In this article from the collected theses from The Polykomtrib-2022 Conference (POLYKOMTRIB-2022: Theses of the reports of the international scientific-technical conference. – Gomel: MPSMI NSA of Belarus, 2022. – 107 p.), the research results of MODENGY anti-friction coatings based on molybdenum disulfide in vacuum at heating up to +250 °C, and under regular operational conditions are presented. The researches were held by the scientific oficers of the Machine Science Institute named after A.Blagonravov of the Russian Science Academy (MSI RSA), and the Nacional Research University of the Moscow State Technical University named after N.Bauman (NRU MSTU).

Introduction

The solid lubricating coatings based on molybdenum disulfide with various binders demonstrate high efficiency at operating under space condition. They have good binding and protective functions, reduce wear, improve reliability of operating, and extend service lifetime of the units and mechanisms [1,2].

Solid-lubricating coating is a liquid substance formed after applying a dry anti-friction 20±5 µm thick layer.

The friction units of the equipment operating in space are exposed to high and low temperatures, radiation, vacuum. In the presented paper, the extreme conditions are high temperature, and vacuum.

The aim of the given paper is to detect friction coefficient of the anti-friction coatings based on molybdenum disulfide under regular, and extreme conditions.

Materials and Methods

In the given paper, 5 samples of the coatings based on molybdenum disulfide and polytetrafluorethylene that are known under the following trademarks: Coating B is MODENGY 1053; Coating C is MODENGY 1014; Coating F is MODENGY 1002; Coating H is MODENGY 1005; Coating K is MODENGY 1006 are researched [3]. The introduced coatings variants are different by composition including the binder type, level of the tribotechnical and anti-corrosive properties as well as cure type (cold, or hot).

Coating application technology includes the following stages:

- Microsandblasting, cleaning, and surface activating

- Applying the coating by spraying method

- Surface curing

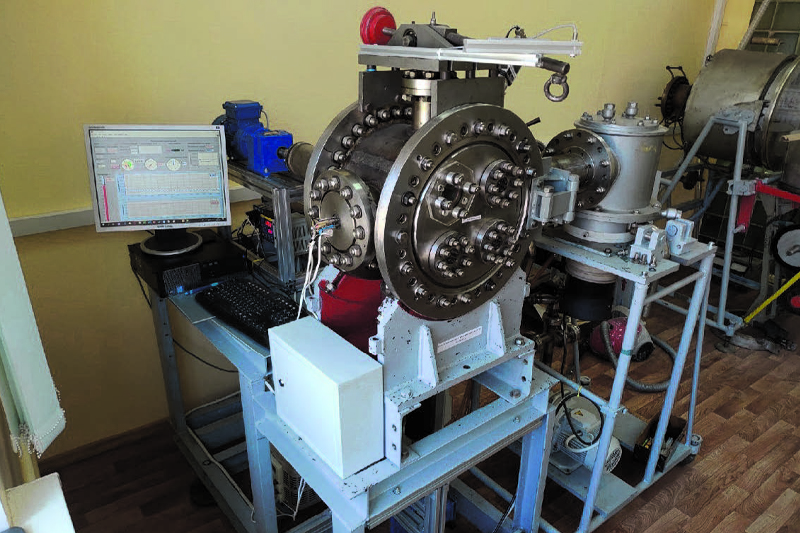

BC-01 tribological vacuum stand was used to hold the experiments [4].

Fig. 1. BC-01 tribological vacuum stand

The tests on detecting friction coefficient were held in vacuum at pressure below 10–4 Pa, and at +250 ℃.

Tribological tests were held in accordance with ASTM G133 Standard (tests for friction at reciprocal motion) on the ‘ball-along-flat’ scheme. The little ball material is SHKH15 steel, its diameter is 6.35 mm.

The stand is equipped with an analog-digital controller, a vacuum meter, resistance strain gauge to measure friction force, and a thermocouple.

Results, and discussion

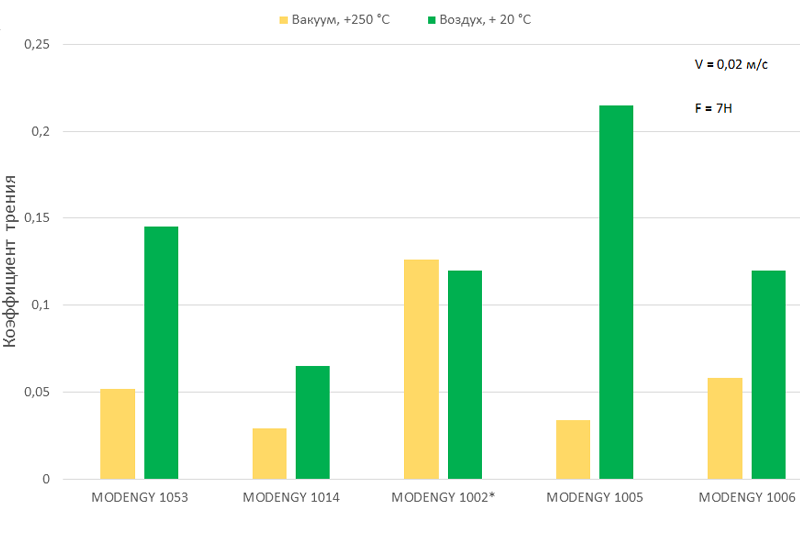

In process of the experiment friction coefficient values were gained for each sample that are presented below (see Fig. 2).

Fig. 2. Friction coefficient average values in vacuum, and in air at +250 °C, and +20 °C, respectively

*acc. one experiment results, repeated tests are required

The research results in vacuum at pressure below 10-4 Pa, and at +250 ℃ have demonstrated that Coating C sample has the least friction coefficient equal to 0.029. This sample contains polytetrafluorethylene in addition to molybdenum disulfide.

Friction coefficient of Coating F sample in vacuum is equal to 0.126, the value that exceeds friction coefficient values of the rest of the samples by 2 times. Friction coefficient values of Coatings B, H, and K samples are equal to 0.052, 0.034, and 0.058, respectively.

Friction coefficients of all samples are much higher in air than in vacuum (except Coating F sample). The reason of this is moisture negative effect on molybdenum disulfide.

1. Wang, H., Xu, B., Liu, J. (2012). Solid Lubrication Materials. In: Micro and Nano Sulfide Solid Lubrication. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-23102-5_1

2. K.V.Gavrilov, A.V.Morozov, M.V.Seleznev, Yu.V.Rozhdestvensky, N.A.Khozenyuk, A.A.Doikin, V.S.Khudyakov. Friction and Wear. 2020. V. 41. No.5, p. 647-654.

3. Modengy. MODENGY is the coatings to reduce friction: [website]. URL: https://modengy.ru/about/ (enquiry is May,19th, 2022).

4. M.V.Prozhega, E.O.Reshchikov, A.D.Shirshov, N.G.Yakovenko. Frictional properties of polymers for 3D-printing at friction in vacuum // Friction and Wear. – 2020 (41), No.6, p. 760-767.

RU

RU

EN

EN