It's hard to find an aspect of life in the modern world where polymers are not used. Their use allows to reduce weight and cost, to extend service lifetime, and to improve other properties of the items.

Polymer materials:

- Are not subjected to corrosion

- Have low weight

- Have high strength

- Easily take on a required form

- Are resistant towards chemicals

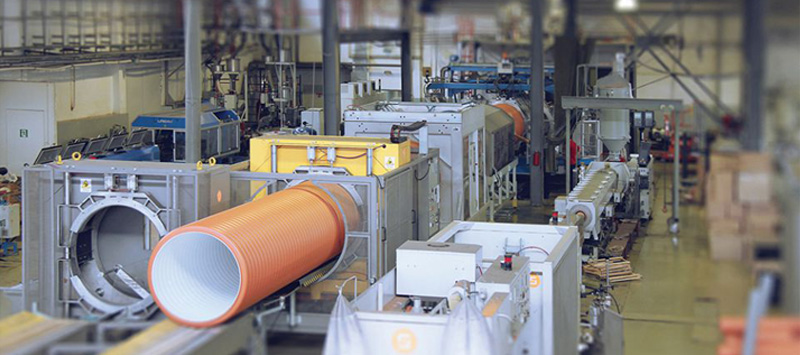

Fig.1. Extrusion line

However, a number of issues arises while using this method related with sticking the material onto the moulding equipment, forming carbon deposits, unstable heat exchange. MODENGY coatings help solve them.

Typical issues at operating the equipment for producing items of polymers

Extruder knife element is one of the main elements of the line on processing and producing items of polymers. Quality of the ready products depends on its reliable and stable operation.

Increased carbon deposits forming on the contact surfaces of the moulding elements is the main reason to stop the technologic line on processing polymer raw materials. This is caused by breaking heat exchange process when the molten mixture moves.

Increasing polymer raw material deposits on the moulds, moulding heads, matrices, and spinnerets leads to decreasing end product quality, increases risk of mechanisms downtimes for unscheduled repairs.

Here are the equipment operation failure causes at producing goods of polymer materials:

- Increased forming carbon deposits on the moulding accessories surface

- Poor conveyance capacity of matrices and calibrators

- Moulds and spinnerets contact surfaces damage

- Heat exchange violation

- Difficulties with separating the products from the moulds

- Defective products, recycling costs

MODENGY coatings for extrusive equipment

MODENGY anti-adhesion and non-stick coatings are used to provide stable function of the extrusion systems. Application practice and reveals that they:- Prevent sticking polymer raw materials onto the accessories

- Decrease risk of unscheduled repairs and equipment stoppage to minimum

- Reduce energy costs

- Increase item quality and cut down defective items quantity

- Don’t hinder heat exchange due to small layer thickness of 15 to 25 µm

- Operate within wide temperature range

- Have long service lifetime

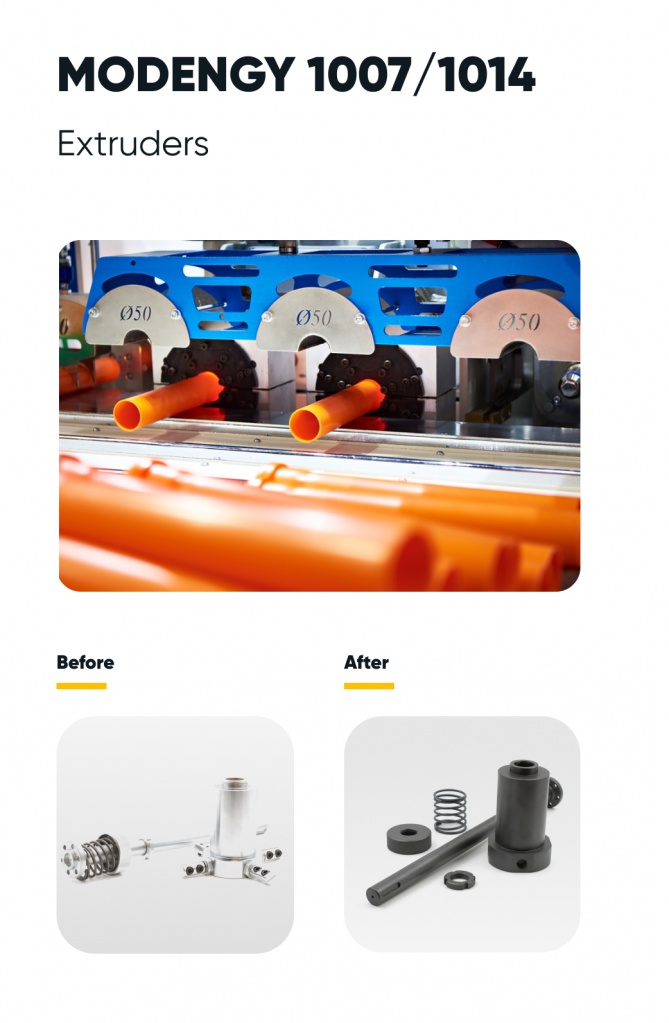

The product line of the agents for extrusion equipment surfaces protection includes MODENGY 1007 and MODENGY 1014 coatings. They are applied onto the contact surfaces of the knife unit, and moulding accessories elements by spraying method. These coatings create strong dry separating layer of the solid lubricating materials' particles. They are resistant to mechanical impact, aggressive environments, and detergent solutions.

Fig.2. The units of extruder in their initial state, and after applying MODENGY coating

MODENGY 1007 is an anti-adhesion and non-stick coating based on graphite. It stabilizes heat exchange on the contact surfaces, and has high wear resistance. This product of grey-and-black colour cures at +200 °С within 20 minutes.

MODENGY 1014 is a coating based on polytetrafluorethylene. It effectively improves heat exchange, and makes separation of the items from the moulds easier.

Conclusion

MODENGY 1007 and MODENGY 1014 coatings have a number of advantages over the conventional lubricating materials. They:

- Have unique separating properties

- Operate within wide temperature range from -75 °С to +350 °С

- Are resistant to aggressive media exposure, and long-term mechanical impact

- Provide stable heat exchange between contact surfaces

- Lower risk of forming carbon deposits to minimum

- Are characterized of high wear resistance at cyclic loads

- Have long service lifetime on the production accessories surface

For more details and consultation please contact us by clicking the button.

Request information

RU

RU

EN

EN