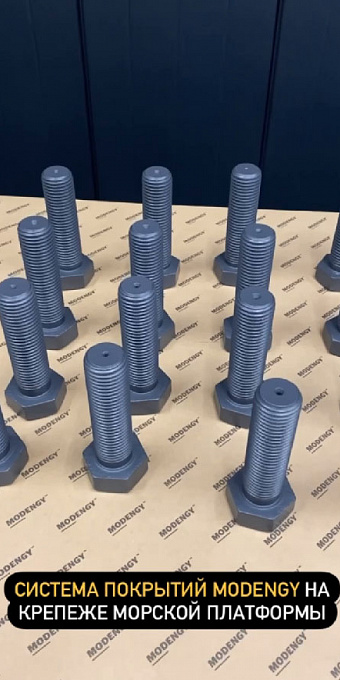

Fastener protection against corrosion

even under condition of aggressive environment

By using the coatings based on PTFE.

Friction and wear reduction

Corrosion protection

Request information

Efficient solution –

is

MODENGY protective solid-film coatings

Advantages of MODENGY coatings

based on PTFE

- Protecting fastener against corrosion for more than 720 hours according to results of accelerated test in salt mist on ISO 9227 Standard

- Preventing scuffing and thread ‘galling’ at multiple mounting/dismantling cycles

- Preventing contact corrosion

- Stable friction coefficient – providing quality tightening

- Wide service temperature range

- Aesthetical appearance

Typical issues at operating fasteners

Corrosion

Sticking

Scuffing forming, and thread galling

Difficulties with mounting / dismantling

Unstable friction coefficient

Environment pollution while using conventional thread greases

RU

RU

EN

EN