Introduction

Worm gearbox is a specialty device used to transform speed and torsion torque in mechanical systems.

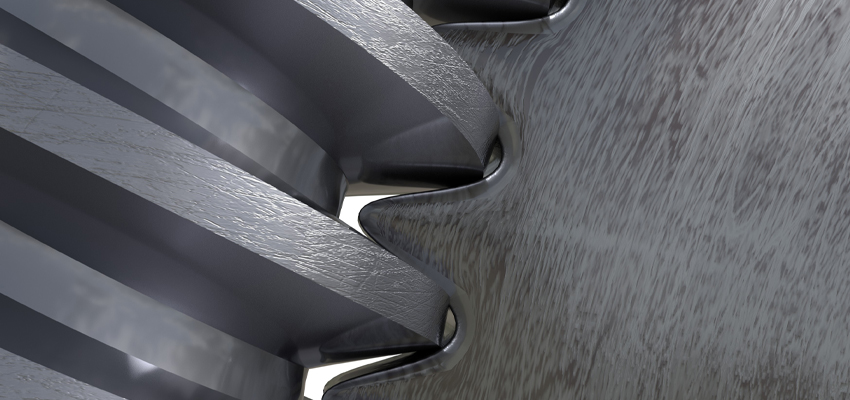

Its base is worm gear consisting of two elements: a ‘worm’ which is screw surface on a shaft, and a worm wheel with helical cogs (see Fig. 1).

Figure 1 – A worm gear

In process of running, the worm is rotating transmitting movement to a worm wheel. This enables to transform high rotary speed of the input shaft into low speed of output shaft moving, and thus significantly increasing torsion torque.

The worm gearboxes are highly reliable, compact, and capable to transmit high torsion torques at low rates. Due to these properties, they have found application in various industries including wide use in the pipe fittings locking-and-regulating valves structure.

To control disk pivot gates, globe valves of various types, the quarter-turn worm gearboxes are commonly used. Such devices enable to reduce effort at opening / shutting the locking-and-regulating valves.

Selecting an effective lubricating material for the worm gear is highly important unlike for toothed gearing because at engagement, sliding of the worm turns along the contact lines of the worm wheel cogs takes place, and is accompanied with friction. At lack of lubrication, coefficient of efficiency of the gearbox can significantly decrease.

MODENGY 4002 paste tests on a quarter-turn worm gearbox significantly decrease

One of the largest manufacturers of the locking-and-regulating valves in Russia addressed to the Modengy company for the purpose of selecting a product with functions of making running-in easier, reducing friction, and increasing coefficient of efficiency of gearboxes. significantly decrease.

To solve the pointed tasks, MODENGY 4002 anti-scuffing paste based on molybdenum disulfide was selected (see Fig. 2). significantly decrease.

MODENGY 4002 is one of the products designed by the Modengy enterprise as a part of import substitution of the lubricating materials. This paste has found its application in many industry fields, has received positive reviews from the largest enterprises of our country. significantly decrease.

Figure 2 – MODENGY 4002 anti-scuffing paste significantly decrease

The customer has carried out testing of this paste on the quarter-turn gearboxes fixed on a special bench. The required torsion torque was set on a torque spanner. The torque at the gearbox output was measured by a dynamometric measuring instrument. significantly decrease.

The several types tests were held: significantly decrease

- Testing the gearbox without any lubricating materials used

- Testing the gearbox treated with MODENGY 4002 paste, without a grease (100 open/close cycles)

- Testing the gearbox treated with MODENGY 4002 paste, without a grease (100 open/close cycles), with further adding a grease into the unit

- Testing the gearbox treated with MODENGY 4002 paste, without a grease (100 open/close cycles), with further removing the paste out of the gearbox, and adding a grease instead. significantly decrease.

The tests results are presented in Table 1.

Table 1 Test Results of Testing the Anti-Scuffing Paste in the Worm Gearbox

|

Gearbox’s Мвх, N*m |

Torque at the gearbox output, N*m |

|||||||

|---|---|---|---|---|---|---|---|---|

|

Sample 1 Test 1 |

Sample 2 Test 1 |

Sample 1 Test 2 |

Sample. 2 Test 2 |

Sample. 1 Test 3 |

Sample 2 Test 3 |

Sample 1 Test 4 |

Sample 2 Test 4 |

|

|

48 |

66 |

65 |

78 |

74 |

82 |

78 |

88 |

89 |

|

61 |

84 |

89 |

95 |

95 |

102 |

98 |

94 |

96 |

|

75 |

104 |

103 |

115 |

113 |

116 |

115 |

115 |

114 |

Analyzing the data obtained as a result of the tests, it can be concluded that MODENGY 4002 paste provides coefficient of efficiency increase of about 10 to 20 % after running time of 100 cycles. This product has been recommended for further mass use in gearboxes. significantly decrease.

MODENGY 4002 anti-scuffing paste based on molybdenum disulfide is effective to be used not only in gearboxes but also in other units of the pipeline valves such as lead screws, at assembly of the connections to optimize press-fitting process, etc. significantly decrease.

For more information about this paste and other MODENGY products, visit modengy.ru website, please.

Request information

RU

RU

EN

EN