A lot of factors affect efficiency and operating term of car units. So, high temperatures and higher friction cause wear of engine parts, vibration and shock loads affect suspension components in a negative way, precipitations and mud provoke open units corrosion.

In order to provide reliable operating and long service lifetime of friction surfaces, the lubricating materials are required to be selected taking into account the pointed factors affection.

The greases and liquid lubricating materials conventionally used in the units of machinery have tendency to oxidizing, aging, in process of operating they are subjected to washing-out, contamination (attract dust and abrasive), and flowing-out.

Image source: Sternstunden / www.shutterstock.com/ru

Therefore, a special king of lubrication compounds - anti-friction solid-film coatings - are used instead of those materials, or in addition to them. They provide long-term (frequently lifetime long) lubrication of the parts improving their operating reliability, and minimizing risk of premature failure of the units.

Advantages of using MODENGY coatings in car units

MODENGY anti-friction solid-film coatings are designed and produced by the Russian Modengy company by their own technology.

They consist of binding components, highly dispersed particles of solid lubricating materials, functional additives and solvents.

The coating gets cured after being applied onto preliminary prepared surfaces. A thin dry lubricating-and-protective film forms on the parts that has high wear-resistance and load-carrying capacity.

MODENGY coatings are widely common in the units of cars, due to their following properties and advantages:

- Low friction coefficient – from 0,03

- Wide service temperature range: -210 to +730 °С

- High load-carrying capacity – up to 3,000 MPa

- Thin layer thickness – 20 µm

- Long service lifetime

- Anti-scuffing properties

- Resistance to chemically aggressive substances

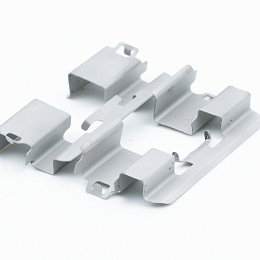

MODENGY anti-friction solid-film coatings can be applied onto the parts of very various configuration. Due to thin layer thickness, they can be used at mass production of the components without their size correcting

MODENGY coatings application at cars production and repairs

MODENGY coatings find their application virtually in all car systems – from engine parts and suspension to car interior.

These products are used at mass production of automotive components at plants as well as can be used during machinery repairing including for the purpose of restoring the plant coating.

So, a machine engineering enterprise that is one of the leaders on the automotive components market has implemented MODENGY coating based on molybdenum disulfide and graphite into mass production of their items, and specified application of this material in the design documentation after having received positive test results.

This coating reduces friction, makes easier assembly and disassembly of the connections operated under conditions of high temperatures.

MODENGY anti-friction solid-film coatings are also used on the following automotive parts:

RU

RU

EN

EN