Introduction

Strict requirements are imposed towards threaded fasteners that are used in critical structures and equipment. Reliability of their functioning depends on the ways of protecting the fastening items while their friction features affect the quality of the joint tightening at a given tension force. In flange joints, uneven tightening causes joint deformation and loss of tightness.

Under complex operational conditions (such as aggressive climate, corrosively active environment, frequent dismantling of the connection, or, on the contrary, long downtime) as well as at using the fasteners made of alloyed steels, many conventional solutions get ineffective.

One of the modern and effective ways to provide long and reliable operating of the parts under complex operational modes, easy mounting and dismantling, low and stable torsion coefficient, long corrosion protection is using special coatings for fastener (see Fig.1).

Figure 1 – Parts of the pipe fitting adjusting valves treated with MODENGY 1014

Functions of MODENGY coating for fasteners

The Russian Modengy company (Bryansk town) has designed anti-friction solid-film coatings for fastening parts for various purposes (see Fig.2).

The coatings have high anti-friction and anti-corrosive properties, chemical resistance, resistance towards washing-off, anti-scuffing properties, heat resistance. A thin layer of the coating (20 micrometers) is not squeezed out of the contact zone even at high loads, and doesn’t pollute the environment.

Figure 2 – MODENGY coatings for fasteners

MODENGY coatings for fasteners are made on base of solid lubricating materials such as molybdenum disulfide, graphite, polytetrafluorethylene, etc. These substances get integrated into the friction surface by using binding resins, that is film-formers.

The coatings are applied onto the fasteners by painting methods including spraying out, or dipping with centrifuging. After they have cured, a uniform layer of solid lubricant forms on the parts that is a matrix of a binder with the solid-lubricating substances particles distributed all over its cells.

MODENGY coatings are used on fasteners for the purpose of:

- Protecting against corrosion

- Reducing and stabilizing torsion coefficient

- Preventing sticking-on, jamming, galling

- Providing possibility for multiple mounting-dismantling with keeping wholeness of the lubrication layer

- Protecting against chemically aggressive substances

In order to extend service lifetime of fastener, both certain coatings separately, and MODENGY coatings systems are used. They consist of two layers: base and top. Combination of coatings enables to enforce certain properties, or provide new features that these materials don’t have separately.

Review of MODENGY solutions for fastening items

MODENGY coatings are used for fasteners for different purpose. Depending on the work conditions used at producing constructive materials items, and other paraments, certain MODENGY coating products can be applied.

As a part of import substitution, MODENGY 1032 anti-friction solid-film coating based on polytetrafluorethylene has been designed by the Modengy enterprise for one of the largest fasteners manufacturers in Russia.

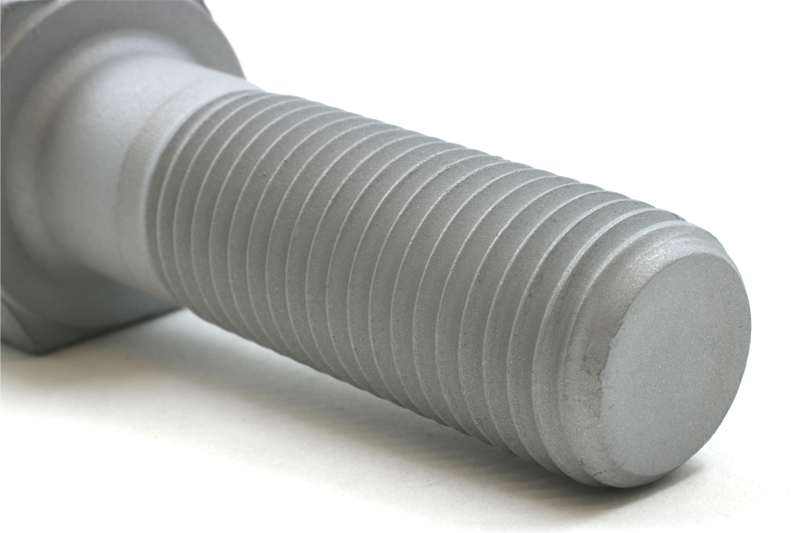

This coating is applied in complex with a base zinc lamel layer, and it serves to reduce and stabilize torsion coefficient of the fasteners. The coatings system based on MODENGY 1032 (see Fig.3) has great anti-corrosive properties – not less than 900 hours in neutral salt mist according to ISO 9227. If necessary, this factor is possible to increase by changing the recipe.

Figure 3 – Fastener of construction metal structures treated with the coatings system based on MODENGY 1032

The coatings system based on MODENGY 1032 has high elasticity, and spalling resistance, ability to adapt to outline of the mating part, resistance to sedimentation (suspended particles are not deposited in large process tanks), provides low and stable torsion coefficient.

Taking MODENGY 1032 as a base has made it possible to create protective systems of coatings for high-strength fasteners which enable to control torsion coefficient within a wide range.

This product of silver colour has favorable cost, and it is optimized to be applied by the methos of dipping with centrifuging at fasteners mass production.

For fasteners made of stainless steel, the issue of galling is relevant. Due to the features of this structural material, higher friction that causes heating and plastic deformation of the thread turns is observed in the contact zone at assembly.

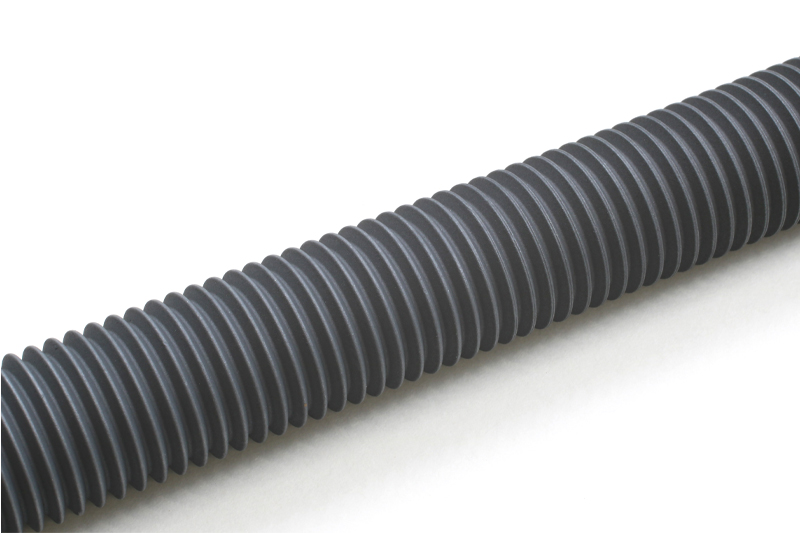

MODENGY 1001 coating based on molybdenum disulfide and graphite provides effective protection for fasteners against scuffing, sticking, and galling. It forms a thin separating lubrication layer on the surfaces that prevents the thread turns from contact and seizure (see Fig.4).

Figure 4 – Thread treated with MODENGY 1001 solid-film coating

MODENGY 1001 has the widest temperature range among all MODENGY coatings for fasteners: -180 to +440 °С.

This product is convenient to be used at a mounting site as MODENGY 1001 is available to be purchased even in aerosol cans, and no exposure to high temperatures is required for it to cure.

MODENGY 1002 coating based on molybdenum disulfide is be notable for its great anti-corrosive properties (160 hours according to results of the accelerated tests in neutral salt mist according to ISO 9227 standard), due to what it has acquired as an effective way to protect fastener and threaded connections made of black steels. Besides, it gets cured at room temperature, and is available in aerosol cans form.

MODENGY 1002 retains its operability at -210 до +320 °С, can be used in combination with threaded greases.

MODENGY 1076 + MODENGY 1014 coatings system (see Fig.5) is intended for the fasteners operated under very aggressive conditions (such as corrosively active environments, high humidity and temperature, multiple mounting-dismantling of the connection without possibility to renew the coating).

MODENGY 1076 is a protective coating having high anti-corrosive properties (more than 720 hours according to ISO 9227). However, the anti-friction features of this product are minimal. This coating is used as a base layer as a part of the coatings system based on MODENGY 1014.

MODENGY 1014 is anti-friction solid-film coating based on molybdenum disulfide and polytetrafluorethylene that has low friction coefficient, high chemical resistance, and elasticity. It is used to protect the fasteners operated at aggressive media exposure. It has demonstrated excellent results at accelerated tests in the neutral salt mist chamber according to the international ISO 9227 standard: more than 672 hours.

Figure 5 – Fasteners of the marine oil platforms treated with the coating system based MODENGY 1014

The system of these coatings has unique protective and anti-friction properties. Even when top layer is damaged while careless mounting, it retains its high resistance to corrosion – more than 1000 hours according to ISO 9227.

Conclusion

The product line of MODENGY anti-friction solid-film coatings includes the coatings providing reliable and longterm operating of the fastening items under most complex modes of operation.

At the present time, the Modengy company is actively engaged with import substitution of lubricating materials for Russian production enterprises – on a customer's technical specification, a new lubricating compound (a coating, a paste, a dry adaptive lubricating material, etc.) can be developed. For more detailed information, address the Modengy company, please.

For more detailed information, address to our experts by clicking the button below.

Request information

RU

RU

EN

EN