Industrial enterprises face the necessity of moving loads every day. The perfect solution for this is mobile trolleys with wheels.

The basic parts of the wheel are a disk (the part’s body), a bearing to fix and to provide disk motions, and a bracket to fasten to the trolley.

The material used at their production is what the basic properties of the wheels depend on including the load they can withstand, heat resistance, ability to operate in aggressive media.

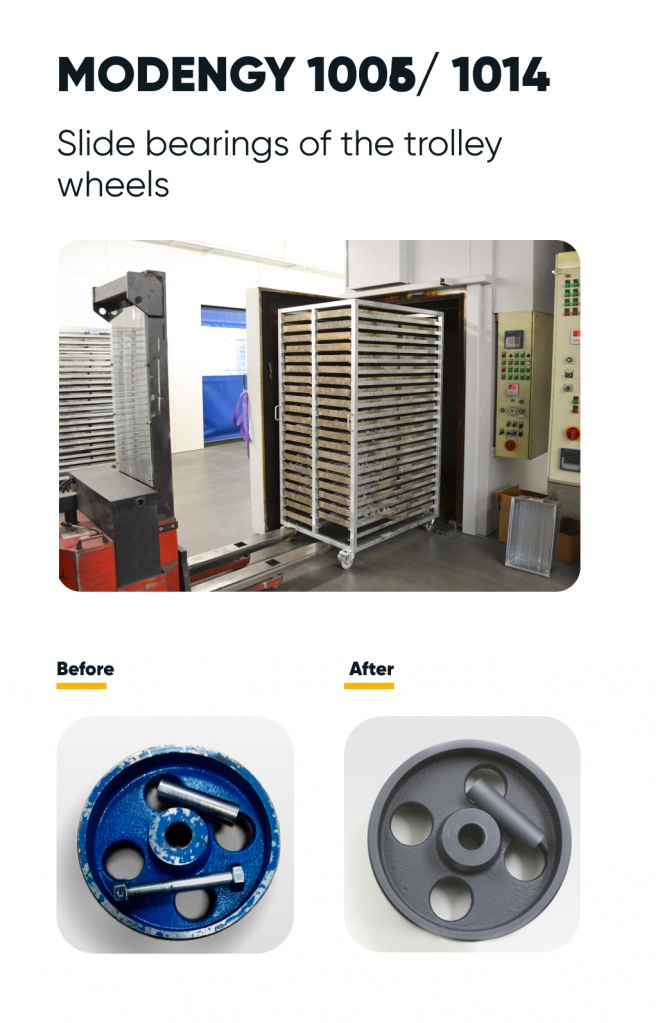

The cast-iron wheels are used for the trolleys of the high temperature drying kilns, the equipment for firing. For the purpose of providing wheel rotating the slide bearings are used.

The bearing bushing is subjected to scuffing in process of moving, and at operating under conditions of high temperatures wears strongly, gets stuck, and rusts.

Improving wear resistance of the industrial wheels bearings

To reduce friction and wear of the bearings, the conventional materials are often used: liquid lubricants and greases. However, they burn out and evaporate at heating, require frequent renewing, and are spent in a unthrifty way, attract dust and other abrasive particles into the mechanisms, which contribute to wearing the parts.

As more efficient solution MODENGY 1005 and MODENGY 1014 anti-friction solid-film coatings are applied onto the slide bearings of the trolley wheels operating at up to +255 °C. They create a wear resistant layer on the elements surface that contains particles of solid lubricant: polytetrafluorethylene, and molybdenum disulfide.

Advantages of using the coatings:

- Reducing and stabilizing friction coefficient of the mating parts

- Improving smooth wheel moving

- Eliminating squeaks and noises at moving

- Extending service lifetime of the equipment

- No harmful evaporates

- Single-time applying with no need in renewing

- Protecting metal elements against corrosion

- Operability in dusted environment - a dry layer doesn’t contribute to abrasive particles sticking onto the mechanism

- Resistance towards chemically aggressive media

These materials are applied by using a spraying gun. The coatings polymerize in a kiln at +200 °С within 40 minutes.

When it is necessary to maintain the wheels operating at heating at above +255 °С, the more heat resistant MODENGY coatings are used.

The Russian Modengy company provides services on applying their coatings at their engineer center located in Bryansk town.

For more detailed information, and consultation on solving the tasks related to reducing friction and wear contact the Modengy company, please

Request information

RU

RU

EN

EN