The remotely piloted flying devices are called in different ways including copters, pilotless ones, RPFDs, drones, etc. These devices are able to move over air without any staff on board, and are used for various purposes.

The modern drones are different on distance and way of flight, the heaviest possible load to be moved, method of control as well as other performances.

A set of useful properties makes using remotely piloted flying devices efficient in various fields starting with solving military, and fire-rescuing tasks and ending with monitoring the opencast mines, and inspecting the hard-to-reach place at the stations on mining hydrocarbons.

The RPFDs are controlled with a computer, smartphone, or remote control (remotely coordinated devices), or with a program uploaded into an on-board computer (apparatuses with automated control).

The first drone prototypes appeared at the end of the 19th century, and were designed for military purposes. In Russia, their production started in the 70s of the 20th century.

The RPFDs have different characteristics, and nevertheless some basic properties are in the basis of operating of any of them such as:

- Independent moving over space

- Keeping up the given altitude and flight speed

- Load-carrying capacity

- Registering and transmitting data to an operator

Dusty and humid environment inevitably influences the state of RPFD’s case and mechanisms. In the course of time many of them wear, corrosion appears on the metal elements, dirt builds up on the rubber and plastic units.

To improve reliability and extend service lifetime of the remotely piloted flying devices elements it is necessary to apply innovative lubricating materials.

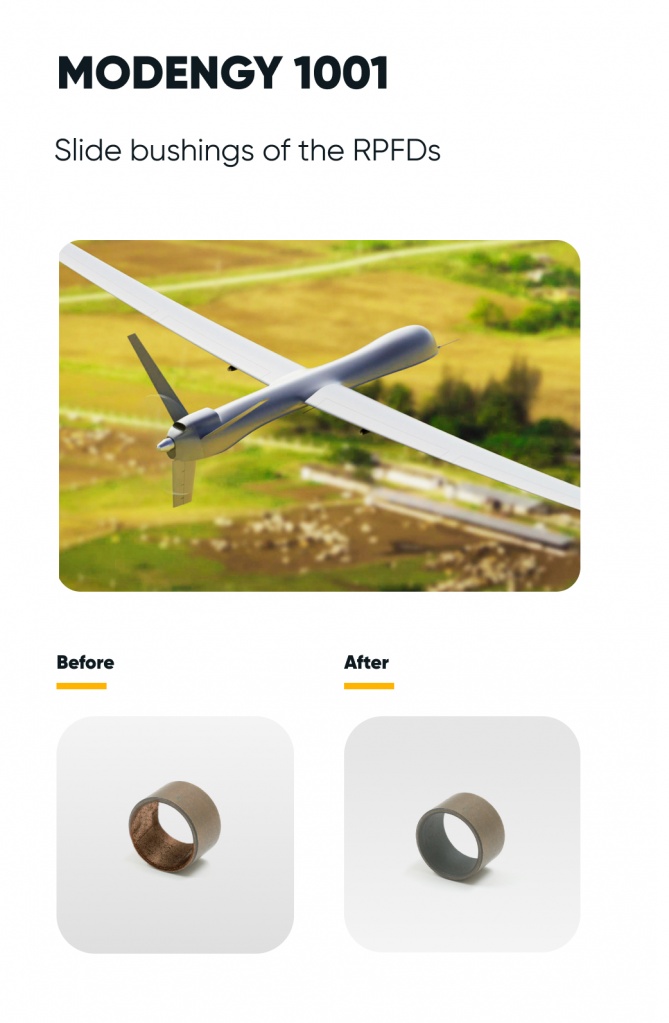

The Modengy company has suggested its solution to the RPFDs’ designers. MODENGY PTFE - A20 and MODENGY 1001 anti-friction solid-film coatings are applied onto the sliding friction units of the drones. The dry protective layer got as a result reduces wear of the contacting surfaces, improves working reliability, and extends service lifetime of the flying devices in general.

MODENGY 1014 is used to treat fastening parts. A resistant layer of this material makes process of mounting and dismantling the connections easier, stabilizes friction, prevents scuffing, jamming, thread galling, protects the elements against corrosion.

The technology of applying these materials is easy to implement - any painting method will suit. Single treatment of the items is enough to create the units and mechanisms that require no further maintenance.

The Modengy company provides services on applying its materials at the Engineering Center located in Bryansk town.

For more information about using the anti-friction solid-film coatings contact the Modengy company by clicking the Request Information button below.

For more information about using the anti-friction solid-film coatings contact the Modengy company by clicking the Request Information button below.

Request information

RU

RU

EN

EN