The agricultural machinery operates under complicated conditions related to large work volumes, high load on the mechanisms, dustiness. The local climate conditions have a great influence.

Terms and quality of harvest picking up depends on stable functioning of the devices. The machines are examined before going out to the field to make sure they are in good working order.

Regular mechanisms state check and lubrication prevents their failure and break. According to statistics, repairsexpenses make 15 to 20 percent of agriculture equipment cost.

Basic issues at agricultural machinery operating:- Dust sticking onto the mechanisms leads to their abrasive wear

- Atmospheric precipitation causes parts corrosion

- Vibration and shock loads become the cause of the premature wear

Specialty service materials are used at production and maintenance of the machinery to prevent this. They areapplied onto the basic friction units of the mechanisms. The tasks of these agents are reduced downtimes caused by technical reasons, and increasing machinery efficiency.

Greases and liquid lubricants are traditionally used for this purpose. However, a number of issues arise at usingthem: they are washed out, lead to dust sticking, don’t protect against corrosion. Service lifetime of such materials is not long, sometimes they are have to be renewed under field conditions. These equipment downtimes cause large time and financial losses.

An alternative possible is using MODENGY anti-friction solid-film coatings. MODENGY 1002, MODENGY 1005, MODENGY 1006, MODENGY 1014, MODENGY For ICE Parts are used for agricultural machinery production and maintenance.

- Dry lubrication technology realization. It doesn’t stimulate abrasive wear

- Longterm lubrication. The properties of these materials remain for the whole service term of the parts

- High corrosion protection (up to 720 hours, according to the sped test in salt mist. DIN EN ISO 9227 Standards)

- Protection against scuffing

- High load carrying capacity (up to 2,500 MPa, SRV friction machine)

- Coating thickness of 15 to 25 µm makes no effect to the parts dimensions

Application Examples

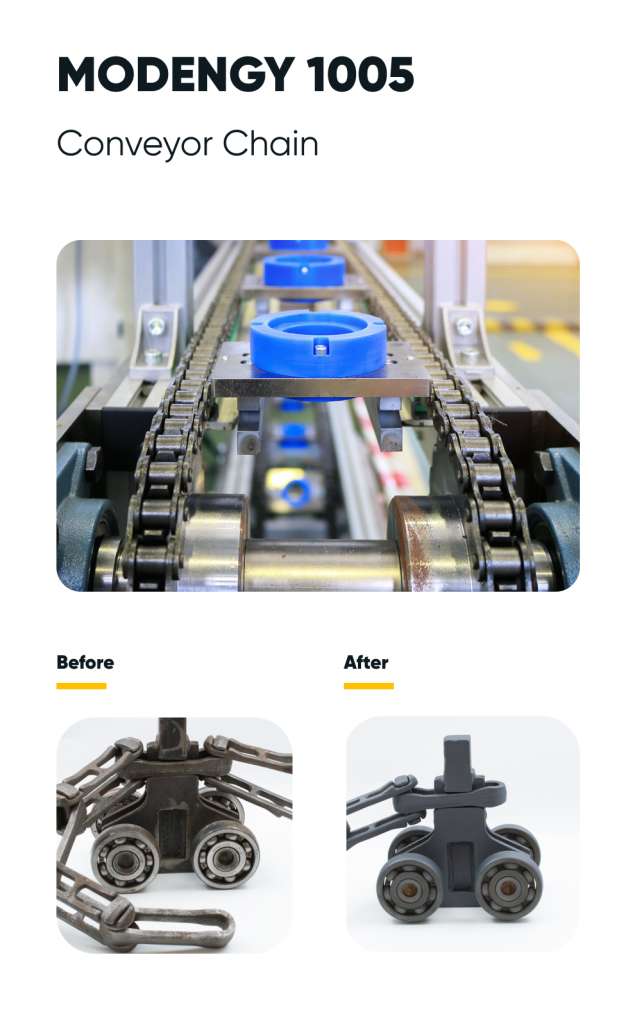

MODENGY 1005 is applied onto the axis and bushings, worm gears and dismountable drag-chains of the agricultural machines.

Friction on the axes and bushings becomes stable, and stick-slip motion is prevented. Due to this, wear of the hinge joints reduces.

The separating layer of solid lubrication reduces wear, and increases efficiency coefficient of worm pair even athigher loads and temperatures.

The coating is applied onto all elements of the dismountable drag-chain. It reduces friction and wear, protectsthe parts against corrosion.

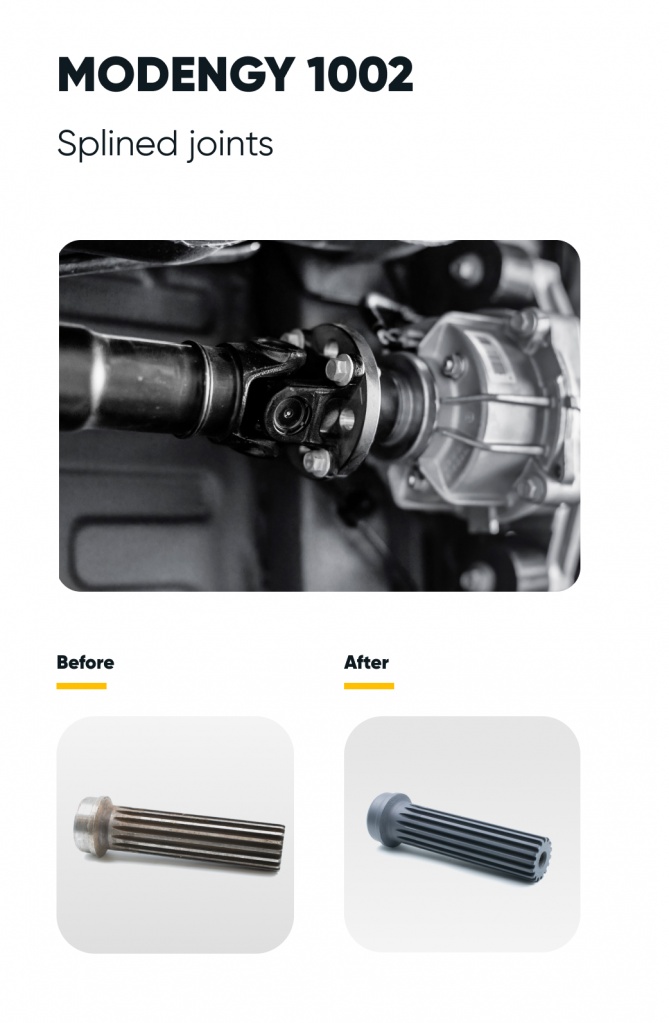

MODENGY 1002 is applied onto the shaft splined joints. The separating layer makes shaft fit easier, reducesparts friction and wear at moving along the splined joint.

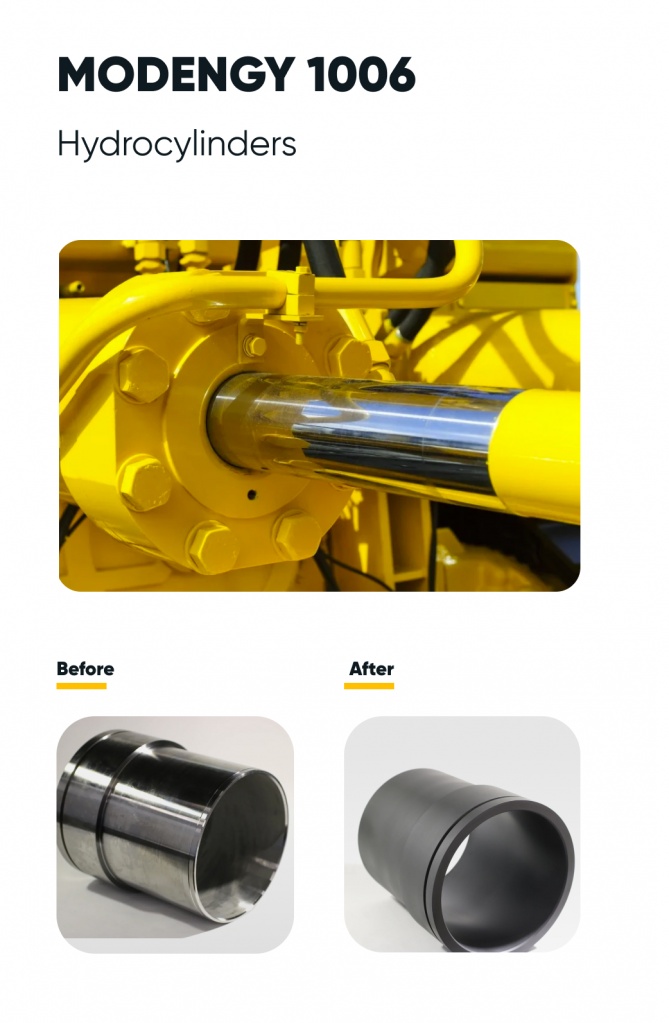

MODENGY 1006 coating is used on the hydraulic cylinders. It prevents stick-slip motion, reduces friction losses,improves tightness of the connection. This product is resistant towards hydraulic oils.

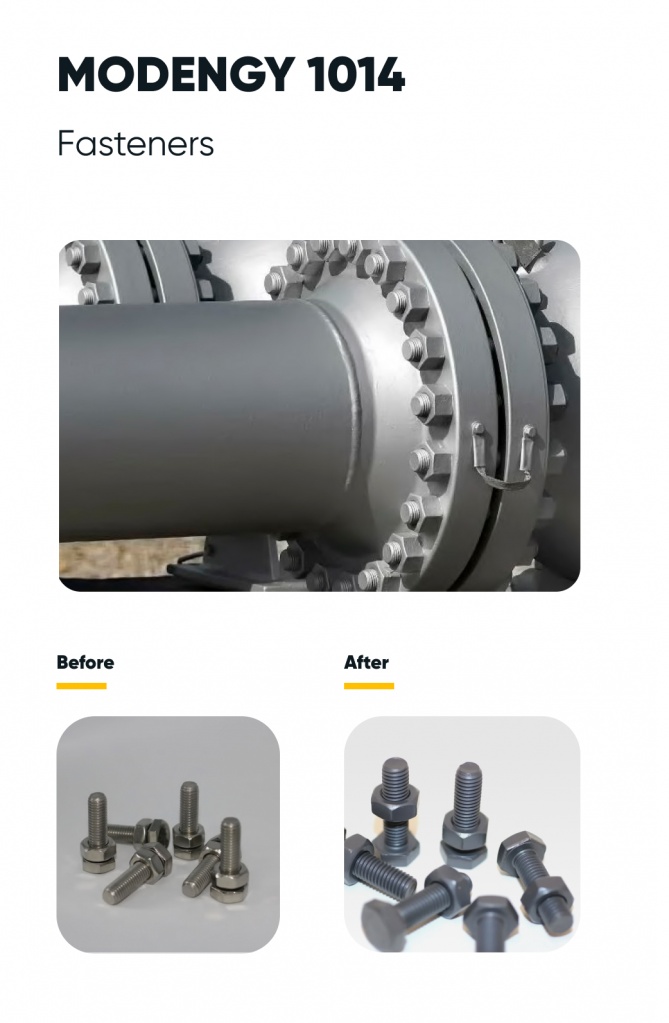

Reliable machinery functioning directly depends on fastening items quality. MODENGY 1014 coating based onmolybdenum disulfide and polytetrafluorethylene protects the fastener parts against corrosion, and aggressive media impact. It stabilizes friction, prevents thread galling, scuffing, and jamming.

MODENGY For ICE Parts is applied onto the tractors and combines engine piston skirts. Due to this, scuffing atoverheating, at higher loads, at engine starting at negative temperatures are prevented.

Use of MODENGY anti-friction solid-film coatings to maintain mechanisms of the agriculture machinery enablesto significantly extend its service lifetime, reduce parts friction, and increase resistance towards aggressive exposures. The resistant separating layer retains its properties for the whole operation term of the parts. Due to this, time periods for machine downtime and repairs cut down considerably, and financial costs also minimize.

For more details and consultation please contact us by clicking the button.

Request information

RU

RU

EN

EN