Anti-friction Solid-film Coatings Features

The anti-friction solid-film coatings are innovative lubricating materials that realize the dry lubrication principle. They form a protective layer of small thickness but high strength on the parts surfaces. It is a polymer matrix containing ultrafine particles of a solid lubricating substance.

The composition film formed as a result adheres strongly with the basis and provides excellent sliding reducing friction losses in such a way.

In Russia, the Modengy company releases such materials.

These products by the domestic manufacturer:

- Operate within a wide temperature range

- Demonstrate excellent antiscuffing and anticorrosive properties

- Withstand extreme loads

- Are resistant towards chemically aggressive media

MODENGY For ICE Parts Coating Performances

The material solid particles based on molybdenum disulfide and graphite penetrate into microcracks and rough areas of the part surfaces filling them in and lowering friction coefficient by this way. The composition also includes functional additives, an organic binding component, and a solvent.

As soon as the coating is applied, the solvent evaporates immediately. After that only a dry grey-and-black lubricating substance strongly adhered to the base remains.

MODENGY For ICE Parts provides the following:

- Stable operating in temperature range from -70 to +260 °С

- Reasonable consumpltion of 210 ml per m²

- Highly effective friction coefficient reduction

- Stick-slip motion and scuffing prevention

- Significant reduction of parts wear

- Resistance even under the highest loads and long lasting exposure to engine oils

- Long service lifetime

The Coating Application Fields

The coating is used in the following typical units:

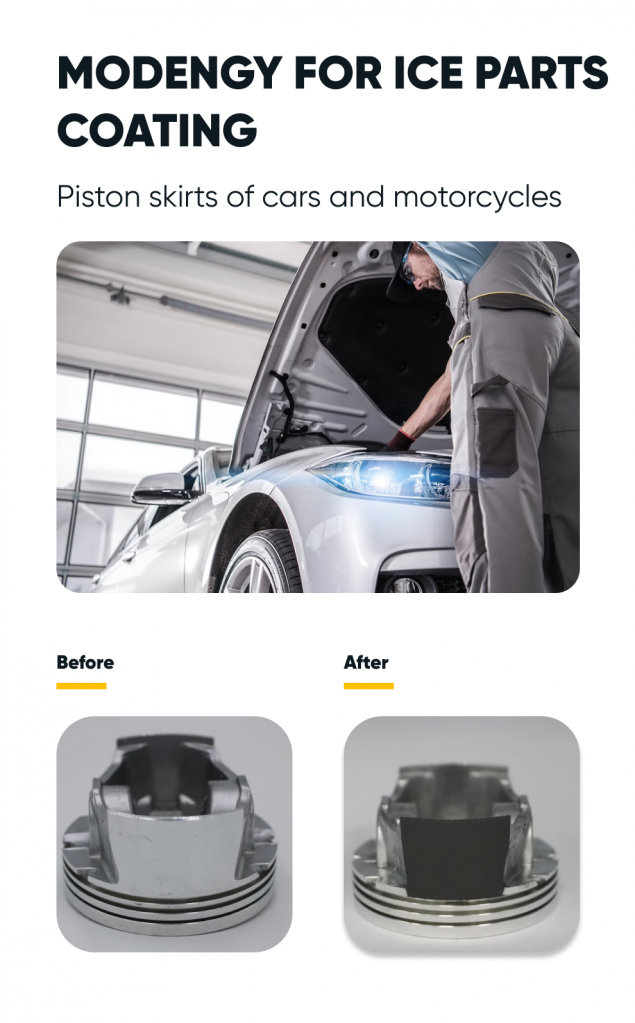

- Piston skirts

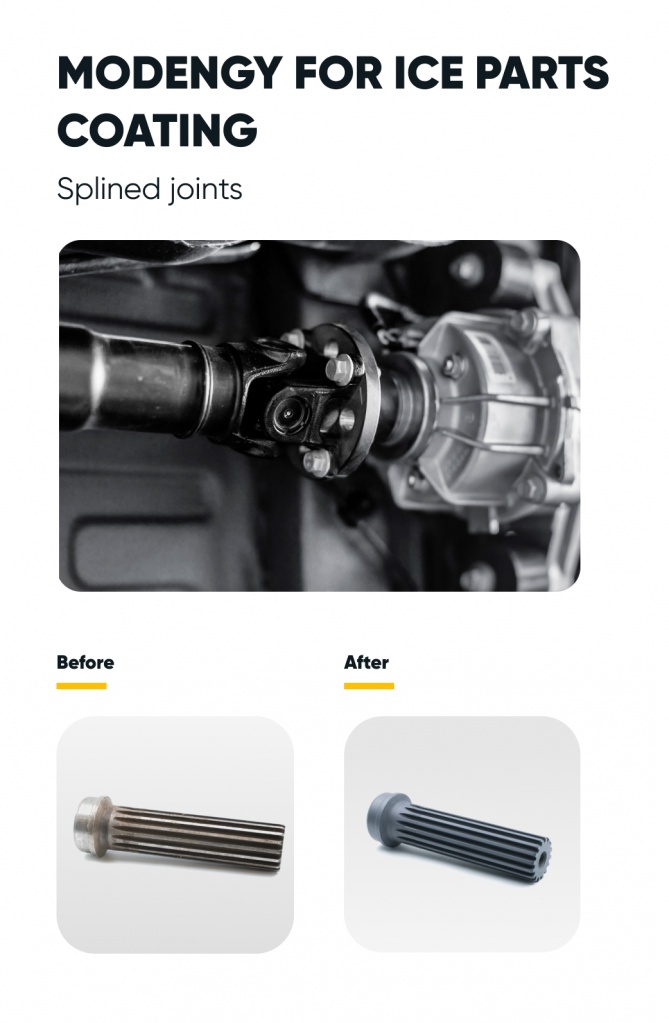

- Splined joints and threaded connections

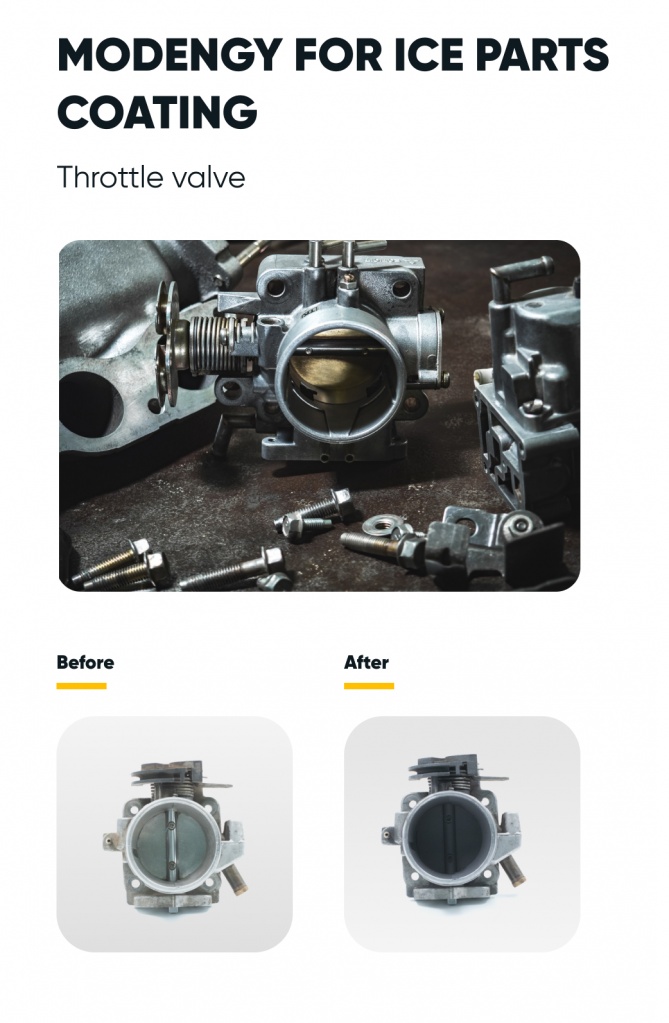

- Throttle valves

- Slide bearings

- Valve rods

- Other units with metal-to-metal friction pairs

Fig. 1. Throttle valve before and after applying MODENGY For ICE Parts coating

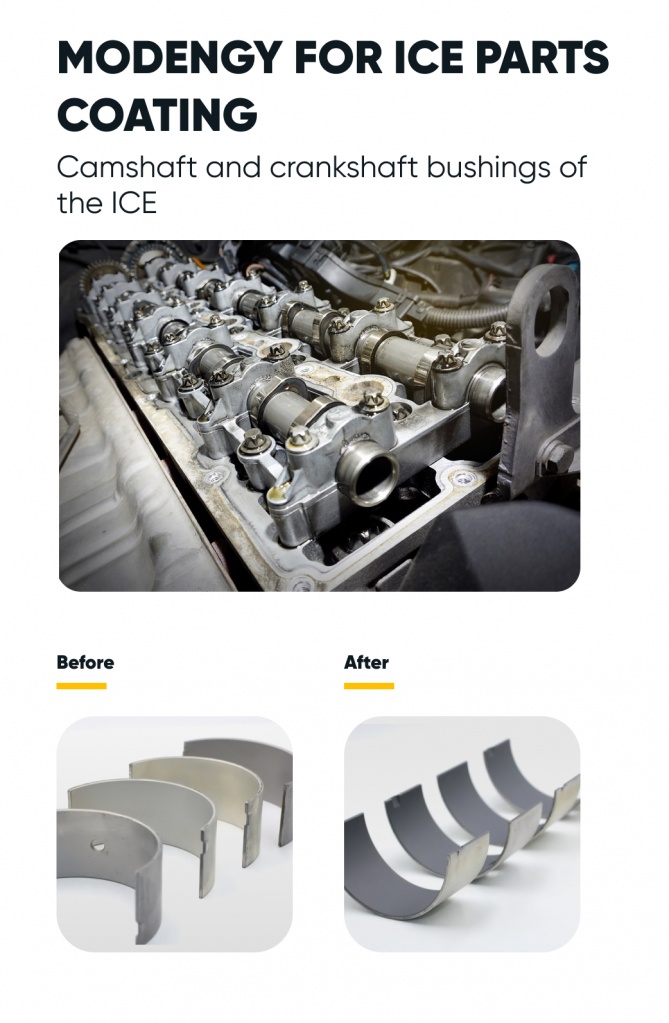

The coating is also applied onto the camshaft and crankshaft bushings of the ICE to reduce their wear, and to prevent various defects from arising. It retains its protective properties even under the most severe conditions of engine operation.

Fig. 2. Camshaft and crankshaft bushings of the ICE before and after applying MODENGY For ICE Parts coating

The product has also found application in industry at pistons production. The coating enables to extend service lifetime of the parts and the engine due to effective friction reduction and scuffing forming prevention. The agent is used on both new pistons and those under repairs.

Fig. 3. Piston skirts of cars and motorcycles before and after applying MODENGY For ICE Parts coating

Due to a good lubricating effect, MODENGY For ICE Parts provides smooth operation of the splined joints even at high contact pressures extending their service life by this way.

Fig. 4. Splined joints before and after applying MODENGY For ICE Parts coating

Instructions on how to apply

Prior applying the coating, some attentions should be paid to preparing the surfaces since this is the procedure that the product performance properties, and the adhesion force between the coating and the base depend on.First of all, the surfaces should be completely cleaned from the strongly adhered contaminations, and degreased with MODENGY Special Cleaner-Activator.

Next, applying process itself follows which is like this:

- The aerosol can with the product should be shaking for 3 minutes after little metal balls knocking sound appears

- The coating should be sprayed out by an uniform layer from the distance of 15 to 20 cm. Apply an additional layer of the agent over the dried first one if necessary

The Coating Testing Results

The anti-friction solid-film coatings of the domestic production for the interior combustion engine piston skirts have been tested as part of the state assignment on the import substitution program.The research were held with support of the Defense Ministry, and the Science and Higher Education Ministry of Russia at the tribology laboratory of the Institute of Mechanics Issues named by A. Ishlinsky in Moscow.

MODENGY For ICE Parts coating has demonstrated one of the best results.

The research has reveals that use of MODENGY For ICE Parts coating reduces friction losses by several times, enables to protect the piston skirts of the highly boosted diesel engines against damages and fast wear at heating, and the states of lacking motor oil, and when no enough lubrication is provided for the parts and friction units. Due to providing constantly low friction, service lifetime of the parts and mechanisms gets extended.

For more detailed information, and to get a consultation, please contact our experts.

Request information

RU

RU

EN

EN