MODENGY PTFE-A20

Anti-friction solid-film coating based on polytetrafluorethylene (PTFE)

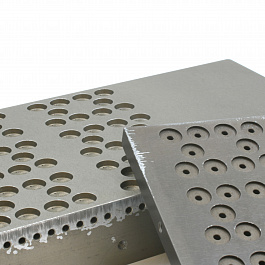

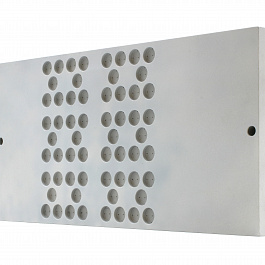

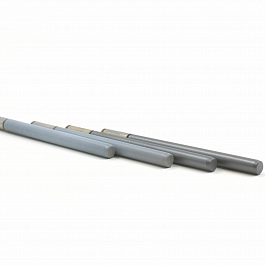

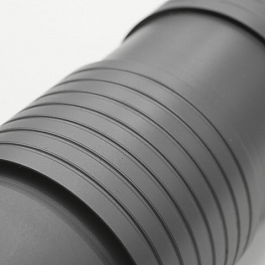

It is used in the sealing devices of the pipeline fittings as an anti-adhesion agent that prevents sticking, and improves sliding. It is applied onto the car interior parts, sliding doors parts, furniture hinges, office equipment components, sliding guides of the machine tools in woodworking, and metal processing, in textile industry, in the packaging equipment units and parts (protection against sticking packaging material).

Package sizes:

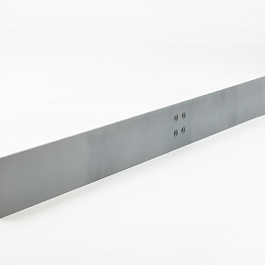

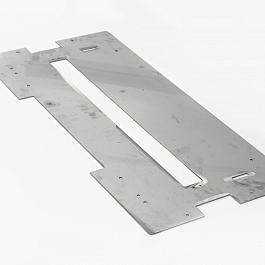

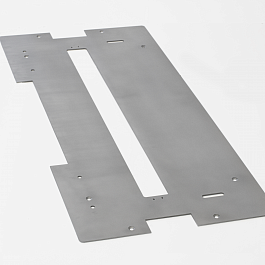

MODENGY PTFE-A20 in action

Additional expendable materials

and equipment

- MODENGY Special Cleaner-Activator is intended to clean, degrease, and activate surfaces

- MODENGY 1013 Special Solvent to rinse the equipment after the coating is applied, to remove uncured coating

- MODENGY M1-250 Spray gun - to apply MODENGY anti-friction solid-film coatings

Advantages

- Fast cure at room temperature

- High anticorrosive properties (> 168 hours, according to the results of the sped tests in salt mist)

- It prevents stick-slip motion and squeak

- Wide service temperature range

- Low friction coefficient

- It prevents sticking-on dust and abrasive particles

- Translucent coating doesn’t spoil parts appearance

- It makes parts assembly by the robots faster

- Non-toxic after complete cure

Specifications

- Colour: white translucent

- Service temperatures range: -50 … +130 °С

- Corrosion protection: > 168 hours (ISO 9227)

- Standard coating consumption: 60 g / m²

- Curing temperature / time: +20 °C / 30 min

Applying the coating by your own

Use to prepare and clean the surface. Only it guarantees good adhesion

Keep shaking the aerosol can with the coating for at least 3 minutes after you hear tapping of a little ball inside it

Spray the coating from the aerosol can onto the surface to be treated from the distance of 20 to 30 cm

Let the coating dry for at least 10 min. at room temperature until opacity appears (it’s the interim air-drying stage)

Apply the second layer of the coating over the dried previous one, if necessary

Let the coating dry for at least 30 minutes at room temperature (it’s the final air-drying stage)

RU

RU

EN

EN