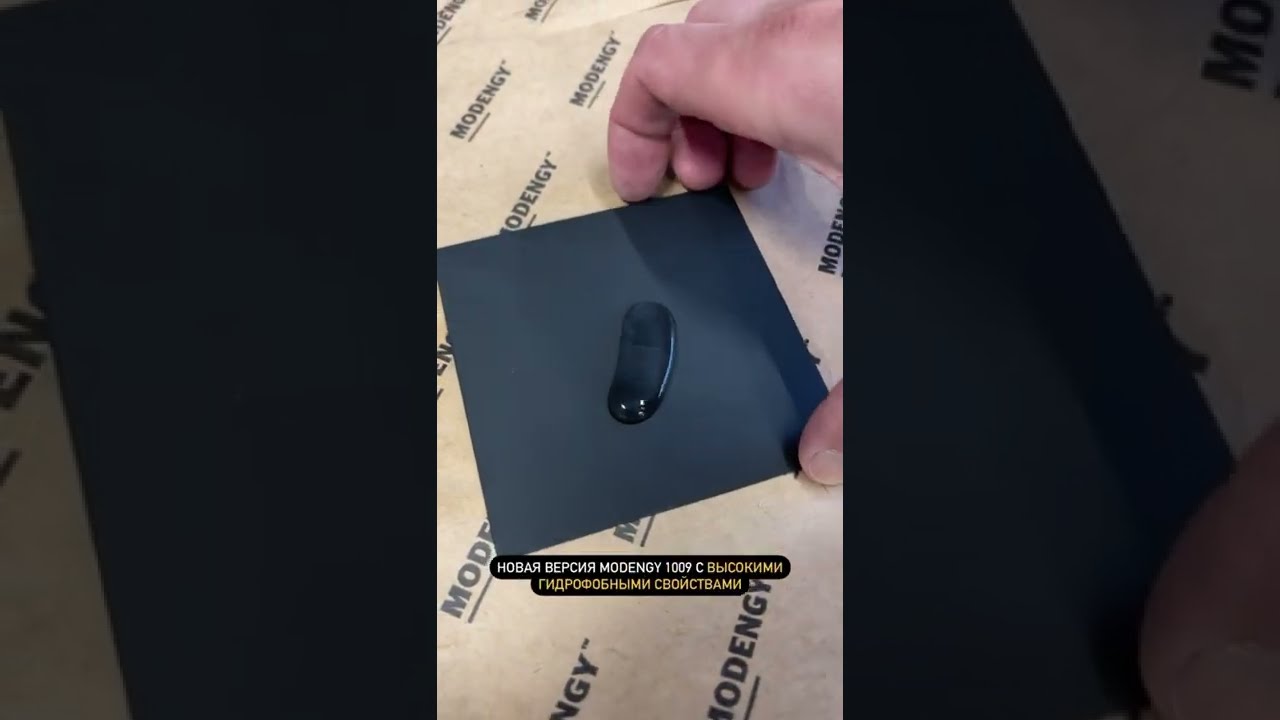

MODENGY 1009

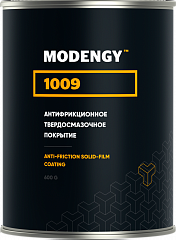

Sewing machine presser feet

Image source:

shutterstock.com

In process of sewing the items of leather material, the metal presser foot clamping the tissue doesn’t slide well enough along the leather surface. As a result of this, the leather tissue under the presser foot gets crumpled and wrinkled reducing stitch quality, and making operation speed slower.

To reduce friction coefficient between the metal surface of the presser foot, and the leather material, MODENGY 1009 anti-friction solid-film coating is used. It provides easy presser foot sliding along the tissue without crumpling. Amount of defective products goes down, and sewing speed gets faster.

To reduce friction coefficient between the metal surface of the presser foot, and the leather material, MODENGY 1009 anti-friction solid-film coating is used. It provides easy presser foot sliding along the tissue without crumpling. Amount of defective products goes down, and sewing speed gets faster.

RU

RU

EN

EN