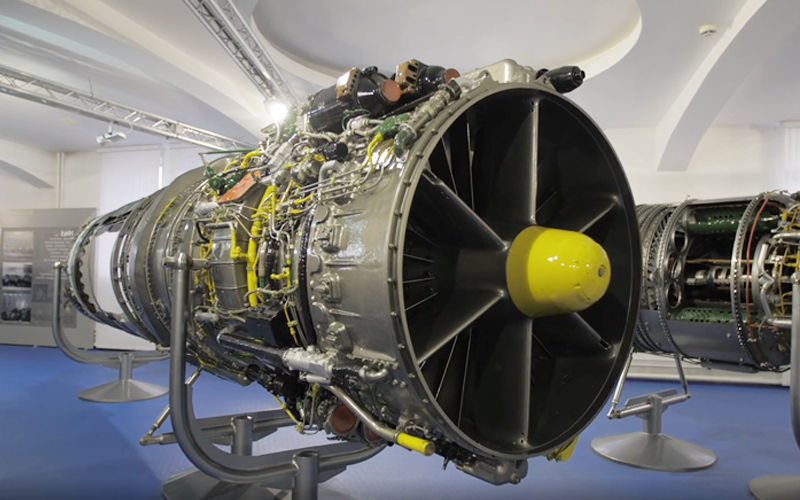

Turbine purpose and structure

Turbines are the major part of the equipment to generate power and heat. They are used as power generator drive at various type power stations, transport, compressor units.

A turbine is a rotor with radially located petals. One more row of the different shape lobes is set on the body but remains motionless while operating – it’s a stator. A pair of one rotating element and one motionless one is called a turbine stage.

Power generating by a generator happens due to feeding combustion products into it by the rotating under pressure turbine lobes. Kinetic energy of the expanded gases flow transforms and creates mechanical energy of rotor rotating.

Energy turbines differ on the incoming working medium that is the substance through which energy transformation is realized with. For the turbines, it is steam or gas. There are gas, steam, and steam-gas plants.

Turbine construction prospects in Russia

Heat power stations (HPS) in Russia use both gas and steam turbines. They were always purchased abroad: delivered already ready to be operated or installed under a foreign license.

The rights for these units belonged to the foreign companies what made process of using them and disposing them complicated.

At the moment a new program has been developed in Russia according to which a quarter of all energy units should be replaced for the domestic ones.

A great breakthrough has been already reached in this direction: the first GTD-110M gas turbine of entirely Russian production has been assembled.

It has passed testing based on results of which it has been proved that this turbine doesn’t give way to the imported analogs by its productivity – 5,700 hours of running time. By its dimensions and weight, the domestic unit is almost half smaller.

The next stage is mass production of turbines. The planned performance makes 2 items a year. Opportunities for going out to the world market are under developing.

Import substitution policy

The domestic scientific developments become a guarantor of the country stability in the field of production technologies. The new turbine development be called a part of the strategy on development the own industry.

Production of the entirely Russian energy turbines will give positive effects including:

- Creating the new jobs

- Economic benefits - mass production of the units will make less than paying for the foreign turbines, transporting expenses, and maintenance. According to the experts’ calculation, use of the domestic units will cut down the capital costs by 30 percent while maintenance expenses will do by 50 percent.

- Shortening the supply terms for HPS

- After home demand has been satisfied, an opportunity to compete to the world companies at the foreign market will appear

Extending service lifetime of the energy turbines by using domestic coatings

The energy turbines are powerful highly productive plants. Their friction units and parts are exposed to extreme loads and temperatures (500 to 600 °C).

For the purpose of improving reliability and extending service life of the turbine equipment elements and mechanisms, it is necessary to implement innovative lubricating materials.

As a part of the import submission program, the materials of Russia production only which meet all technical requirement are allowed to be use on the new turbines.

The Modengy company located in Bryansk town release such products. The MODENGY brand anti-friction solid-film coatings (AFSFCs) have been created to function for a long while in the heavily loaded units and mechanisms.

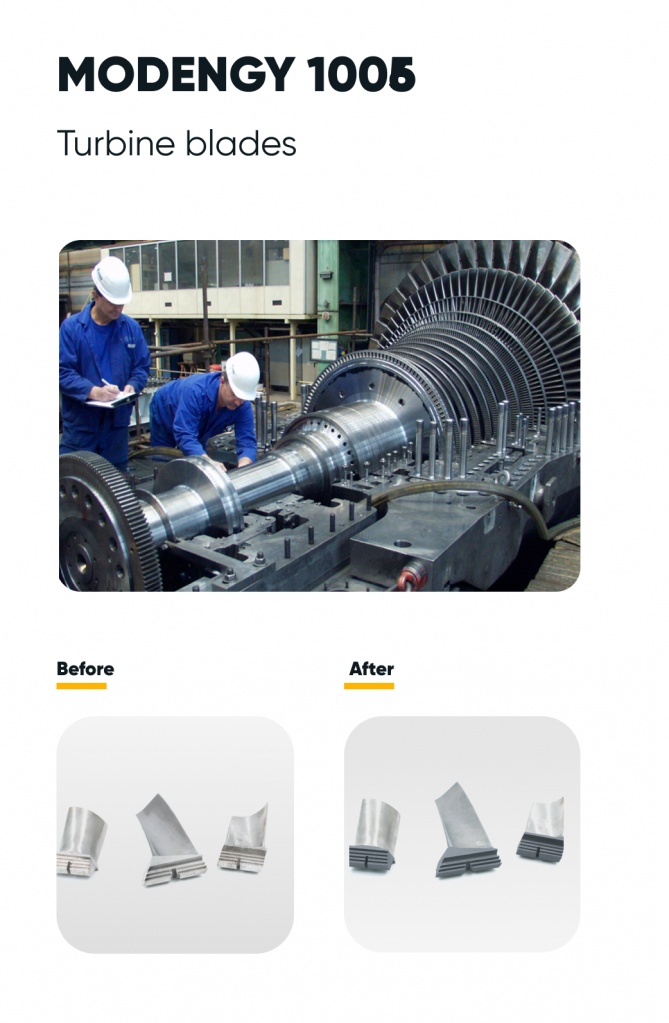

The turbine blade shank ends are treated with MODENGY 1001 coating to provide easy mounting and dismantling as well as a long-term service lifetime of the elements.

Fig. 2. Turbine blades in their initial state, and after applying MODENGY coating

MODENGY 1001 and MODENGY 1007 are applied onto the steam pressure relief valves of the heat power stations. Due to this, reducing friction and wear of the controlling mechanisms of the high-temperature devices is provided.

Fig. 3. The locking valve parts covered with MODENGY coating

The gas turbines slide bearings are treated with MODENGY 1001 and MODENGY 1002 coatings. They provide low friction coefficient of the parts, improve sliding, and prevent stick-slip motion, extend service lifetime of the mechanism.

MODENGY 1005 is used on the press fits. It protects the parts against damages at pressing, makes mounting easier.

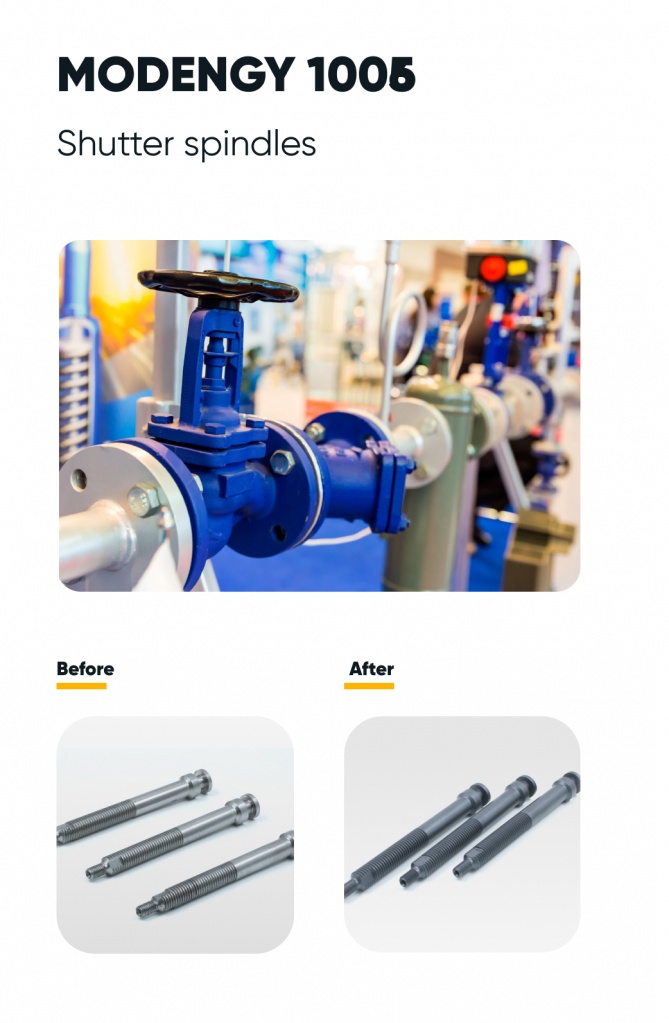

MODENGY 1001 product is used for lead screws. Due to this, friction coefficient of the elements reduces, sticking and scuffing are prevented, smooth running improves, force on the shutter drive decrises.

Fig. 4. Shutter spindles in their initial state, and after applying MODENGY coating

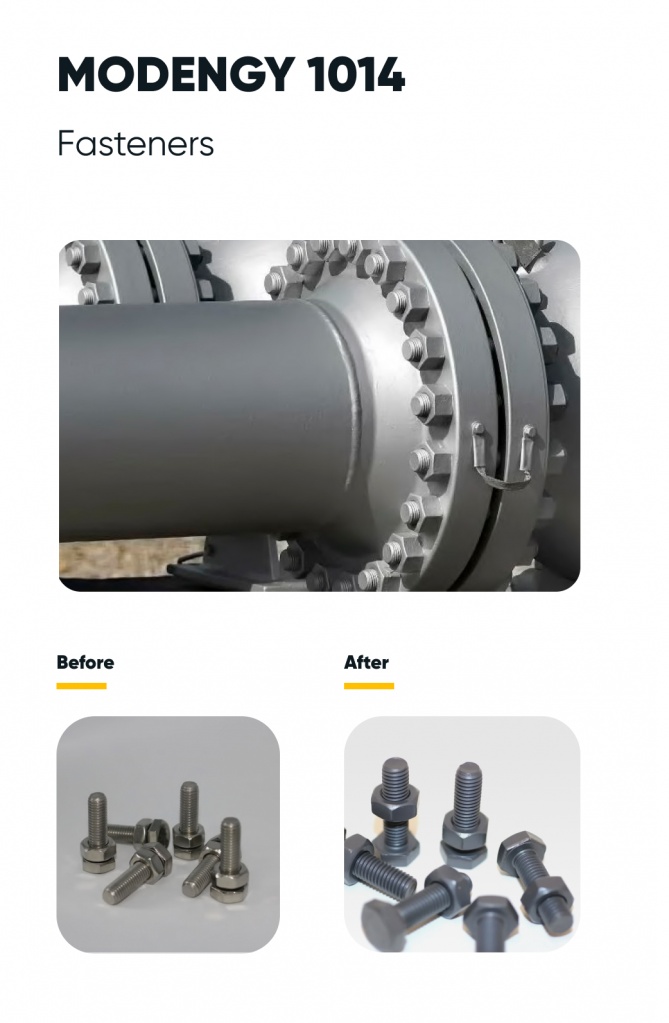

The energy turbines fasteners are coated with MODENGY 1014 agent. It provides easy connection mounting and dismantling, stable tightening force, reducing and stabilizing friction in the thread, corrosion protection.

Fig. 5. Fasteners in their initial state, and after applying MODENGY coating

MODENGY 1001 AFSFL is applied onto the condensate tappers of the stop valves.

The mentioned coatings have high upper limit of service temperatures, and protect the parts against damages at overheating. The anticorrosive and anti-friction properties of the materials provide significant extend of the service lifetime of the equipment.

The AFSFCs have a long-term service life, and require no constant refreshing. A thin layer of the materials (15 to 25 micron) make no significant affect to the final dimensions of the parts.

It is possible to treat the elements already at the stage of their production.

The Modengy company provides services on selecting its coatings for the certain units of the turbine. Applying the materials is performed at the specialty engineering center on the company’s base. It is also possible to get training on how to use the coatings independently.

For more detailed information, and to get a consultation, please contact our experts.

Request information

RU

RU

EN

EN