The anti-friction solid-film coatings based on polytetrafluoroethylene (PTFE) have proven for a long while to be effective means for corrosion protection, and friction reduction in various units. However, special equipment is required to apply these materials what creates certain inconveniences, especially while under field conditions.

Knowing about this, the Engineers of the Russian Modengy company have developed MODENGY PTFE-А20, a PTFE-based coating in the aerosol can. It is easy to apply, and cures fast at room temperature.

Coating description and its typical features

MODENGY PTFE-A20 allows to form a 10 to 25 µm thick composite layer on the parts surface. From the chemical point of view, it is a polymer matrix with the ultrafine PTFE particles in its cells.

The coating, firmly coherent to the base, has high compression resistance and low shear resistance. Due to this, the dry friction coefficient on the treated surfaces makes just only a few hundredths.

An aerosol can with MODENGY PTFE-A20 coating has a nozzle with accurately set spraying parameters, so that to provide quality applying of the agent.

To get be better adhesion of the coating, MODENDY Special Cleaner-Activator is used (see Fig.1). It cleans, degreases, and activate the surface, and then evaporates without leaving any traces.

Fig. 1. MODENGY PTFE-A20 and MODENGY Special Cleaner-Activator

MODENGY PTFE-A20 coating operates within -50 to +130°С temperature range, protects against corrosion for at least 168 hours (accelerated test in salt mist according to ISO 9227 Standard). Material polymerization occurs at +20 °С within 30 minutes.

MODENGY PTFE-A20 Advantages

The main advantages of MODENGY PTFE-A20 coating are:

- Low friction coefficient

- High anticorrosive properties

- Effectiveness in dusty environments (the coating realizes the ‘dry’ lubrication technology)

- Ability to prevent stick-slip motion

- Anti-adhesive properties (the compound prevents sticking and improves sliding)

- Translucence (the coating doesn’t spoil parts’ appearance)

- Compatibility with metal-metal, metal-rubber, metal-plastic, plastic-rubber friction pairs

Application Procedure

To get quality coating follow these instructions.

First, remove strongly adhered contamination off the surfaces (such as carbon deposits, residues of the previous coatings, greases, etc.). For this purpose use any mechanical or chemical methods available.

After that treat the items with MODENGY Special Cleaner-Activator. This procedure can be done repeated several times if it's necessary with in-between breaks to dry the parts. Don’t touch the parts surfaces with your hands!

Before applying MODENGY PTFE-A20 coating, shake the aerosol can thoroughly. In order to get the content mixed well enough you should keep shaking the can for at least 3 minutes more after you hear tapping of little balls inside it.

Spray out the coating as a thin even layer from the distance of 15 to 20 cm. In 5 to 10 minutes, when the part turns matte in appearance and dry by touch, you can apply the second layer.

As soon as complete your work, make sure to clean the spraying head nozzle. For this purpose turn the aerosol can bottom up and in the opposite direction from yourself. Then push the spraying button and hold it until the nozzle starts emitting pure gas.

The coating fully cures within 30 minutes at room temperature. As a result, an off-white translucent layer is formed on the parts which will protect them against wear.

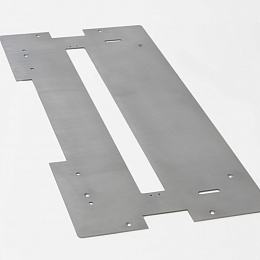

See the video instructions on coating application on example of treating the brake pad pressure plates.

Application examples

MODENGY PTFE-A20 is used to protect against corrosion and reduce friction in the fitting running mechanisms.

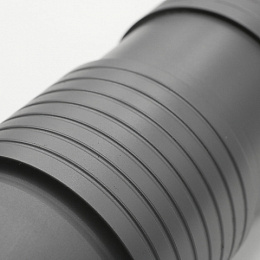

The coating prevents sticking the rubber seals to the cylinder liner in the pneumatic drives, eliminates stick-slip motion effect, and extends service lifetime of the devices in general.

In the disk pivot gates, the compound is applied onto the case elements which are in contact with the disk sealing (see Fig.2).

Fig. 2. MODENGY PTFE-A20 coating application in the disk pivot gate

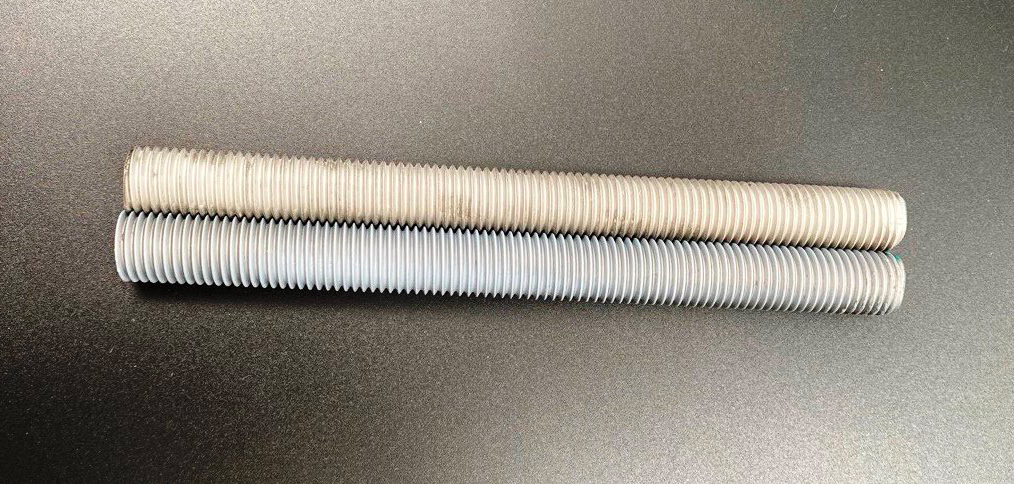

In the globe valves with movable saddles, MODENGY PTFE-A20 protects the body against corrosion and makes saddles motion easier. The coating is also used in the threaded fastener: it prevents galling in the thread at its mounting-dismantling, and provides it with additional anticorrosion protection (see Fig. 3).

Fig. 3. An element of the threaded fastener before (above) and after (below) the treatment.

In the packaging equipment, MODENGY PTFE-A20 is used as anti-adhesive agent that improves sliding of the packaging machines' collar surfaces. As a result, it becomes possible to prevent sticking the packaging film to them.

The coating is used to decrease wear of some automotive parts, sliding door elements, furniture, and office equipment. It reduces friction in sliding guideways of the wood- and metalworking machines, textile industry equipment.

When applied onto the moving elements of the gas pressure regulator shutter, MODENGY PTFE-A20 solve the issue of galvanic couple forming. At the same time, it prevents souring of the friction unit, losing its mobility, and device failing.

RU

RU

EN

EN