Protection of end-soldering elements

of packaging equipment

by using MODENGY anti-adhesive

and separating coatings

Protection of end-soldering elements of packaging equipment

by using MODENGY anti-adhesive and separating coatings

Sticking

prevention

Protection against

carbon deposits

MODENGY coatings

Operate as long and efficiently

as possible

as possible

They withstand high temperatures up to +350 °С

They are not destructed by detergents and chemicals

They are hold strongly on the surface of the end-soldering elements

They are easy to apply

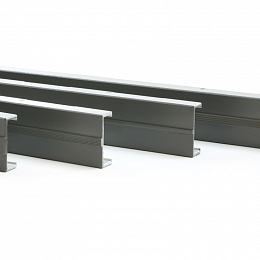

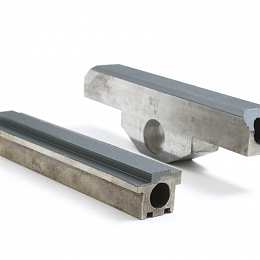

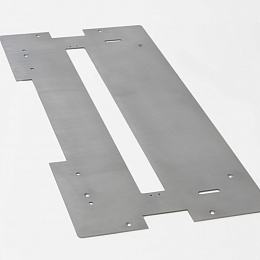

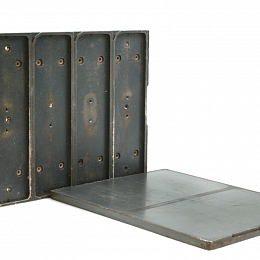

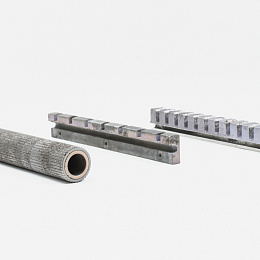

Examples of our works performed

Troubles at operating

packaging equipment

Film and its melted remnants sticking to the end-soldering elements

Film poor sliding and crumpling on the packaging sleeve-forming collars

Wear of the factory Teflon coating

Protective coating peeling and destructing at overheating of the end-soldering elements

Frequent equipment halts to lubricate and clean off carbon deposits

ALL THIS CAUSES WORSE PACKAGE QUALITY,

AND DEFECTIVE ITEMS AMOUNT GROWTH

AND DEFECTIVE ITEMS AMOUNT GROWTH

Videos

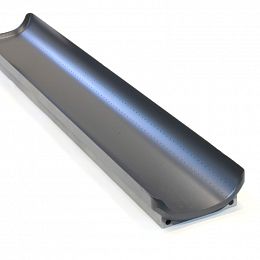

MODENGY 1007

Coating based on new polyamide-imide polymer

It has high anti-corrosive properties

Non-toxic

Single application of the coating is enough for trouble-free long term operating of the equipment

It forms an anti-sticking separating layer on the surface

It is resistant to aggressive detergents and chemicals that might be used to clean the end-soldering elements

It restrain its properties at up to +350 °С – it is resistant to unplanned overheats of the end-soldering elements

MODENGY PTFE-A20

Anti-friction solid-film coating based on polytetrafluorethylene (PTFE)

Non-toxic

It has high anti-corrosive properties

It cures fast at room temperature

It prevents film sticking and improves its sliding

This translucent coating doesn’t spoil parts appearance

It is easy to apply by spraying out of an aerosol can

It is operable up to +130 °С

RU

RU

EN

EN