TRENDS IN DESIGNING FRICTION UNITS

The manufacturers of various equipment face a number of complicated tasks and challenges in course of creating it such as high service temperatures, aggressive media effects, high contact pressures, preventing stick-slip motion and moving elements jamming, etc.

The following sustained tendencies have being watched at designing and producing modern machinery:

- Machinery dimensions decrease

- Moving elements motion speed increases

- Temperature range to be operated in gets wider

- It becomes possible to operate in chemically aggressive media

- Units that require no maintenance are created

- Electrical cars and robotics with specific requirements keep developing

- Safety for environment and human beings

APPLICATION ADVANTAGES OF MODENGY ANTI-FRICTION SOLID-FILM COATINGS

At the moment, many Russian and foreign equipment producers solve the tasks on reducing friction, wear, protection against corrosion and aggressive media by using MODENGY anti-friction solid-film coatings.

They are applied by the painting methods onto the parts surfaces of a wide range of constructive materials including metal, rubber, plastic, ceramics, wood, leather, glass and others.

MODENGY coatings are successfully used at the enterprises of the various industries both in Russian and abroad such as:

- Aerospace industry

- Automotive production

- Robotics

- Defense-industrial sector

- Oil-and-gas industry

- Hardware production

- Pipeline valves, compressors, and pumps production

- Electrical transport

- Nuclear power engineering

- Polymer items production

- Railway transport

- Agriculture machines production

- Lead screws and rods

- Slide bearings

- Threaded fasteners

- Gears

- Hydraulic and pneumatic cylinder liners

- Rubber seals

- ICE piston skirts

- Soldering elements of the packaging equipment

- Molds to cast polymers

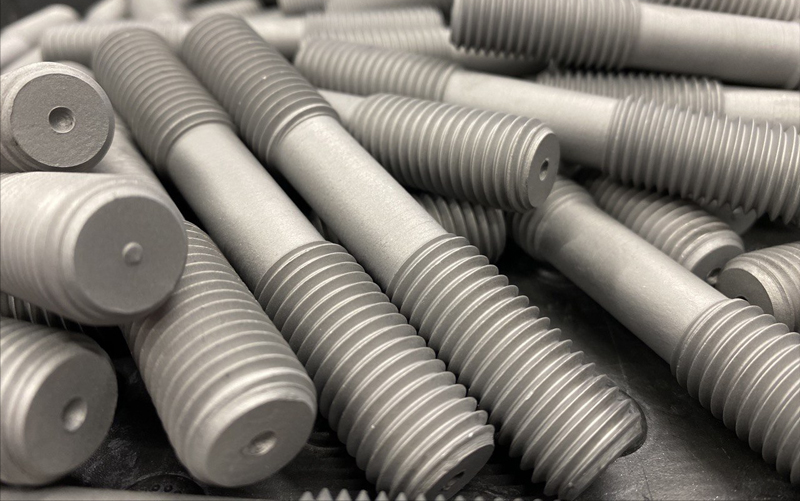

Fig.1. Parts covered with MODENGY coatings

Typical properties and advantages of MODENGY coatings:

- Wide service temperature range: -210...+500 °С

- Effectiveness in dusted environments – dry lubrication

- No evaporation or oxidation – they remain effective after long unit downtime

- High anticorrosive properties – they replace chromium plating and zinc plating

- Antiscuffing properties, and load carrying capacity up to 3,000 MPa – they are not squeezed out the contact areas

- They provide lubrication for the whole service lifetime of the mechanisms – friction units requiring no maintenance

- They influence little to the original part dimension – typical thickness of a coating layer makes 25 ± 5 µm

TARGET TRAINING ON HOW TO APPLY COATINGS FOR THE ENTERPRISE SPECIALISTS AT THE MODENGY TRAINING CENTRE

Many equipment manufacturers want to master technology of applying solid-film coatings at their plants by their own. For the purpose of contributing to this, the Training Centre (see Fig.2) has been created at the Modengy enterprise territory in Bryansk. More than 14 producing plants have successfully completed training over there for the last month.

Fig.2. The MODENGY Training Centre. Working process

At our Engineering Centre, the enterprises specialists get theory, and practical skills on how to apply the anti-friction solid-film coatings.

The training process is arranges so to use the real customer’s parts. Due to this, the specialists can practice and master all the stages of applying on them, and afterwards repeat the whole cycle of applying the coating at their enterprise.

THE MODENGY TRAINING CENTRE POSSIBILITIES

- Teaching the methods of analyzing initial quality of the part surface

At first, surface assessment on physical-and-mechanical, and micro-geometrical quality parameters is held. This is necessary to provide conformity with the requirements towards adhesion and service lifetime of the coating. According to the assessment results, the conclusions on the further optimal surface preparation are formed.

- Teaching the methods of preparing the part surface prior applying a coating

The chemical and mechanical methods of surface preparation are trained and practiced. They allow not only clean the surface from contaminations and oxide films but also form the optimal surface microrelief. The surface preparation strongly affects the coating adhesion quality, and its operational properties. So, we pay special attention to this stage at training. The specialists practice in preparing the part surface by using sandblasting treating (see. Fig.3), phosphating (see Fig.4), chemical etching of metals, and other methods (depending on a certain task, and initial surface quality). - Teaching how to apply anti-friction solid-film coatings

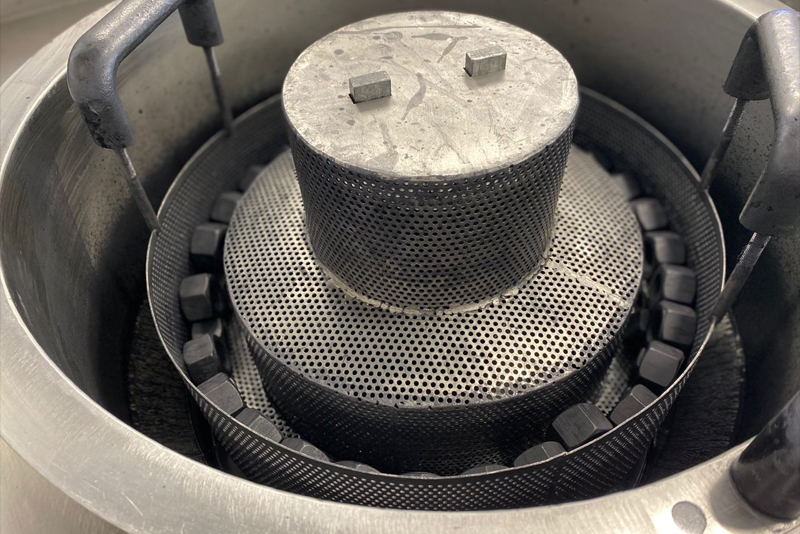

The skills on setting the specialty equipment for applying coatings are practiced and mastered (MODENGY M1-250 spray gun (see Fig.5), automated, and semi-automated MODENGY centrifuges (see Fig.6), and others).

The specialists practice and master the procedure of applying itself, modes of coatings drying and curing taking into account the part shape and dimensions, as well as location of the surfaces to be treated on it. - Teaching how to control quality

We teach the specialists how to hold quality control after applying the coating. The advanced precision apparatuses that allow detect the slightest declinations from the given characteristics are used to control surface quality.

Fig.3. The surface of the studs prepared by the sandblasting treatment method

Fig.4. The parts of aluminum before and after phosphating

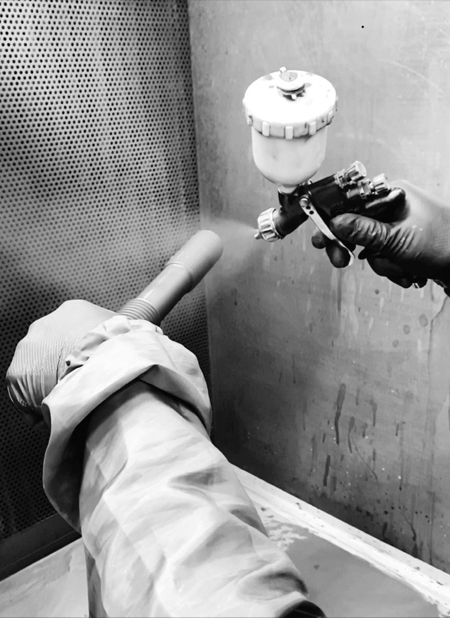

Fig.5. Applying MODENGY 1014 coating onto the studs by spraying method

Fig.6. Loading flange fastener into the centrifuge to apply the coating onto it

In the most cases, quality control is held by four parameters:

- Control of the layer thickness, and coating evenness

- Control of polymerization completeness

- Control of adhesion

- Check of operational properties

Our training course is intended for the engineers and service employees who are engaged in designing, producing, and maintaining various machinery. The training curriculum is developed and customized according to the purposes and tasks of each individual enterprise.

Fig.7. The specialists at training

To enroll for training on applying the anti-friction solid-film coatings, contact the Modengy company.

RU

RU

EN

EN