Hydrocarbon offshore extracting, especially at the northern latitudes, are performed under severe conditions such as corrosively active environment with increased humidity and temperature drops.

The equipment used for this purpose must be reliable and durable. Related to this, the solutions on extending service lifetime of the parts and mechanisms have been developing.

MODENGY anti-friction solid-film coatings technology

One of the most efficient solutions for the task on extending service lifetime and improving reliability of the oil platform equipment units is applying the anti-friction solid-film coatings (AFSFCs). They form a resistant layer on the parts surfaces that is a polymer matrix containing highly dispersed particles of solid lubricating materials such as polytetrafluorethylene, molybdenum disulfide, graphite, and some others.

A thin coating layer (15 to 25 µm) can perform various functions. It can operate as a separator between the surfaces with a high friction coefficient, perform the task on protecting the parts in the chemically aggressive environment.

These properties make the AFSFCs the unconditional leader in the issue of providing lubricating and protective functions in comparison with the conventional materials.

It is possible to use the innovative solid-film agents already at the stage of manufacturing the parts and mechanisms.

Examples of MODENGY coatings applications

MODENGY coatings are used to treat the threaded fasteners that is used at assembling metal constructions, pipelines, and valves.

Due to this, the following can be provided:

- Protecting against corrosion under condition of marine climate even after multiple mounting/dismantling the joints

- Preventing jamming and galling while tightening

- Stabilizing friction coefficient in the thread, and providing the required tension effort

- Eliminating ‘sticking’

Fig.1. The high-strength bolt sets coated with MODENGY 1014

MODENGY AFSFCs are used to extend service lifetime of the casing, drilling, and pump-compression pipes. The resistant solid-film layer saves time while performing the tripping-in and lifting-up operations (TLO), provides lubricating without using thread pastes (despite being compatible with them).

The layer of the anti-friction solid-film coating requires no renewing at every maintaining, is not squeezed out of the contact zones at high loads, emit no harmful evaporations. It effectively protects the parts against corrosion by replacing the conservation lubricants.

Fig.2. MODENGY 1002 coating appearance on the thread of the pump-compressor pipe and the clutch

There is a lot of attendant processing equipment in the well related to the threaded connections such as adaptors and clutches. The coatings are applied on them for the purposes of protecting against external factors exposure and to prevent scuffing.

The structure of any well intends fountain valves presence, that is a system of the various types stop-and-adjust valves connected with each other. The purpose of this mechanism is to adjust well operating, to stop it up, to redirect the fluid flows, drilling and washing solutions.

In this case, the coatings are used for the purpose of providing protection against corrosion at the minimal effort on moving the lead screw, the rack rod, axial type valve, or other drive.

Fig.3. The rack and the rod of the axial type valve with MODENGY 1005 coating on their functional surfaces

The AFSFCs are used at the preventer, the key element of the blowout system. It is in charge of sealing the mouth of the well at emerging dangerous situations. The agents are applied onto the internal surface of the preventer body to reduce friction coefficient of the moving elements, and to prevent sticking asphalt-tar-paraffin deposits.

The coatings have long service time what guarantees proper performance of the mechanism after a long downtime.

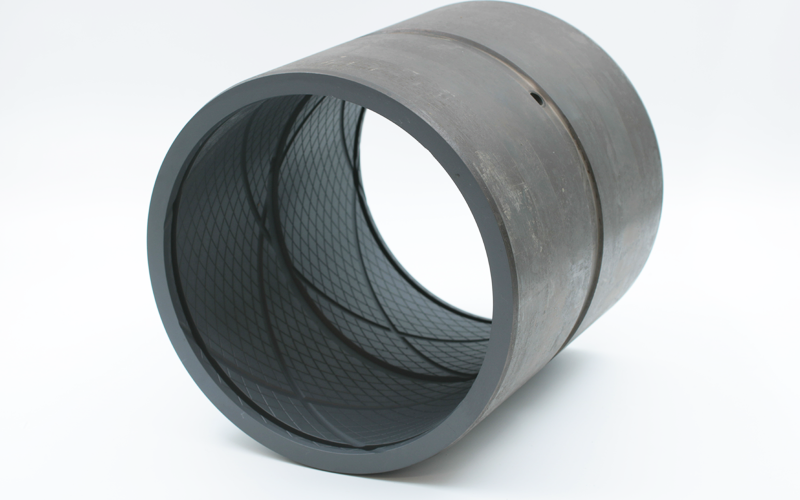

MODENGY products prevent wear of bearings and slide guideways of the oil platforms load-lifting mechanisms which service lifetime significantly cuts down because of the destructive corrosion processes that get stronger under marine conditions.

Fig.4. The load-lifting mechanism bushing with MODENGY 1005 coating on its internal surface

Fluid and grease-like lubricating materials are not effective in this case: they are squeezed out of the zones of applying at high loads. The AFSFCs form a dry layer that has increased load carrying capacity and retain their properties even at significant contact pressures.

MODENGY coatings for the platforms equipment

- Solid lubricating materials in the composition: molybdenum disulfide and graphite

- Service temperatures: -210...+320 ºС

- Friction pair: metal-to-metal

- Corrosion protection according to DIN EN ISO standard is more than 160 hours

- Features: polymerization without heating

- Solid lubricating materials in the composition: molybdenum disulfide

- Service temperatures: -200...+255 ºС

- Friction pair: metal-to-metal

- Corrosion protection according to DIN EN ISO standard is more than 720 hours

- Features: high load carrying capacity

- Solid lubricating materials in the composition: molybdenum disulfide and graphite

- Service temperatures: -200…+315 ºС

- Friction pair: metal-to-metal

- Corrosion protection according to DIN EN ISO standard is more than 300 hours

- Features: high heat resistance

- Solid lubricating materials in the composition: molybdenum disulfide and polytetrafluorethylene

- Service temperatures: -200…+255 ºС

- Friction pair: metal-to-metal, metal-to-polymer

- Corrosion protection according to DIN EN ISO standard is more than 672 hours

- Features: compatibility with polymers

- Solid lubricating materials in the composition: polytetrafluorethylene

- Service temperatures: -70…+130 ºС

- Friction pair: metal-to-polymer

- Corrosion protection according to DIN EN ISO standard is more than 160 hours

- Features: polymerization without heating

MODENGY coatings are developed and produced by the Russian Modengy company. Its wide product range contains the agents effectively solving the tasks applicable to oil industry equipment. The materials are simple and convenient to be applied while a small layer thickness does not affect the final dimensions of the parts.The coatings can be applied either by yourself, or you can use the services of the workshop on coatings applying in Bryansk.

For more detailed information, and to get a consultation, please contact our experts.

Request information

RU

RU

EN

EN