Use the service on applying the coatings

at MODENGY Engineer Center

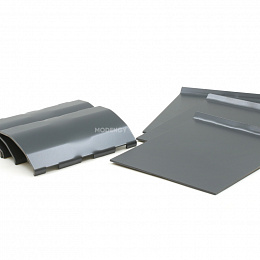

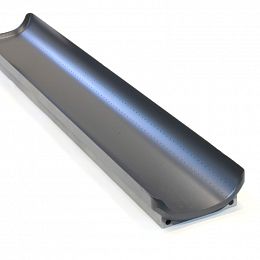

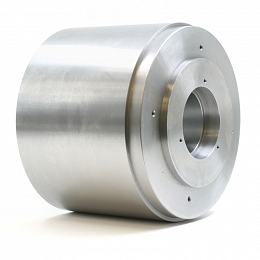

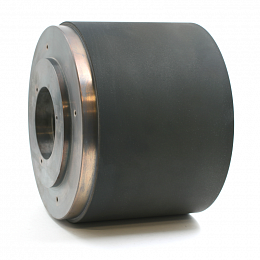

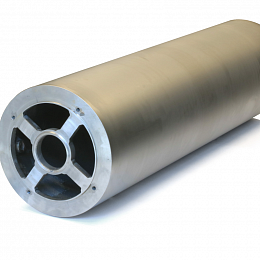

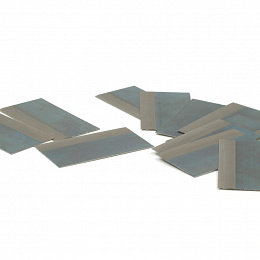

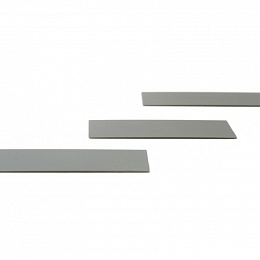

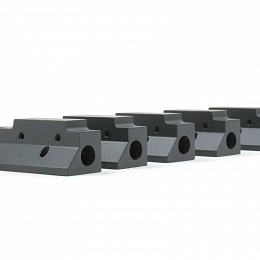

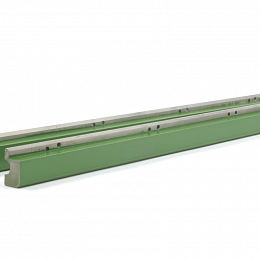

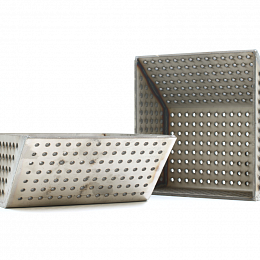

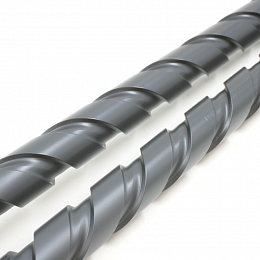

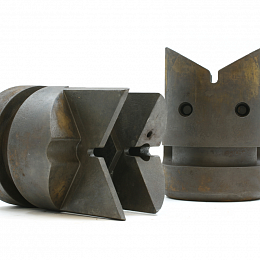

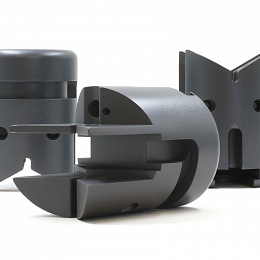

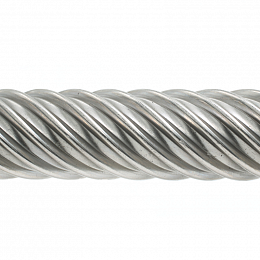

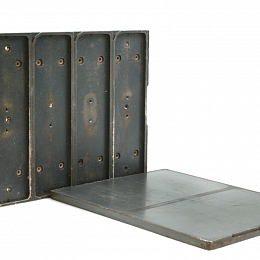

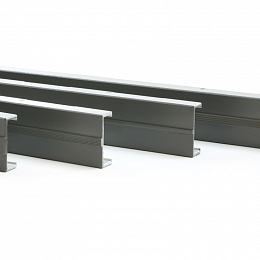

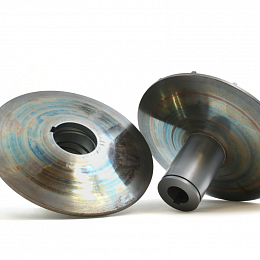

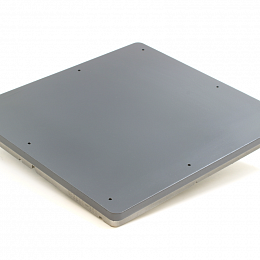

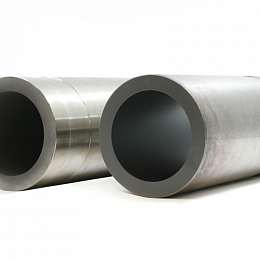

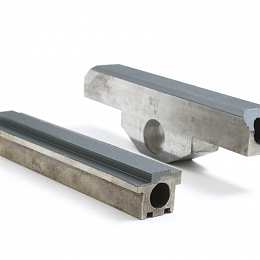

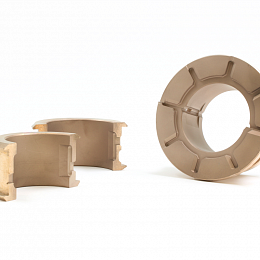

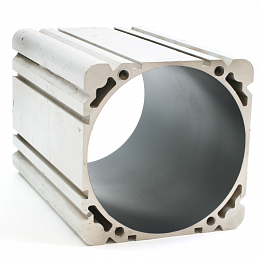

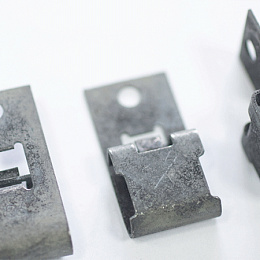

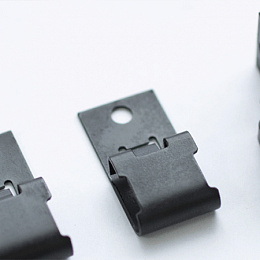

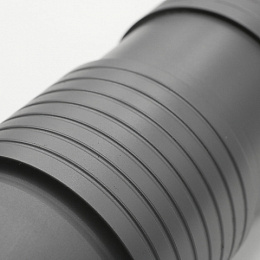

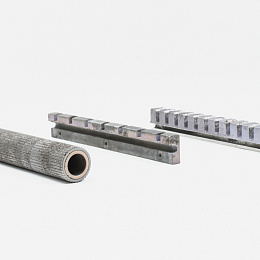

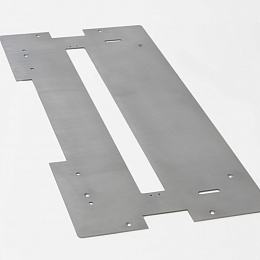

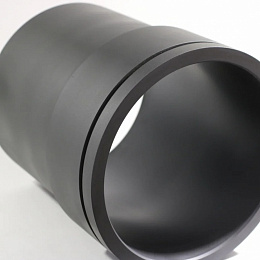

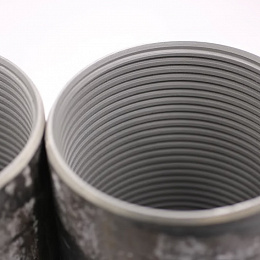

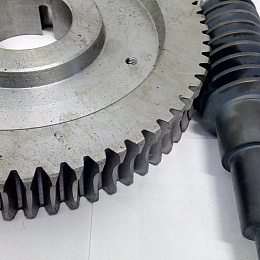

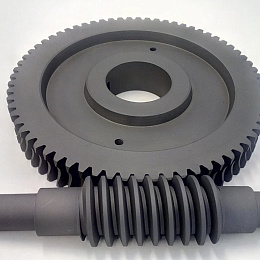

The Modengy company provides services on applying anti-friction solid-film coatings onto the components of various configurations, dimensions, and weight.

Possibilities of our Engineer Center

on applying coatings

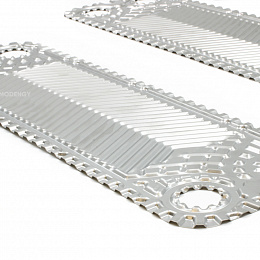

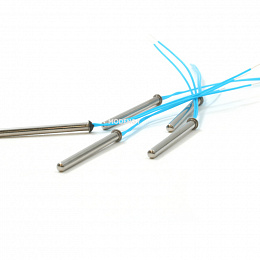

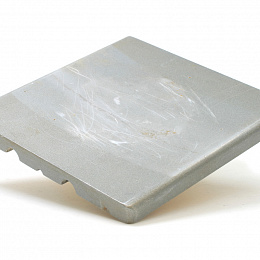

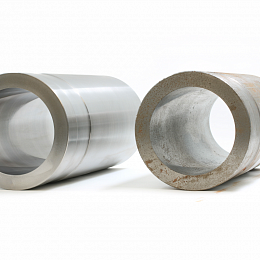

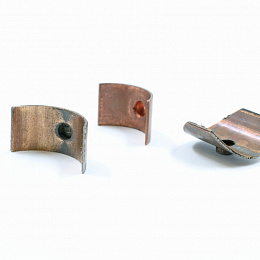

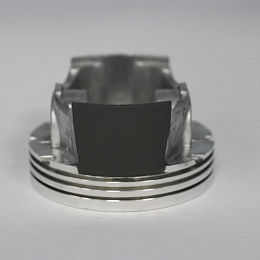

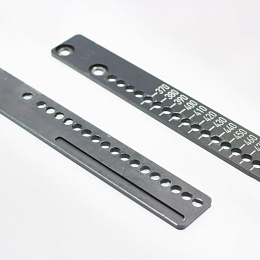

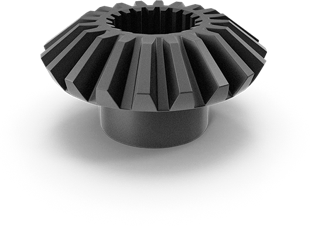

Evaluating part surface quality

quality parameters is held. This is necessary to provide requirements towards

coating adhesion and service duration. According to the evaluation results,

conclusions on further optimal surface preparation are formed.

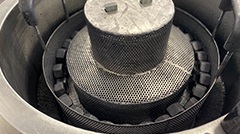

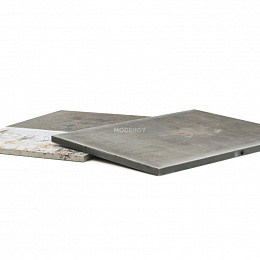

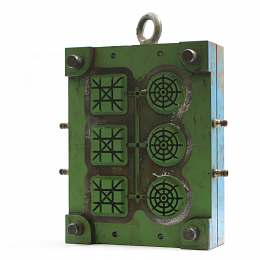

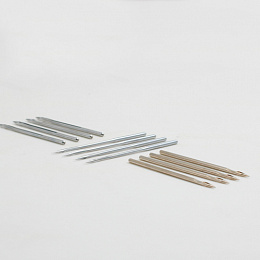

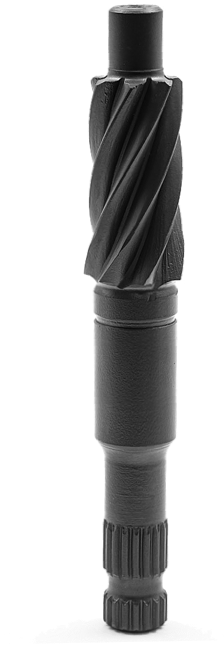

Surface preparation by chemical and mechanical methods

surface as possible. For this purpose, both mechanical and chemical effects to the surface

layer are used. This enables not only clean the surface from contaminations and oxide

films but also form an optimal surface microrelief. The company experts develop and realize

customized preparation methods according to each customer’s requirements.

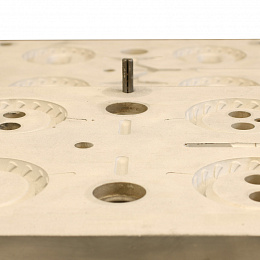

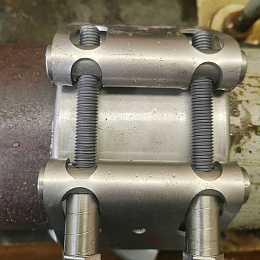

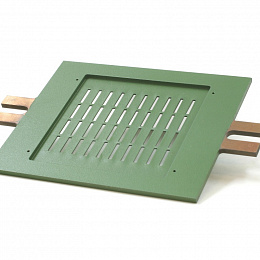

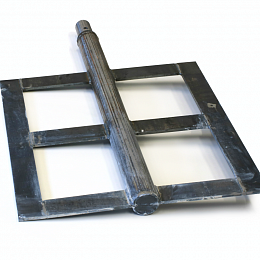

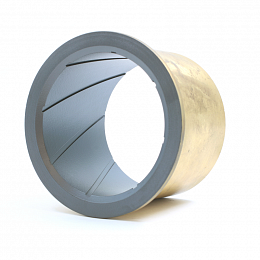

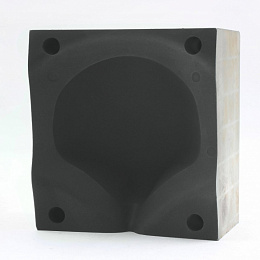

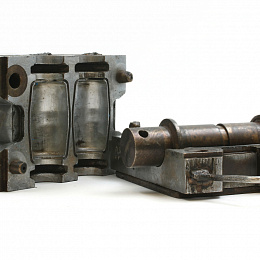

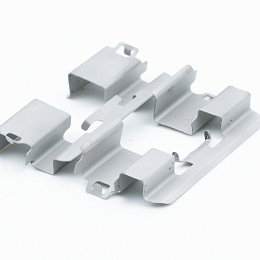

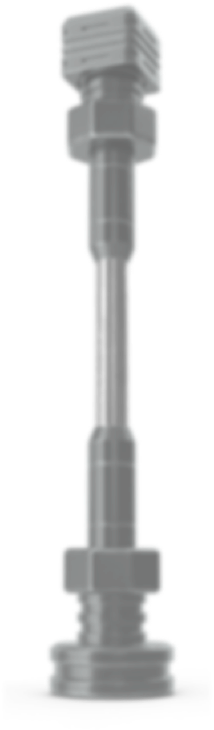

Coating applying by the method that takes into account part configuration and dimensions

location on it, developing the technological process of anti-friction coating applying is held.

Such parameters as mass or single production it is going to be, and volume of the certain batch of the parts to be covered are taken into account. The company experts develop technological process both for unique single item samples and for large series.

RU

RU

EN

EN